Factory Direct Rjy-00/1000 immersion type Coater dip coating double roll extrusion equipment, effective width 1000mm

Using immersion coating method, equipped with built-in circulation system, Spreader thickness 0.3-10 mm adjustable, mechanical speed 0.1-1 m/min adjustable, double roll extrusion to ensure uniform Spreader.

Factory

Factory-

CHINA NBC-DJ4-JPJC-200 Immersion crystallization Coater Roll-to-Roll Film Applicator

$ 47432.00 -

HuiNuo JTM-300 Small continuous Coater Roll-to-roll Film Applicator No air source required

$ 5597.00 -

Factory direct sales Rgdjy-02/350dcpro immersion coil Automatic Film Applicator wet film thickness 0.005-3mm Continuous experimental Automatic Film Applicator

$ 28488.00 -

Chinese Micro Coil Coating Machine TBJ-JCP-DJ2UV lame plating + scraping with UV curing

$ 28488.00 -

Factory Direct Rgdc- 01.2/400 immersion coil Coater application width 400mm

$ 23752.00

This machine is mainly suitable for coating (immersion bath) production winding equipment for roll substrates

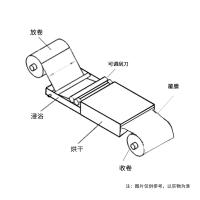

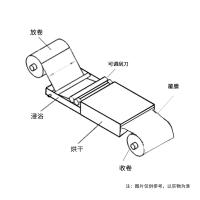

Equipment process

Unwinding→ dipping (built-in glue circulation system) → double roller extrusion → pull-out load-bearing platform (1 meter)

Main part configuration

(1) Unwinding unit (1 set in total)

Structural features:

Type: Single station

Effective unwinding width: 1000mm

Effective unwinding diameter: ≤φ400mm

Unwinding shaft: 3" (Φ76mm) inflatable shaft 1 piece (suspended wall structure)

Unwinding tension control: automatic tension control, magnetic particle brake, tension controller

Specifications:

Main configuration of unwinding:

Magnetic powder brake:

Tension Controller:

Inflatable shaft: 3"/cantilever (winding part)

(2) Front traction unit

Structural features::

1. Double roller roller structure, rigid and flexible combination

2. Steel roller: Φ42x800mm, surface plated with hard chrome, super fine grinding;

3. Rubber roller: Φ60x800mm: Shaw (A) 70~75°, silicone material, pneumatic solenoid valve control adjustment, pressureadjustable(No need to install rubber rollers)

Specifications

Main traction configurations:

Steel roller: Φ42x800mm

Motor: SEND/0.75KW (Servo Control)

Factory Rjy-00/1000 Soaking coil coaterSpecifications

| LIST | VALUE |

|---|---|

| Spreader process | Unwinding → dip coating → double roll extrusion → winding |

| main substrate | PET or other non-breakable materials |

| glue | Water-based paints, solar-based paints and Miscellaneous |

| Spreader thickness range | Adjustable according to the process (formed) |

| Coating Method | soak |

| Bath size | 1500Mm length * 1000mm width * 300mm depth (built-in circulation system, can be exchanged with external solvents to filtrate) |

| Bath material | Resistant corrosion stainless steel (note, the solution cannot react chemically with the material) |

| Dip tank guide roller | 2 sticks |

| Effective application width | Max.1000mm |

| substrate | Less than 1000mm |

| Roll surface width | 1000mm |

| Extrusion unit - extrusion method | Double roll extrusion |

| Extrusion Unit - Adjustable Range | 0.3-10mm |

| Extrusion Unit - Spreader Adjustment | Handwheel adjustment, dial indicator display |

| Mechanical speed | 1.2M/min (0.1~ 1m/min production speed, depending on the process) The speed can be adjusted slowly |

| unwinding diameter | ≤ φ 400mm (paper core 3 ") |

| winding diameter | ≤ φ 500mm (paper core 3 ") |

| Reel the edges neatly | ±3.0mm |

| Total Installed Power | About 5kW (subject to actual customization) |

| Machine size | (L x W x H) According to process changes and final design drawings |

| Teflon roller | 4 pieces (installed in front of the Spreader head) |

| Power supply Voltage | Three-phase five-wire 380V 50Hz |

| Unwinding Unit - Type | Single station |

| Effective unroll width | 1000mm |

| Effective unwinding diameter | ≤Φ400mm |

| Unwinding Unit - Unwinding Scroll | 3 " (φ 76mm) 1 piece of inflatable shaft (suspended wall structure) |

| Unwinding Unit - Unwinding Tension Control | Automatic tension control, magnetic particle brake, tension Controller |

| Front Traction Unit - Steel Roller | Φ42x1000mm |

| Front Traction Unit - Motor | SEND/0.75KW (servo control) |

| conclusion | 1 meter bearing platform |

| size | About L5000mm x W1300mm x H1500mm (Note: subject to actual customization) |

| Weight | About 1t (subject to actual customization) |

Factory Rjy-00/1000 Soaking coil coater Packing list

machine x1, manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rjy-00/1000

Rjy-00/1000