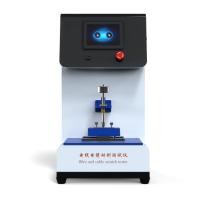

huitao HT-1079 Wire and cable resistance Tester DATASHEET

Specifications

| Friction method | reciprocating |

| Frictional contact form | line |

| Meet the standard | ISO6722、GBT25085、JIS C 3406、JASO D611 |

| Operating interface | Color 7-size touch screen, Chinese and English switching |

| Needle diameter | (0.25 +/- 0.01) mm or (0.45 +/- 0.01) mm according to customer and supplier agreement |

| Needle Frequency | (55 +/- 5) cycles per minute (one cycle includes a reciprocating motion) |

| Needle displacement | (20 ± 1)mm |

| Abrasion length | (15.5 soil 1) mm |

| movement type | The design details should not affect the test results |

| Mass (location, value, design details) | The vertical force of the specimen is constant under dynamic conditions |

| Sample installation force | The specimen must not be moved during the test. If it needs to be fixed, the tension on the wire must not exceed 100 MPa (N/mm2). |

| number of trials | 0-99999999 times (can be preset and power-off memory function) |

| shutdown device | When the scraper needle wears through the insulating layer and comes into contact with the conductor, the equipment automatically stops |

| Scraper needle load | 800G, 900g, 1000g, 1100g according to the actual selection of customers |

| Load Weight | 300G, Weight 100g, 200g, 500g, 65, 105, 155, 210, 270N each can be stacked according to the actual selection of customers |

| Machine size | 420mm×450mm×680mm |

| Machine Weight | 35kg |

| stop function | Will automatically stop |

| Power Supply | AC220V、50Hz |

| Scrape length | 15.5mm |

Packing list

After-sales instructions

Warranty days: 365 days

1. For product quality problems caused by non-human products of instruments and equipment, the manufacturer will provide free warranty services during the warranty period;

2. There is no warranty period for fragile and consumable parts, and if you find product quality problems after receiving the goods, please apply for return and exchange within 7 days, and you will not wait for the overdue ones;

[Note] For after-sales services outside the Chinese mainland, if the instrument requires repair, the shipping and possible associated taxes shall be borne by the sender. Generation address of the manual: http://en.nbchao.com/p/48281/Specification.html , which is only used by users who purchase commodities from the NBCHAO.

Created on : 2026/02/20