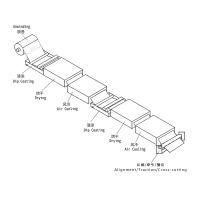

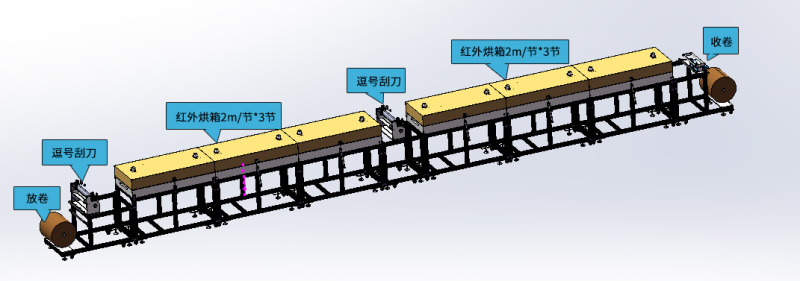

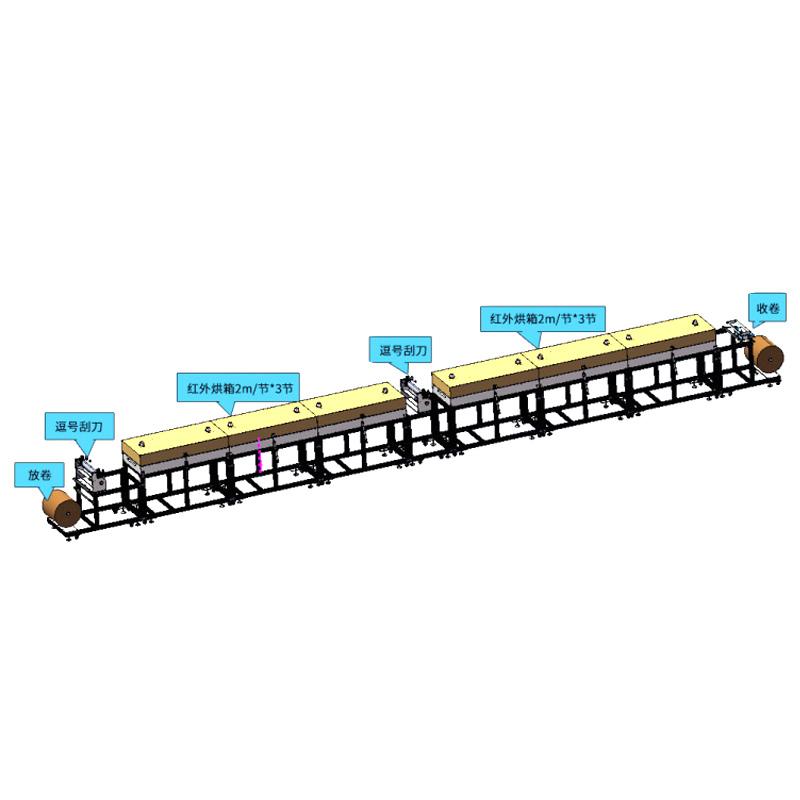

Large coil automatic coating machine, unwinding + comma scraping + infrared drying (6m oven, 2m knots * 3) + comma scraping + infrared Drying Oven (6m oven, 2m knots * 3) + winding

Unwinding + comma scraping + infrared drying (6m oven, 2m sections * 3) + comma scraping + infrared Drying Oven (6m oven, 2m sections * 3) + winding, film width 650mm, rubber roller heating temperature up to 200 ℃.

Factory

Factory-

CHINA Rxf-01/350 pro PET slot die Film Applicator Spreader Width 350mm

$ 47432.00 -

Automatic Film Applicator for large coils unwinding + scraping + drying (8m oven) + heating film laminating + trimming + deviation correction + winding function

$ 28488.00 -

CHINA Micro Coil Automatic Spraying and Coating Machine TBJ-JCPT-DJ1 Customized

$ 19016.00 -

CHINA NBC-DJ5-1500 Automatic Film Applicator 2 meters oven

$ 39539.00 -

CHINA immersion coil drying air-cooled slitting machine Rdc-02/500clcs dip coating machine

$ 39539.00

Introduction

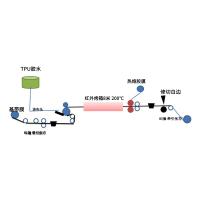

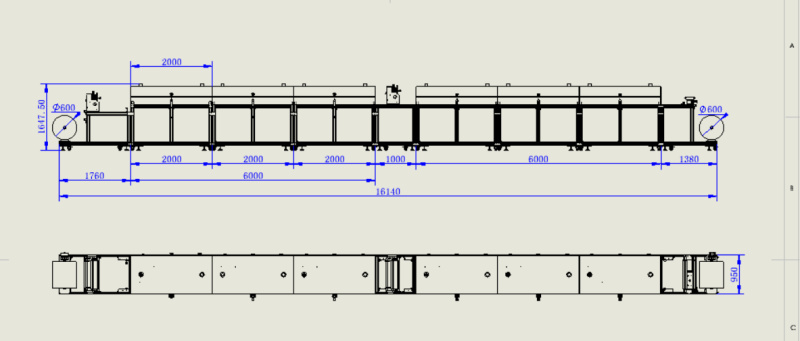

The coating program of RDH-12/650 large coil automatic coating machine is unwinding + comma scraping + infrared drying (6m oven, 2m section *3) + comma scraping + infrared Drying Oven (6m oven, 2m section *3) + winding rubber roller heating temperature up to 200 °C, suitable for hot melt adhesive coating film.

Coating program structure

Factory Rdh-12/650 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating speed | 1~10m/min |

| Effective Spreader Width | 100~650Mm adjustable |

| WFT | 0.005-3mm |

| maximum discharge | 700mm |

| Maximum charge | 700mm |

| Effective Spreader Width | 650mm |

| Drying temperature range | Room temperature -200 ℃ |

| Drying channel length | 10m |

| Total power | 45KW |

| Power Supply | 380V |

| rubber roller | Heating temperature: room temperature~ 200 ℃ |

| Comma drawdown blade | Spreader for adjustable drawdown blade |

| Effective film laminating width | Max.500mm |

| Weight | Subject to actual customization |

| trimming device | √ |

| correction system | √ |

| Traction device | √ |

Factory Rdh-12/650 Automatic Film Applicator Packing list

Host x1, casting knife x2, drying channel x6, correction system x1, correction system x1, rewinding device x1, traction system x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rdh-12/650

Rdh-12/650