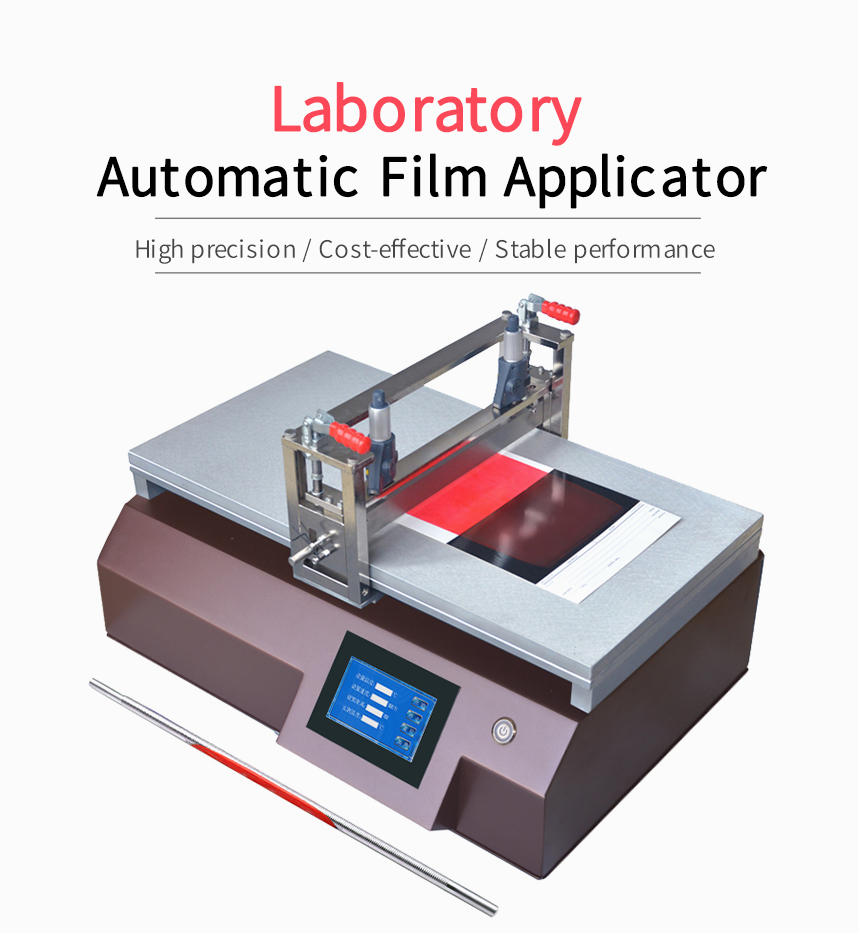

China TBJ-B2-DJ16 drawdown Bar & blade UV curing Automatic Film Applicator with automatic feeding system

