JINGKELIAN QXD (0-50um cr12 molybdenum vanadium) Grindometer Fineness gauge 0~50μm/5μm

JINGKELIAN QXD0-50um Grindometer material is cr12 molybdenum vanadium, is a single-channe Fineness gauge, in line with GB1724 standard, QXD Grindometer fineness range 0-50um, Graduation of 5.0 microns.

JingKeLian

JingKeLian-

TQC VF2122 wide-channel Grindometer 0~50μm with calibrated certificate

$ 1245.00 -

TRUIT TR 1202/150 double-channel Fineness gauge 0~150μm

$ 190.00 -

TRUIT TR 1201/025 single-channe Fineness gauge 0~25μm

$ 168.00 -

Pushen QXD-25um single-channe Fineness gauge 0-25μm

$ 163.00 -

MODERNER QXD-100 single-channe Fineness meter, corrosion-resistant stainless steel 0~100μm range

Login

Introduction

This Fineness Meter is designed according to the standard coating inspection method issued by the Ministry of Chemical Industry: Fineness meter determination method GB1724-79. It can be used to test the fineness of pigments, fillers and impurities in paints and paint slurries, expressed in microns. .

Purpose: Determine the particle size of fuel filling and impurities in paints, paint slurries and inks

Instructions

When using, first wash the scraper and scraper with gasoline, wipe them dry with cotton gauze, and then wipe them with deerskin. Dip a glass rod into a small amount of the paint to be measured that has been mixed (consistency consistent with the product standard) and drip it onto the scraper at an angle. In the deepest part of the groove, the amount of dripping should be slightly more than the appropriate amount to fill the chute. Then use the thumb, index finger and middle finger of both hands to place the scraper horizontally on the top of the scraper, so that the edge of the scraper vertically contacts the surface of the scraper. From the depth of the chute, Pull it towards the shallow place and immediately (within 5 seconds) observe the scale line where the particles in the tank are evenly exposed. This value is the fineness of the pigment and other particles in the paint.

other

1. The surface of the scraper and the edge of the scraper must not be bumped.

2. Wash and apply anti-corrosion oil after use.

3. Check the scraper regularly every year to check the flatness of the blade. If it does not meet the requirements, it should be repaired.

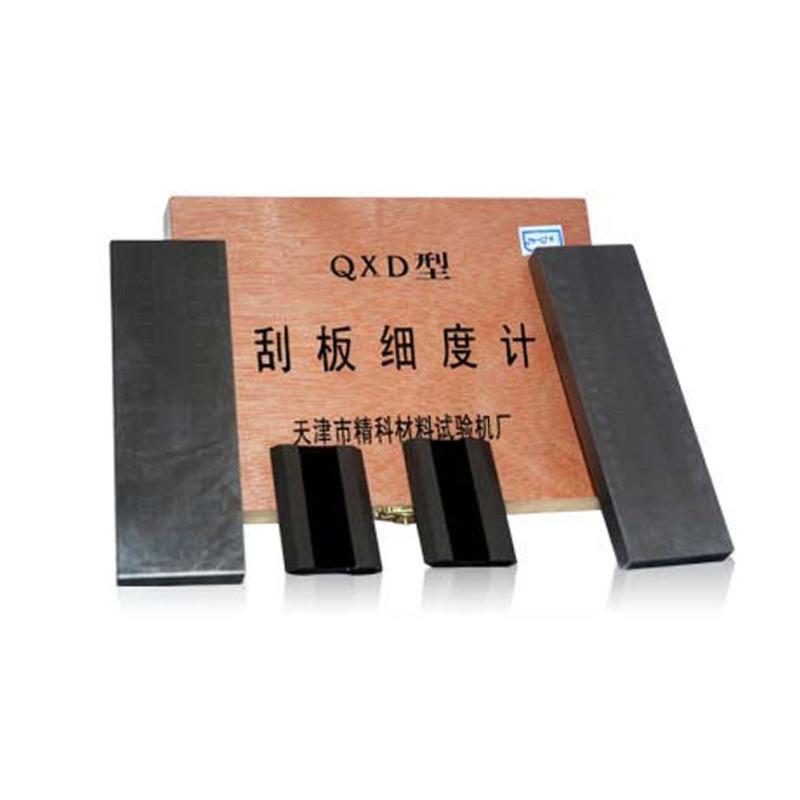

4. This instrument has one built-in scraper and two scrapers per box.

5. This instrument is suitable for use at a temperature of 22±1℃ and a Relative Humidity of 70% to ensure accuracy.

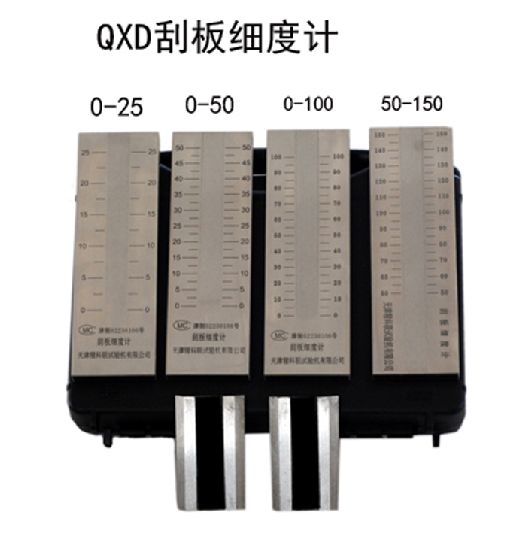

Product picture display

JingKeLian QXD 0-50 (cr12 molybdenum vanadium) Fineness of Grind GaugeSpecifications

| LIST | VALUE |

|---|---|

| Scraper type | Single-channe |

| Number of grooves | 1 |

| range | 0~50μm |

| Scale unit | μm |

| Graduation | 5.0μm |

| scraper material | CR12 Molybdenum Vanadium |

| Scraper size | 155*50*12mm |

| Groove size | 13*120mm |

| Drawdown blade size | 68*40*6.5mm |

| Applicable standards | GB1724-79 |

| Surface finish on scraper | 10 |

| Chute bottom surface finish | 8 |

| Drawdown blade two knife edge finish | 8 |

| Drawdown blade two knife edge plane flatness | 0.002mm |

| Flat flatness on scraper | 0.003mm |

| Plane flatness of chute bottom | 0.003mm |

JingKeLian QXD 0-50 (cr12 molybdenum vanadium) Fineness of Grind Gauge Packing list

Scraper x1, doctor blade x2

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- AbolishTB/T 2260-1991

- ActiveHG/T 5370-2018

- ActiveHG/T 5367.1-2018

- ActiveHG/T 5183-2017

- ActiveHG/T 5180-2017

- ActiveHG/T 5175-2017

- ActiveASTM D1316-2020

- ActiveGB/T 5211.17-1988

- ActiveASTM D333-2021

- AbolishGB/T 13217.3-2008

- ActiveHG/T 2243-1991

- ActiveGB/T 13492-1992

- ActiveGB/T 17459-1998

QXD 0-50 (cr12 molybdenum vanadium)

QXD 0-50 (cr12 molybdenum vanadium)