HuiNuo HN-22 Production Full Explosion-Proof Basket Grinder with 500L Stainless Steel Barrel

22Kw, full explosion-proof type, containing 500L stainless steel barrel, frequency conversion speed regulation, hydraulic lifting, with φ 500 stainless steel double-decked chilled down cylinder, spindle grinding sleeve for special factory customized PTFE removable sleeve, wear-resistant, heat dissipation fast.

HuiNuo

HuiNuo-

Muxuan MXY-C4000-40 Lab Basket Grinder 4000W/40L

$ 3426.00 -

MODERNER LSM-2.2B basket sand mill, frequency conversion explosion-proof 20L

Login -

HUXI HMD-400 Multifunctional Freezing Grinding Instrument 8 Hole × 0.2ml Round PTFE Adapter

$ 5488.00 -

HUXI HMD-400 Multifunctional freezing grinding instrument, double tank grinding

$ 5124.00 -

Muxuan MXY-C2200-20 Laboratory Basket Mill Frequency Conversion Speed Regulation 2200W with 20L Barrel

$ 2719.00

Introduction

The HN-22 Production Basket Mill is an efficient, fully explosion-proof industrial equipment suitable for a wide range of batch refinements. Its main motor power is 22kW, using vertical frequency conversion speed regulation system, which can be used to investigate the grinding range of 0-1450 rpm, and the motor is guaranteed for three years to ensure long-term stable operation. The elliptical is forged in solid stainless steel, the grinding basket is made of SUS304 material and has been quenched with high precision, Manhattan is about 20L, equipped with a filter cover and interference suction function, and the filter plate is formed by wire cutting to ensure high precision. The milling grinding sleeve adopts a wear-resistant, fast and customized PTFE induction sleeve.

Features

Fully explosion-proof, the main motor 22KW-4P vertical frequency conversion speed regulation. The motor is guaranteed for three years.

Frequency conversion speed regulation speed adjustable: 0-1450 rpm.

The spindle is made of solid stainless steel forging.Filter plate wire cutting molding.

Grinding basket SUS304 high-frequency quenching, volume: approx. 20L, with filter cover, turbine suction.

The spindle grinding sleeve is a customized PTFE detachable sleeve for the special factory, which is wear-resistant and fast in heat dissipation.

Hydraulic lifting 1.1kw pumping station with lifting limit switch, lifting stroke 1200mm.

With φ500 stainless steel double-layer cooling cylinder, inner cylinder SUS304 outer layer 304 stainless steel with dust cover, DN25 water inlet and outlet, DN50 outlet, national standard wire mouth.

With floor-mounted power distribution cabinet, built-in inverter, switch button, lifting control system, voltmeter, contactor, etc.

Do dynamic balance debugging before leaving the factory, high speed 1450 rpm debugging, wiring ready to use.

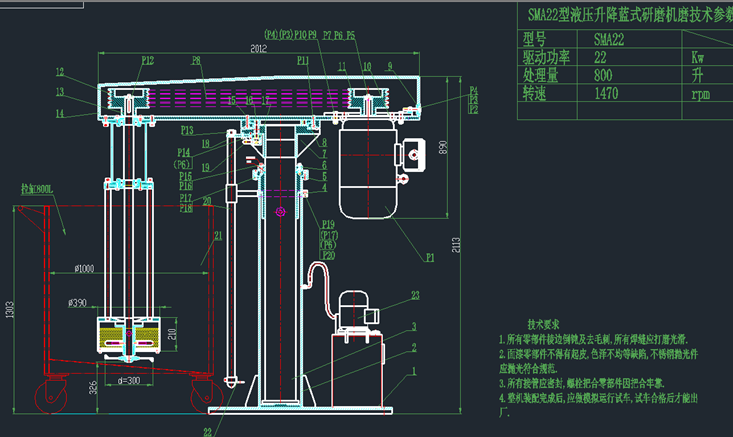

Product structure diagram

HuiNuo HN-22 Basket GrinderSpecifications

| LIST | VALUE |

|---|---|

| Motor Power | 22kw |

| Speed range | 0~1450 rpm |

| Lifting stroke | 1200mm |

| Effective Volume of sand grinding basket | About 20L (with filtrate cover, turbine suction) |

| dielectric diameter | 1.8~2.5mm |

| Barrel Volume | 500L |

| Dimension | Subject to actual customization |

| Power Supply | 380V |

| Weight | 1200kg |

| Lifting method | Hydraulic lift (pump station with lift limit switch) |

| Processing Capacity | 200~800L |

| Hydraulic Power | 1.1kw |

| Chill down cylinder | 500Mm stainless steel double-decked chilled down cylinder |

| Inner cylinder material | Inner cylinder sus304, outer 304 stainless steel, with dust cover |

| Is it explosion-proof? | Fully explosion-proof |

| Motor quality assurance | 3 years |

| Spindle grinding sleeve | Manufacturer customized PTFE removable sleeve, wear-resistant, fast heat dissipation |

| Spindle material | Solid stainless steel forging treatment |

| Grinding basket material | SUS304 high frequency quenching |

| Filter plate | Wire cutting |

| inlet and outlet | DN25 |

| Discharge port | DN50, national standard silk port |

HuiNuo HN-22 Basket Grinder Packing list

Grinder x1, 500L stainless steel barrel x1, floor-to-ceiling distribution cabinet x1, manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

HN-22

HN-22