HuiNuo JTM-300 Small continuous Coater Roll-to-roll Film Applicator No air source required

High-precision modular Spreader station structure, no air source, minimum gluing thickness 0.01mm, can be separated from the winding module, with quick-release plastic tank and electronic precision tension control function.

HuiNuo

HuiNuo-

NBC-ZYTJ300 special Coater Spreader compound slitting integration

$ 19016.00 -

Chinese Micro Coil Coating Machine TBJ-JCP-DJ2UV lame plating + scraping with UV curing

$ 28488.00 -

Factory Outlet Rgd - 0.5/300 S Desktop Roll-to-Roll Film Applicator

$ 9228.00 -

Taigang Rgd-300TS Double-sided Coil Film Applicator Guide Roller Width 300mm oven length 1m

$ 39539.00 -

NBC-SNJ500 touch screen hydrogel Coater with slitting

Login

Introduction

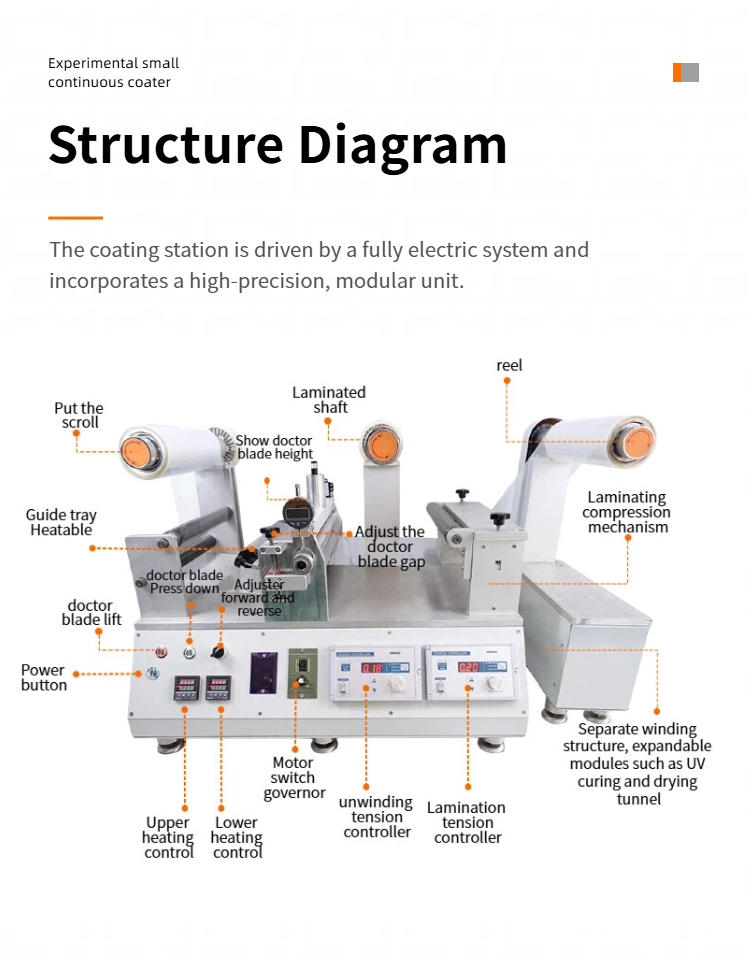

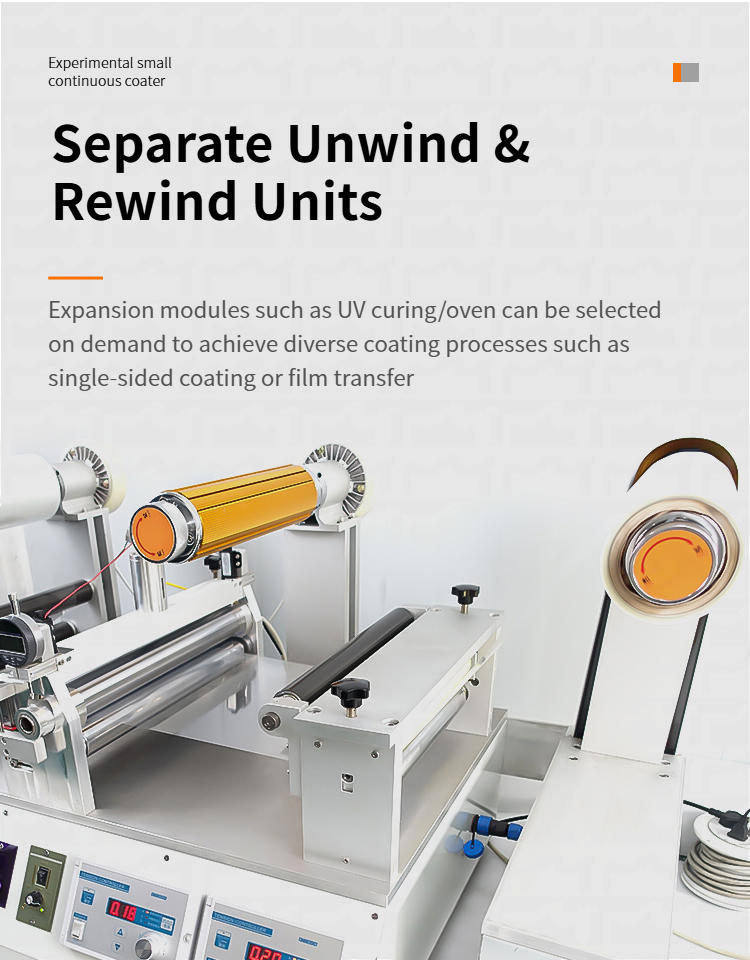

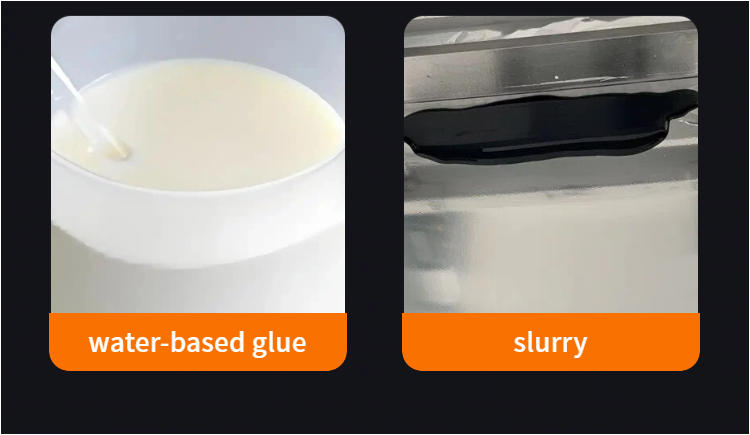

The continuous hot melt adhesive coating experimental machine is a modular assembly of high-precision modular coating station mechanism, with a separable winding module, which can be added as needed, and the whole machine is fully electrically controlled, without the need for an external air source. Continuous coating proofing or low-volume production of laboratory mini hot melt adhesive coaters. The hot melt pressure-sensitive adhesive can be directly applied to the heat-resistant substrate, or coated on the release paper and then the film transfer map can be applied to different surface materials, or the single-sided coating film of the curing module can also be added. Electronically controlled precision tension control, which can adapt to the needs of different materials. Such as paper, plastic model, metal film, etc.

Configuration brief

(1) The whole machine is a high-precision modular coating station structure, which adopts modular assembly.