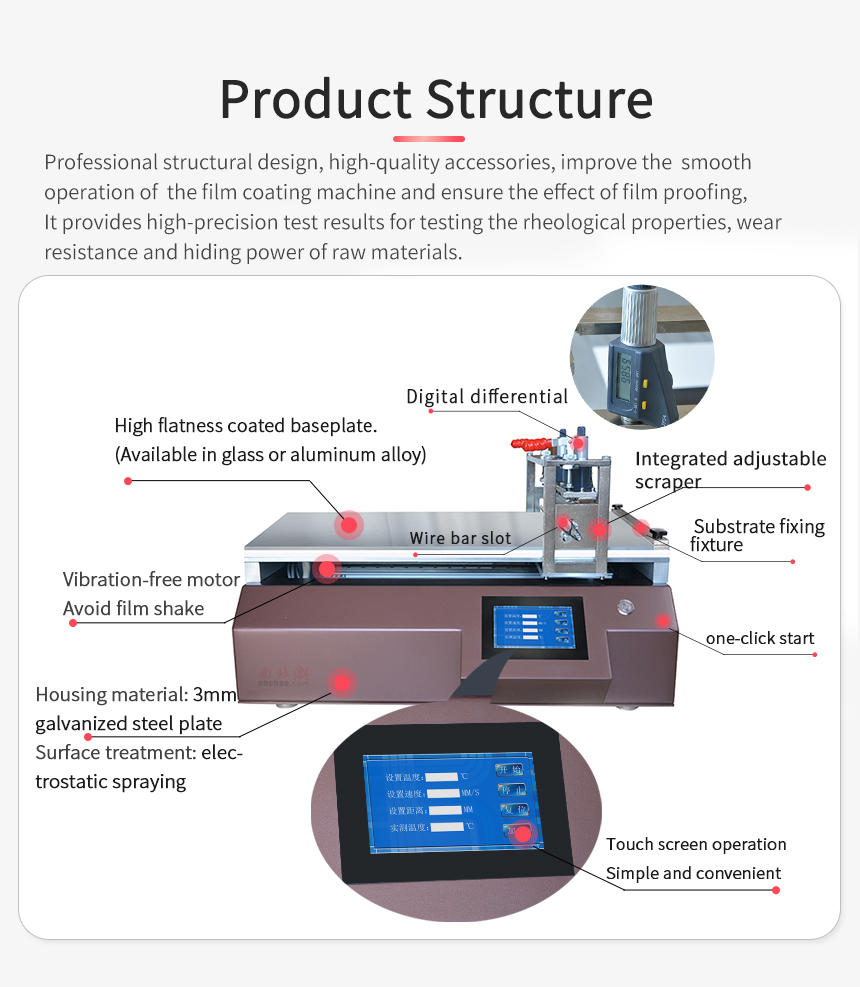

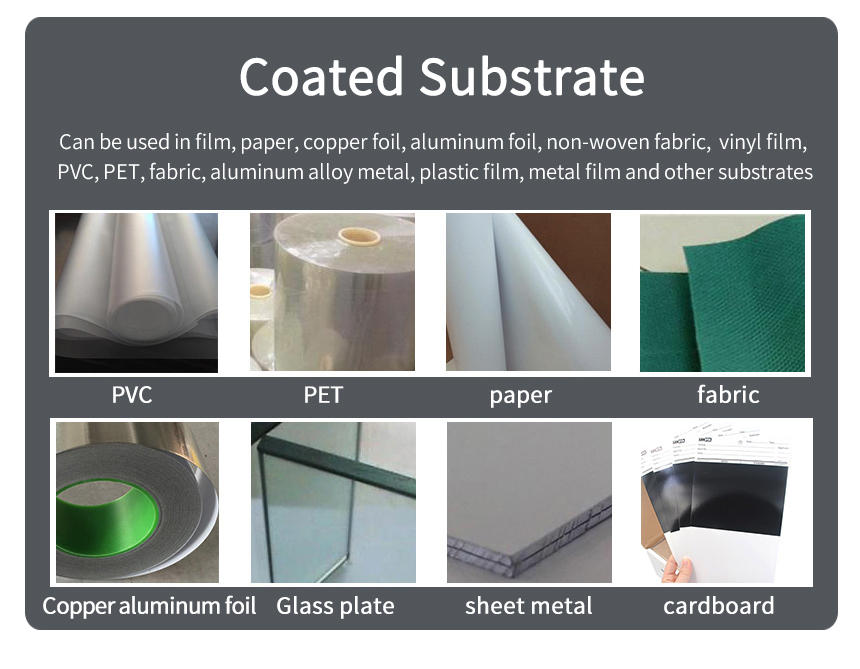

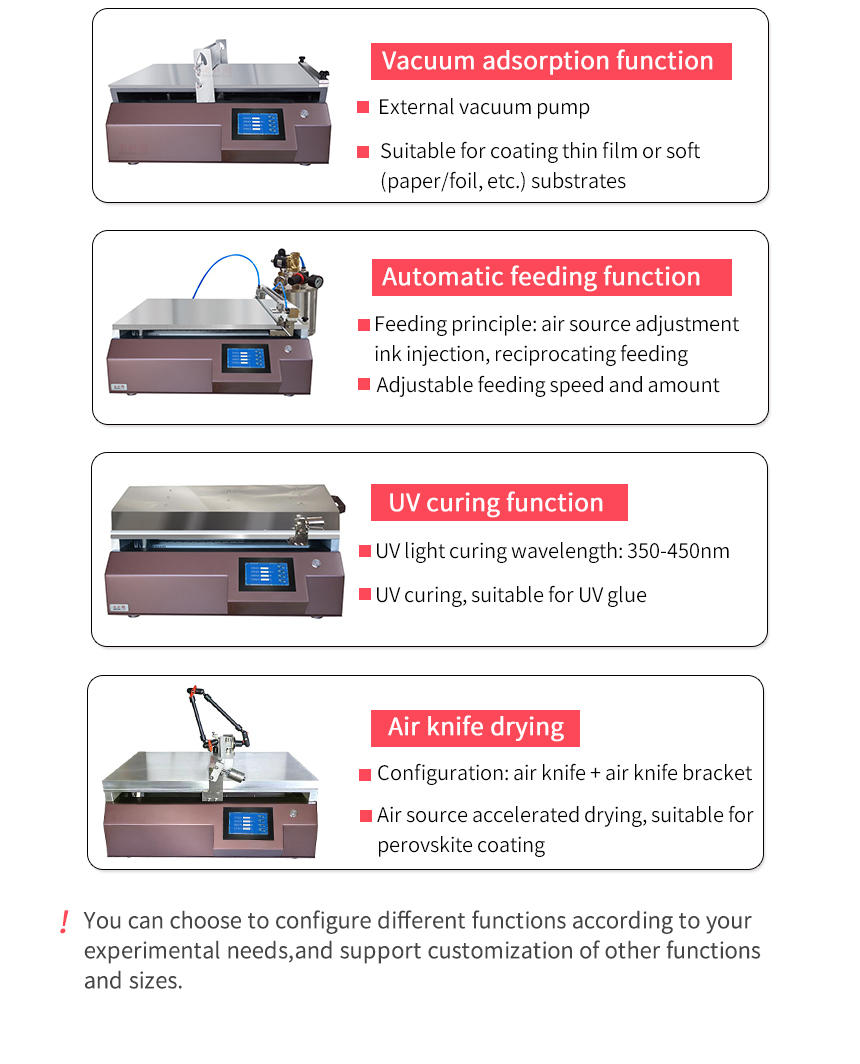

Adjustable Drawdown blade + bar two coating methods, with UV ultraviolet curing function, with automatic feeding system, Glass baseplate size 300 * 400mm, digital touch screen control, effective coating format 300 * 400mm.

zy

zy-

HuiNuo TM1300Pro/01D Floor type bar heating Vacuum chuck Coater 100 * 90cm

Login -

HuiNuo TM3300proAF/03 Automatic Film Applicator bar drawdown blade Coater ECA 60 * 40cm

$ 7807.00 -

HuiNuo TM3300/07 Multifunctional miniature Coater (for glove box) Spreader area 21 * 15cm

$ 5124.00 -

HuiNuo TM3300Pro/18D drawdown Bar & blade heating vacuum adsorption Coater (floor type) servo motor

Login -

HuiNuo TM3200Pro/04 drawdown Bar & blade Vacuum chuck Coater ECA 70cm * 60cm

Login

Optional

zy TBJ-B2-DJ16 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Spreader Accuracy | ±0.003mm |

| Drawdown blade Spreader Film thickness range | 0.01~10mm |

| Coating Speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Effective coating Area | 400*300mm |

| Meyer rod coating thickness Range | 1~ 571.5 μm (Spreader Film thickness according to bar type) |

| Meyer rod coating Accuracy | ±0.001mm |

| Drawdown blade material | 304 stainless steel |

| Host Power Supply | 220V 50Hz 1700W |

| Dimensions | 626*410*520mm |

| Weight | Subject to the actual product |

| speed control | Infinitely variable speed |

| Bottom plate material | Glass |

| Spreader Itinerary | Digital arbitrary setting within the range of 1~ 400mm |

| UV curing area | 400*300mm |

| UV light main peak wave | 36nm |

| UV light power | 400*2W |

| UV light curing wavelength | 350~450nm |

| switch | Aviation plug/separate switch |

| Light source spacing | 18*18mm |

| Lamp board height from coating table | 20Mm (support customized adjustable height) |

| Shaft transmission mode | Timer belt |

| Ink-jet principle | Air pump |

| Sport mode | Reciprocating linear motion (single ink) |

| Back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the operating speed of the discharge port) |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-equipped) |

| Feeding system power Voltage | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding bucket configuration | Safety valve, pressure regulating valve, pressure gauge, discharge valve |

| Feeding drum Volume | 1L |

| Coating Method | Bar + drawdown blade |

zy TBJ-B2-DJ16 Automatic Film Applicator Packing list

Film Applicator x1, bar x1, Drawdown blade x1, UV curing device x1, automatic feeding system x1, manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

