Factory Direct Rgdc-0.5/200 immersion coil Coater (with drying) effective width 200mm

Spreader process unwinding → soaking → double roll extrusion residual material → drying → winding, Coating size ≤ 200mm, guide roller width 200mm, drying tunnel temperature adjustable at room temperature~ 100 ° C, extrusion unit extrusion method → double roll extrusion, Coating speed adjustable from 0~20m/min

Factory

Factory-

NBC-SNJ500 touch screen hydrogel Coater with slitting

Login -

HuiNuo JTM - 0.5/300 UV roll-to-roll test coater Continuous Film Applicator with heating UV curing

$ 9860.00 -

Factory Direct Rgdc- 01.2/400 immersion coil Coater application width 400mm

$ 23752.00 -

Pilot-scale coil automatic film laminating machine, with unwinding + scraping + drying + film laminating + deviation correction + winding function application width 750mm

$ 23752.00 -

CHINA Rjy-01/200dc Immersion Crystallization Coater Continuous Film Applicator

$ 47432.00

Introduction

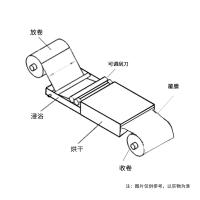

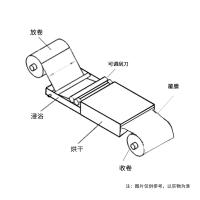

RGDC-0.5/200 immersion coil coating machine (with drying) is a factory direct product, with an effective width of 200mm, specially designed for plastic film, paper, non-woven fabrics and other coils, which can be used for dipping water-based coatings, solvent-based coatings, UV coatings, etc., and complete the drying process simultaneously, which is suitable for the coating needs of a variety of industrial production scenarios.

Features

Efficient process - "unwinding→immersion bath→ double-roll extrusion of remaining materials→ drying →winding" process, dipping and drying are integrated, and the production is consistent and efficient.

Precise control - the drying channel temperature can be adjusted at room temperature -100°C, the coating rate is controllable from 0 to 20m/min, the double roller extrusion gap is 1 - 10mm, the handwheel is adjusted with the dial gauge display, the tension and deviation correction are automatically controlled, and the deviation correction accuracy is ±1mm.

Widely applicable - support a variety of coils and coating fluids, the immersion bath is made of corrosion-resistant stainless steel, suitable for different solution characteristics.

Stable and reliable - scientific structural design, reasonable rewinding and unwinding diameter and load-bearing, air source and power supply to meet conventional needs, to ensure the stable operation of the equipment.

Factory Rgdc-0.5/200 Soaking coil coater (with drying)Specifications

| LIST | VALUE |

|---|---|

| Spreader process | Unwinding → soaking → double roll extrusion residue → drying → winding |

| Coating method | dip coating |

| Coating size | ≤200mm |

| Width of guide roller | 200mm |

| Bath size | 200Mm width * 500mm length * 500mm height mm |

| Drying tunnel size | 200Mm width * 500mm length * 500mm height mm |

| Drying tunnel temperature | Room temperature~ 100 ℃ adjustable |

| Extrusion unit | Extrusion method → double roll extrusion |

| Squeeze adjustment display | Handwheel adjustment, dial indicator display |

| Squeeze adjustment gap | 1-10mm |

| Coating speed | 0~20M/min adjustable |

| winding diameter | 3-Inch expansion shaft, load-bearing 50KG |

| tension control | Max.60N |

| unwinding diameter | Max. Ф200mm |

| winding diameter | Max. Ф200mm |

| Tension control mode | automatic |

| Deviation Correction control mode | automatic |

| Correction Accuracy | ±1mm |

| Dip coating type | Solution soaking (Note: After the substrate is crystallized in solution, it can be rolled around the tape) |

| Dip coating material | Corrosion-resistant stainless steel (note that the solution cannot chemically react with the material) |

| Number of baths | 1 |

| Applicable coil type | Plastic film, paper, non-woven fabric, etc |

| Spreader type | Water-based paints, solar-based paints, UV coatings, etc |

| Dimensions | 4000Mm * 600mm * 1600mm (subject to actual customization) |

| Weight | 0.5T (subject to actual customization) |

| Power Supply | Single-phase AC220V +/- 10%, frequency 50Hz, power 9.5KW |

| gas source | 0.5~ 0.8MPa compressed air |

Factory Rgdc-0.5/200 Soaking coil coater (with drying) Packing list

Whole machine x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rgdc-0.5/200

Rgdc-0.5/200