(2) Fully electric control, no external air supply required

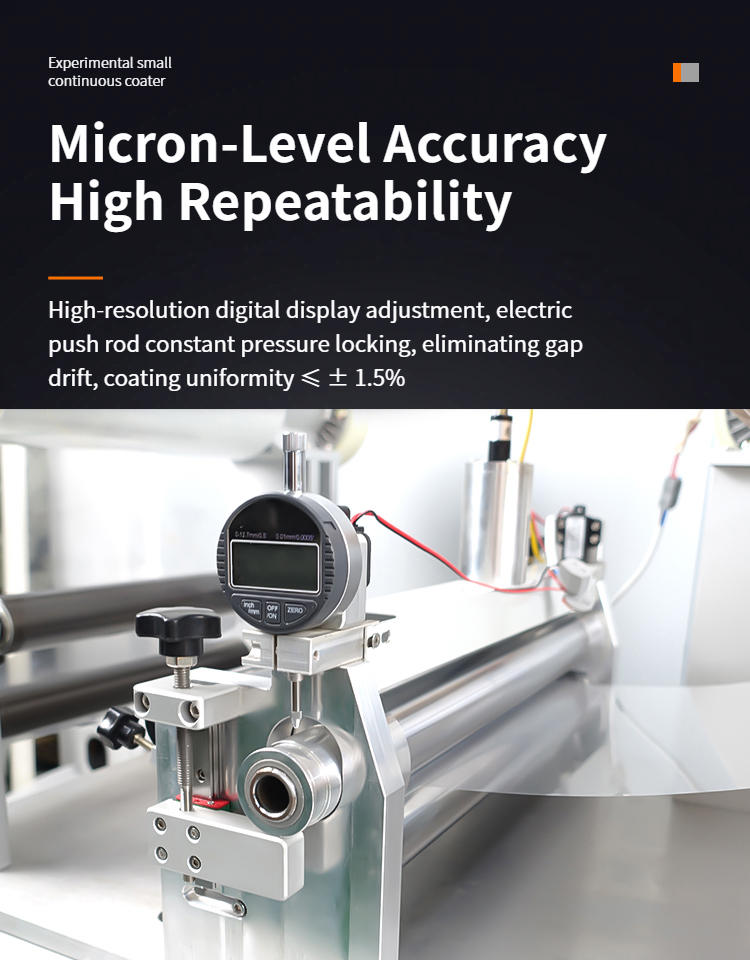

(3) Use the dial indicator as the index head to accurately fine-tune the coating gap between the upper and lower rubber wheels to control the coating thickness.

(4) The minimum gluing thickness is0.01mm。 After the thickness is set, the downforce is provided by the electric actuator to prevent the gap from changing

(5) The maximum coating width is 300mm (effective coating width is 280mm). The width is adjusted by two pieces of PEEK baffles in the rubber groove. It can be coated and glued for unlimited length, and is automatically rewound.

(6) Forward and reverse stepless variable speed, coating speed: 4.5m/min (speed 2-4.5m/min adjustable), precision electronically controlled discharge reel can adjust the knob of the control panel, accurately change the discharge tension, and keep it continuously.

(7) Quick-release glue tank, the glue wheel and the rubber groove can be quickly disassembled and separated from the machine body to remove the residual glue.

HuiNuo JTM-300 Small continuous coaterSpecifications

| LIST | VALUE |

|---|---|

| Coating Method | continuous scratch coating |

| Effective application width | ≤ 300mm, adjustable through baffle |

| Drawdown blade adjustment | manual adjustment |

| Spreader roller diameter | Ф50mm |

| Spreader thickness range | 0.01mm~2mm |

| Minimum gluing thickness | 0.01Mm (depending on the slurry, refer to the material requirements) |

| Coating surface density | ≤ +/- 1.5% (including substrate, excluding edge anomalies) |

| Coating Speed | 2~ 4.5M/min forward and reverse stepless transmission |

| Film Accuracy | +/- 0.003mm (depending on slurry, reference material requirements) |

| Regulator resolution | 0.001mm |

| Indication Display mode | digital display |

| Heating device | Chute heating |

| Heating mode | Heating rod |

| Temperature range | RT+~200℃ |

| box Volume | About 0.5L |

| Width of guide roller | 300mm |

| substrate width | Max.300mm |

| Back roller diameter | Ф150mm |

| Reel diameter | 3 inches. |

| rewinding diameter | Max.Ф450mm |

| Applicable materials | hot-melt adhesive |

| Machine Power | 1050W |

| Host Power Supply | AC220V (single phase) 50Hz |

| Machine size | 1051*635*600mm |

| Machine Weight | About 120kg |

HuiNuo JTM-300 Small continuous coater Packing list

Equipment machine × 1, dial meter x2, power cord × 1, warranty card & manual x1, certificate of conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

JTM-300

JTM-300