JINGKELIAN JKCH dual-use Thickness Gauge, suitable for magnetic/nonmagnetic metal substrates, using magnetic and eddy current thickness measurement

Measurement range 0~1250um or 0~50mil, indication accuracy +/- [( 1%~ 3%) H + 1um], the minimum measurement curvature convex radius: 5mm, using a magnetic and eddy current thickness measurement method, nondestructive measurement magnetic metal substrate nonmagnetic thickness of the coating layer and the thickness of the nonconductive coating layer on the nonmagnetic metal substrate.

JingKeLian

JingKeLian-

AMITTARI AC-112BS split Coating Thickness Gauge with statistical function

$ 515.00 -

LANDTEK CM8829F magnetic Film Thickness Gauge, one-piece, thickness range 0~3mm

$ 451.00 -

TQC SP1114 Destructiveness Thickness Gauge Blade 4 Blade 2~ 200μm Range

$ 289.00 -

IWAVE WH91 split coating Film thickness meter Iron base

$ 182.00 -

LEEB N1 Probe for use with leeb221 and leeb222 Coating Thickness Gauges

Login

Overview of JKCH dual-purpose Thickness Gauge

JKCH magnetic and non-magnetic dual-purpose Thickness Gauge adopts magnetic and eddy current thickness measurement methods, which can non-destructively measure the thickness of non-magnetic coatings (such as aluminum, chromium, etc.) on magnetic metal substrates (such as steel, iron, alloys and hard magnetic steel, etc.) , copper, enamel, rubber, paint, etc.) and the thickness of the non-conductive covering layer on the non-magnetic metal substrate (such as copper, aluminum, zinc, tin, etc.) (such as enamel, rubber, paint, plastic, etc.)

Features and applications

The magnetic and non-magnetic dual-purpose Thickness Gauge has the characteristics of small measurement error, high reliability, good stability and easy operation. It is a testing instrument required to control and ensure product quality. It is widely used in manufacturing, metal processing industry, chemical industry and so on. Industrial, commodity inspection and other testing fields.

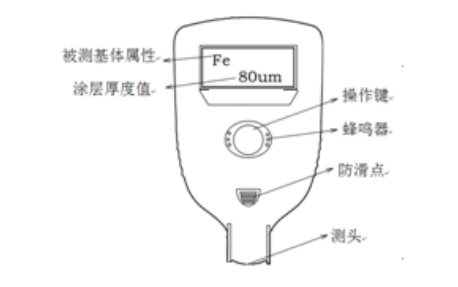

JKCH dual-purpose Thickness Gauge structure diagram

JingKeLian JKCH-1250 Dual-use Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Principle of thickness measurement | Magnetic Induction and eddy Current |

| Indication Accuracy | +/- [ (1%~ 3%) H + 1um] (Note: H is the thickness reading) |

| matrix thickness | Minimum thickness: 0.2mm; Minimum measurement surface: 15mm |

| Power Supply | 4 AAA batteries (if not used for a long time, please remove the battery) |

| Weight | 82G (without battery) |

| Dimensions | 112×69×28mm |

JingKeLian JKCH-1250 Dual-use Thickness Gauge Packing list

Dual-use thickness gauge x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveGB/T 44757-2024

- ActiveQJ 990.3A-2011

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveISO 2178-2016

- ActiveASTM D7091-2022

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishISO 2808-2007

- AbolishGB/T 1764-1979

- ActiveGB/T 13452.2-2008

- ActiveGB/T 11374-2012

- ActiveGB/T 4957-2003