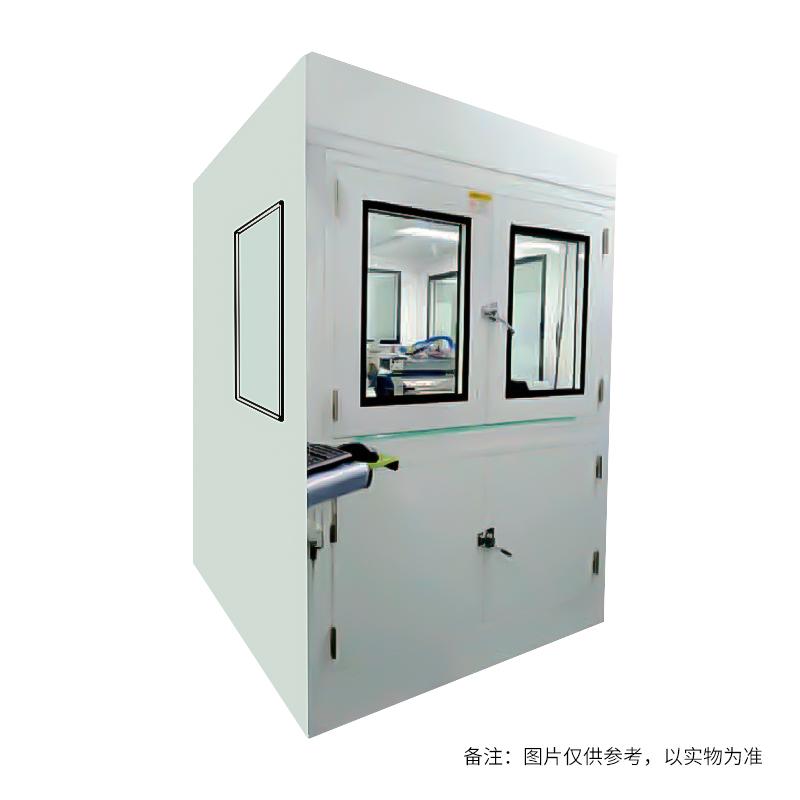

CHINA TBJ-X2-DJ19 Cabinet smart multifunctional Film Applicator Coating size 600 * 1000mm

Customized model, Floor type structure, Bar & drawdown blade vacuum adsorption, Cabinet Film Applicator + Automatic Feeding System + Remote Intelligent Control, The barrel has stirring function, and the effective Spreader area is 600 * 1000mm.

zy

zy-

HuiNuo TM3300/17D drawdown Bar & blade heating vacuum adsorption Coater (floor type) ECA 140 * 120cm

Login -

TQC AB3500 drying time Recorder, automatic Film Applicator

$ 1613.00 -

HuiNuo TM 2200/02 drawdown blade Vacuum adsorption Film Applicator Adjustable bracket height, effective Spreader area 400 * 400mm

$ 7176.00 -

Chinese removable scraper heating vacuum adsorption Automatic Film Applicator TBJ-X5-DJ6 scraper material 316 stainless steel

$ 4334.00 -

China TBJ-B2-DJ16 Floor drawdown Bar & blade Automatic Film Applicator Coating size 800 * 1000mm

$ 10807.00

TBJ-X2-DJ19 Floor Type Wire Rod Scraper Film Coating Machine is a fully automatic coating machine with vacuum adsorption function, with automatic feeding system, coating width 600*1000mm, floor structure design, using wire rod and doctor blade coating method, suitable for film, release paper, paper, plastic film and other film proofing.

Optional

zy TBJ-X2-DJ19 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Accuracy | ±0.05mm |

| Drawdown blade thickness range | 0~10Mm drawdown blade can be lifted |

| Drawdown blade resolution | 0.001mm |

| Drawdown blade reading method | Differential head digital display reading |

| Drawdown blade material | Die steel |

| Mayer Rod Accuracy | ±0.05mm |

| Coating rod specification | 1-571.5Um (1 imported bar as standard, Spreader thickness is determined according to bar model) |

| Bar material | 304 stainless steel |

| Coating size | 600*1000mm |

| Vacuum Area | 600*1000mm |

| Countertop material | aluminum alloy |

| vacuum aperture | Φ1.2mm |

| Vacuum hole spacing | 20*20mm |

| Vacuum pump size | 380*180*280mm |

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Speed regulation Accuracy | 1mm/s |

| speed control | Infinitely variable speed |

| Feeding principle | Air source pressure flows out |

| Feed Sport Mode | Reciprocating linear motion |

| Feeding back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the running speed of the discharge port) |

| Shaft transmission mode | Timer belt |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-equipped) |

| Power Voltage of charging system | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding bucket configuration | Safety valve, pressure regulating valve, pressure gauge, discharge valve |

| Barrel mixing function | magnetic stirring |

| Intelligent program control | Support computer remote setting film speed, application length, film temperature |

| Appearance structure | Floor-to-ceiling Cabinet Film Applicator, Fully Enclosed, Three Doors |

| Appearance material | Aluminum profile frame + aluminum plastic plate |

| Dimension | 800 * 1200 * 1800mm, subject to actual customization |

| Weight | 250Kg, subject to actual customization. |

| Host Power Supply | 220V 50Hz |

| Control Panel | LCD touch panel |

| customizable function | Automatic feeding, air injection system device, UV solid inclusion device |

zy TBJ-X2-DJ19 Automatic Film Applicator Packing list

Film Applicator X1, casting knife X1, imported bar X1, automatic inking system x1, remote Control system x1, vacuum pump x1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- How to Choose a Film Applicator? Film Applicator Principles, Applications and Selection Steps

- Scraping machine selection case: film substrate large size high accuracy scraping solution

- Laboratory Film Applicator for Spreader Chitosan Film

- Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

- Laboratory Small Film Applicator Applied Glue on Wood Board

- Technical Analysis and Comparison of High Temperature Film Applicators

- Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]

- Application Case of Experimental Scraping Machine Coating Polymer on Non-woven Fabric [Video Demonstration]

- Application of SWIRL/spin Film Applicator in the preparation of metal halide perovskite composite films

TBJ-X2-DJ19

TBJ-X2-DJ19