US Phase II PTG-3700 Coating Thickness Gauge/spray paint Thickness Gauge, integrated probe

The US Phase II PTG-3700 Coating Thickness Gauge is a coating spray paint Thickness Gauge with a built-in probe. The thickness measurement range is 0~1250µm. The PTG-3700 Coating Thickness Gauge measurement surface is 5mm in diameter. Measuring temperature is up to 150 ℃.

PhaseII

PhaseII-

LINSHANG LS239 Paint film instrument, car paint Thickness detection instrument Iron and aluminum substrate identification Bluetooth report

$ 176.00 -

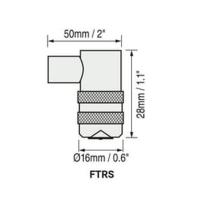

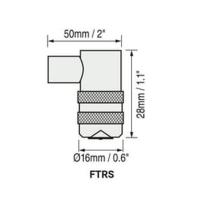

Defelsko FTRS Thickness Gauge Probe

$ 912.00 -

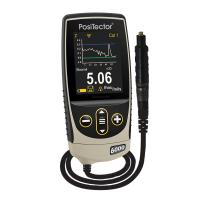

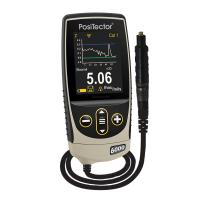

Defelsko PosiTector 6000 N0S3 imported platings Thickness Gauge

$ 1818.00 -

CHINA CTG-802-1500FV cylindrical coating Thickness Gauge, split iron-based large V type, suitable for surface measurement

$ 230.00 -

Germany EPK MikroTest NiFe50 McCourt Eletroplating Nickel Thickness Gauge, Thickness Measurement: 0~50μm

$ 2609.00

New! The Phase II PTG-3700 Coating Thickness Gauge/Paint Thickness Gauge is a professional Thickness Gauge that makes it easy to measure the thickness of non-magnetic coatings on magnetic substrates and the thickness of non-conductive layers on non-magnetic substrates. The PTG-3700 Coating Thickness Gauge uses an all-in-one auto-identified transducer, while the PTG-3750 uses an external probe.

This automatic identification probe makes use of the principle of eddy current and electromagnetic induction.

The PTG-3700 Series Coating Thickness Gauges feature the following features and functions: large screen, backlight, large measurement range, professional storage, browsing and data analysis capabilities, such as maximum and minimum average and counting functions

The PTG-3700 Coating Thickness Gauge is used in a wide range of applications including manufacturing, general engineering, commodity inspection and automotive.

Technical parameters

Measuring range: 0-1250 μ m

Resolution: 0.1 μm for measurements from 0-99 μm; When the measured value ≥ 100 μm is 1 μm

Indication accuracy: +/- 1-3%N or ±2μm after 1 point calibration

Minimum measuring area: 5mm x 5mm Minimum substrate thickness 0.5mm for ferrous substrates and 50mm for non-ferrous substrates

Minimum radius of curvature: 3 mm convex surface, 30 mm concave surface, maximum surface temperature: 150°C (maximum contact time is 2 seconds) Power supply: 2 AAA batteries

Dimensions and shapes 126 x 65 x 35mm .

The PTG-3700 uses an integrated probe to automatically detect both magnetic and non-magnetic substrates. Comes with 2 types of substrates (iron-based, aluminum-based), 4 calibration specimens, suitcase, battery, instruction manual

PhaseII PTG-3700 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0~1250µm |

| margin of error | ±3% |

| resolution | 0.1μm|1μm |

| Minimum measurement surface | Φ5mm |

| Minimum radius of curvature | Convex 3mm; Concave 30mm |

| thinnest substrate | 0.5mm(F);50mm(N) |

| probe | Integrated probe |

| Power Supply | 2 * AAA Battery |

| system language | Chinese |

| Display screen | LCD screen |

| Dimension | 126*65*35mm |

| Minimum measurement surface | 5*5mm |

| Probe contact temperature | 150 ℃ (contact time up to 2 seconds) |

PhaseII PTG-3700 Coating Thickness Gauge Packing list

Host X1, base X2, calibrated test piece X4, suitcase X1, battery X1, instruction manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

- How to use ultrasonic Thickness Gauge?

- Analysis of Thickness Measurement Method for Coating Thickness Measurement

- Which Coating Thickness Gauge is Right for You?

- Eletroplating coated Film thickness is insufficient or Film thickness is too large

- Three precautions for the use of paint film coating Thickness Gauges

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 5367.1-2018

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveISO 2178-2016

- ActiveASTM D7091-2022

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveHG/T 3885-2006

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- ActiveGB/T 5209-1985

- AbolishASTM G12-07-2013

- AbolishISO 2808-2007

PTG-3700

PTG-3700