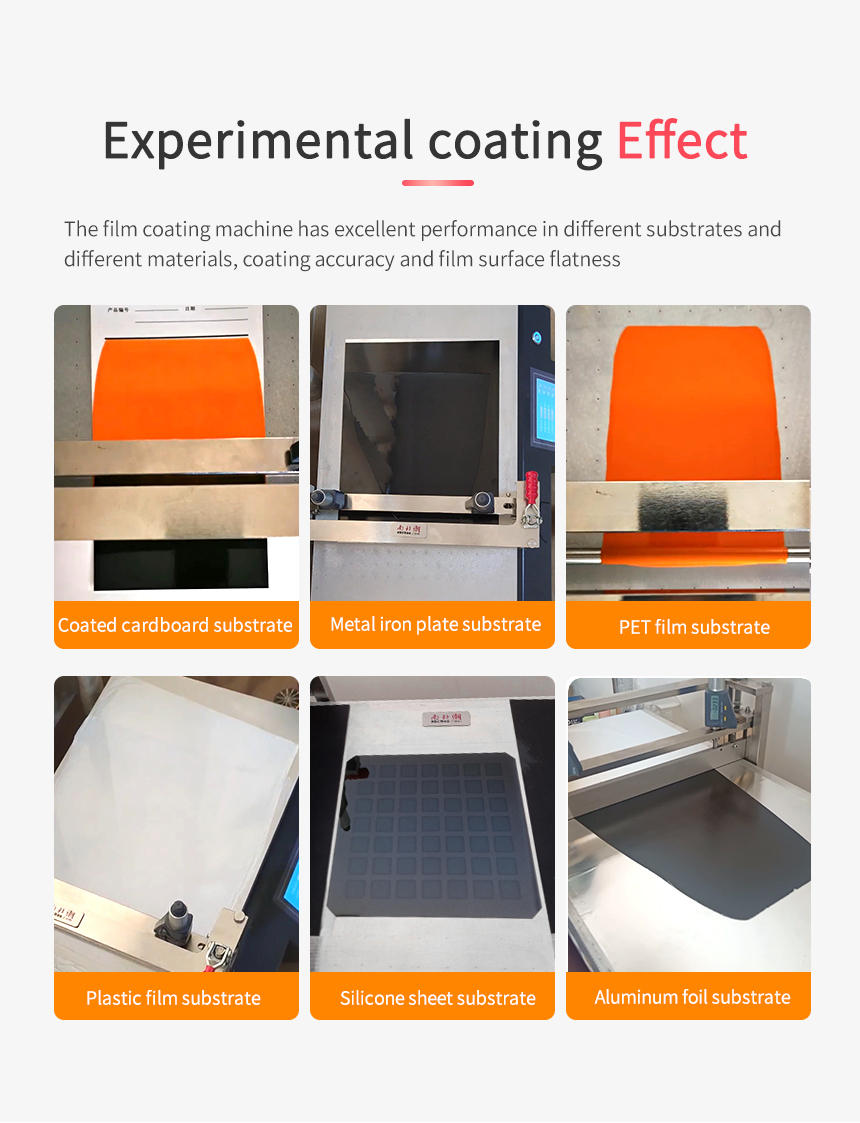

- Study on Experimental Technique of Automatic Film Applicator for Filtered Glass

- Application Case of Automatic Film Applicator Coating Metal Powder Solution on Titanium Fiber Felt [With Video]

- Application of Automatic Film Applicator in Phosphor Coating

- Experimental Application of Automatic Film Applicator on Glass substrates

- Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- Application of Experimental Automatic Film Applicator in photoresist film prepative

- Experimental Application of Automatic Film Applicator for Coating Hot-melt adhesive on Breathable Film

- Automatic Film Applicator Application of UV Adhesive on Silicon Wafer [Video Demonstration]

- Pressure sensitive adhesive on PET film by Automatic Film Applicator

- Application of Automatic Film Applicator on BOPP Thin

TBJ-B2-DJ16

TBJ-B2-DJ16

TBJ-B2-DJ4

TBJ-B2-DJ4