MODERNER JZ-200 Non-Interventional Material Homogenizer 350ml × 1

The container capacity is 350ml × 1, and the maximum processing capacity is 175ml × 1/250g × 1. It supports single-parameter (stirring mode) and multi-parameter (multi-segment mode) operations, and can store 8 sets of formulas. The revolution and rotation synthesis force can achieve homogeneous mixing and efficient defoaming.

Moderner

Moderner-

Huxi FJ300-SH Digital Display Constant Speed High Speed Dispersion Homogenizer Φ28/36mm

$ 605.00 -

Huxi HX-4GM beat homogenizer, upgraded model

$ 1161.00 -

Lanyu 24G Homogenizer can be equipped with optional dispersion head

$ 443.00 -

Huxi FJ200-SH Digital Display Constant Speed High Speed Dispersion Homogenizer Φ12/18mm

$ 585.00 -

RONGHUA RHJZQ-10 Pat Aseptic Homogenizer

$ 798.00

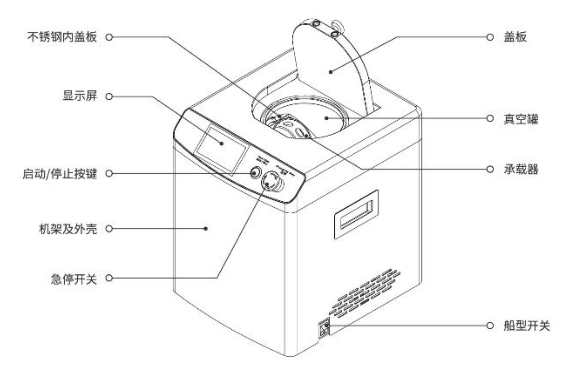

Introduction

JZ-200 Homogenizer is a high-efficiency equipment specializing in mixing, homogenizing and deaeration of high-viscosity materials, with a non-intrusive design, through the combined movement of revolution (200-2000 RPM) and rotation to generate strong centrifugal force, ensure that the material is fully mixed and quickly degassed, while reducing the temperature rise and protecting the material properties. The equipment is equipped with a touch screen operation interface, supports 8 groups of recipe storage, provides two operation modes of single parameter (stirring mode) and multi-stage parameter (multi-stage mode), and has multiple protection functions such as emergency stop, vibration detection, door cover safety lock, etc., and is suitable for precision processing in the fields of adhesives, pastes, electronic packaging materials, etc.

Operating Principle

Driven by a single motor, the carrier is able to perform both high-speed revolution (rotation around the central axis) and rotation movement. The strong centrifugal force generated by the revolution causes the material to move in the vector direction and extrude downward, while the rotation creates a vortex stirring effect, and the combined force of the two movements makes the material fully homogeneous. In this process, centrifugal force rapidly presses the bubbles inside the material to the surface and bursts, achieving efficient degassing. The design optimizes the handling of high-viscosity materials, ensuring the mixing effect while effectively controlling the temperature rise and avoiding damage to the material properties.

Features

Single and double cups

Vacuum optional

The rotational speed ratio is constant

Multi-segment parameter settings

There is a wide variety of adapters

It has a wide range of applications, can be developed and mass-produced

Series selection

| Device model | JZ-200 | JZ-350S | JZ-700S |

| Container capacity | 350ml×1 | 350ml×2 | 700ml×2 |

| Maximum processing capacity | 175ml ×1 / 250g×1 | 175ml ×1/ 250g×2 | 350ml ×2 / 500g×1 |

| Operating Principle | standard | ||

| Recipe storage | 8 groups | ||

| Revolutional speed | 200-2000 RPM | ||

| Rotation scale | Fixed ratio | ||

| Dimensions (mm) | L380×W420×H430 | L380×W420×H430 | L430×W470×H650 |

| Weight (kg) | 35 | 35 | 60 |

| Voltage, power | 220V,0.4KW | 220V,0.4KW | 220V,1KW |

| Screen type | Serial screen | ||

| vacuum | External, optional | ||

| Refrigeration fixtures | Optional | ||

| Standard fixtures | Optional | ||

Moderner JZ-200 HomogenizerSpecifications

| LIST | VALUE |

|---|---|

| container Capacity | 350ml×1 |

| Maximum processing Capacity | 175ml ×1/250g×1 |

| Operation mode | standard |

| formula storage | 8 groups |

| Rotation speed | 200-2000RPM |

| Rotation ratio | fixed ratio |

| Size (mm) | L380×W420×H430 |

| Weight (kg) | 35 |

| Voltage, Power | 220V,0.4KW |

| Screen type | Serial screen |

| vacuum | External, optional |

| Refrigeration jig | Optional |

| Standard fixture | Optional |

Moderner JZ-200 Homogenizer Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

JZ-200

JZ-200