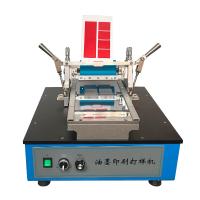

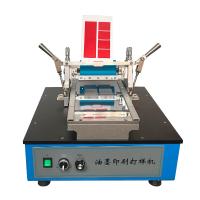

JINGGONG CP168 Ink Proofer shade test

Using the same speed and pressure parameters as the printing press, the printing speed is 0~260m/min, and the Accuracy Delta value is less than 0.5. It supports fast color development and detection of various inks characteristics, and the operation is simple and efficient.

DeJingGong

DeJingGong-

HUINUO intelligent CP225-A inks color display instrument, plastic printing proofing machine

$ 5124.00 -

MODERNER Rubber roller inks printing proofing machine accessories

Login -

YINUO YN-ZSY-4 offset plate inks spot color Proofer inks color display instrument, offset printing four-color offset plate printing two-color optional

$ 4429.00 -

HuiNuo HN-AY80 Gravure Ink Proofer color scheme Special numerical control LCD display

$ 3040.00 -

HuiNuo CP150 gravure plate Proofer Gravure ink printing machine printability instrument

$ 4018.00

Fields of application

Applicable plate making companies

(1) Instead of manual ink scraping, under the same parameters as the speed and pressure of the printing machine, the spot color can be quickly and accurately debugged, which greatly reduces the number and time of proofing of the concave prototype.

2. The company's production process curve is simple and convenient, and the process personnel can quickly display the color separately without the cooperation of the concave sample workshop.

(3) The manuscript designer can also show the color to the on-site customer within 5 minutes, and the customer can see the final printed color on the finished product at the beginning of the design.

Applicable printing companies

(1) Instead of manual ink scraping, under the same parameters as the speed and pressure of the printing machine, the spot color can be quickly and accurately debugged, which greatly reduces the waste of ink mixing on the high-speed printing machine.

2) The color spreader can greatly reduce the residual ink inventory of the printing company with the cooperation of Colorimeter and color software.

Applicable to oil waste ink manufacturing companies

(1) Data management, with spectrometer for color inspection, measurement of color bar data report.

2) Cooperate with relevant instruments to test the wear resistance, color fading, transferability, light and heat resistance and other characteristics of the ink

DeJingGong CP168 Gravure Ink ProoferSpecifications

| LIST | VALUE |

|---|---|

| Maximum printing width | 110Mm (can be customized) * 365mm |

| printing speed | 0~260m/min |

| Accuracy | The value is less than 0.5. |

| control Voltage | 24V DC |

| input Voltage | AC 220V |

| Power | 0.5KW |

| Machine size | 630*550*550mm |

| Machine Weight | 105Kg |

DeJingGong CP168 Gravure Ink Proofer Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

CP168

CP168