Rxg2-03/300cspro pharmaceutical patch special coating machine (double coating head)

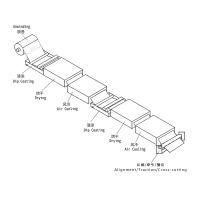

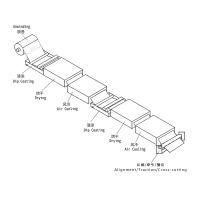

The coating process unwinding → head scraping → drying → tail scraping → return drying → winding → slitting, the effective coating width is Max.φ 300mm, the coating method scraping, the coating rate is 1-10m/min (adjustable), the temperature control accuracy is ± 3 ° C, and the heating method hot air circulation.

Factory

Factory-

Oven coil slot-die Film Applicator Rxf-02/400 Tape unwinding + scraping + drying + overlaying + winding function

$ 31646.00 -

CHINA Automatic immersion coil Coater Rjy-01/500dc double roll extrusion

Login -

Taigang TG - 300-0.5 S laboratory roll-to-roll small Coater desktop roll-to-roll Coater

$ 11912.00 -

Chinese Micro Coil Coating Machine TBJ-JCP-DJ2UV lame plating + scraping with UV curing

$ 28488.00 -

CHINA immersion coil drying air-cooled slitting machine Rdc-02/500clcs dip coating machine

$ 39539.00

Introduction

RXG2-03/300CSPRO coil doctor blade coating machine is a continuous experimental film coating machine with unwinding, scraping, drying and winding functions, the coating film width is 300mm, the wet film thickness is 0.005-3mm, and the heating temperature of the rubber roller is up to 200°C, which is suitable for UV, self-adhesive, plaster, etc.

Product Structure

The machine is composed of a body, a gluing width adjustment device, a discharging rack, a gluing roller group, a thickness adjustment dial gauge, a transmission platform, a traction roller group, and a transmission mechanism.

1. Body: The body of the equipment is composed of aluminum alloy + high static spraying plate.

2. Gluing width adjustment device: The width adjustment device is composed of food-grade plastic and movable brace.

3. Discharging rack: The machine is equipped with two discharging racks, when the two materials are misaligned and deviated in the laminating process, the deviation correction device automatically adjusts the material rack to move left and right to achieve the effect of aligning the two materials.

4. Rubberized roller set: The rubberized roller group is made of double-drum precision machined parts, and the transmission is stable.

6. Thickness adjustment dial gauge: the adjustment of the coating thickness required when gluing. The thickness of the gluing can be adjusted by rotating the left and right handwheels on the gluing roller frame clockwise or counterclockwise, and the specific thickness is determined according to the dial gauge indication.

7. Transmission platform: The transmission platform is made of stainless steel, and its main function is to connect the substrate after gluing to the next process.

8. Traction roller group: the substrate is pulled by hand between the upper and lower rollers of the traction roller, the handwheel on the frame is tightened to make the traction roller, the rubber ring of the upper roller is in contact with the lower roller, and the traction roller group pulls the substrate over through power transmission to complete the coating work.

Features

Substrate tension control, stable belt handling;

The main drive is servo driven, and the speed can be set;

hot Air Oven;

PLC control, HMI operation, convenient and easy to use;

Process Introduction

The equipment adjusts the unwinding tension by controlling the unwinding shaft torque, adjusts the winding tension by controlling the winding shaft torque, and realizes the belt transport control with the rotation linear speed of the main drive steel roller as the main driving speed.

The Drying Oven uses electrically heated air, and the hot air heats and dries the substrate.

Factory Rxg2-03/300cspro Special coating machine for pharmaceutical patches (double coating heads)Specifications

| LIST | VALUE |

|---|---|

| Spreader process | Unroll → head scraping → drying → tail scraping → return drying → winding → slitting |

| Effective application width | Max.Φ300mm |

| Coating method | scraping |

| Cutting head type | Drawdown blade adjustable |

| Display mode indication | digital display |

| WFT | 0.005-3mm |

| Regulator Graduation | 0.001mm |

| Spreader Accuracy | ±3% |

| Coating speed | 1-10M/min (adjustable) |

| unwinding method | Inflatable shaft unwinding |

| winding method | Inflatable shaft winding |

| Outer diameter of winding air expansion shaft | 3-Inch expansion shaft, load-bearing 50KG |

| maximum discharge | Max.Φ300mm |

| maximum charge | Max.Φ300mm |

| Drying Temperature range | RT+~200℃ |

| Temperature control Accuracy | ±3℃ |

| Heating mode | hot air circulation |

| Oven length | 1M/section * 3 sections |

| Total length of drying tunnel | 3m |

| Drying Power | 1KW/section |

| Motor type | step |

| Control mode | PLC + touch screen |

| Human Machine Interface | Color touch screen |

| tension control | automatic |

| Correction control | automatic |

| thickness control | manual |

| Roller material | Teflon non-stick roller |

| Slitting method | Hob slitting |

| split into sizes | According to customer customization requirements |

| Slitting speed | Synchronize with the production line |

| gas source | 0.5~ 0.8MPa compressed air |

| Applicable coil type | Plastic film, metal foil, paper, non-woven fabric, etc |

| Spreader type | Water-based paints, solar-based paints, UV coatings, etc |

| Environmental temperature | 10℃ ~ 40℃ |

| Environmental humidity | 30~90%RH |

| power requirements | 380V, 50Hz, three-phase five-wire system |

| Total power consumption | 3KW (subject to actual customization) |

| Dimension | About 6000mm * 500mm * 1600mm (subject to actual customization) |

| Weight | 1t (subject to actual customization) |

Factory Rxg2-03/300cspro Special coating machine for pharmaceutical patches (double coating heads) Packing list

host x1, scraper x2, slitting hob x1, manual x1, packaging list x1, certificate of conformity x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rxg2-03/300cspro

Rxg2-03/300cspro