TIME TT130 Ultrasonic Thickness Gauge Suitable for Metals, Plastics, Ceramics, Glass, Sheets, Parts, etc

TIME TT130 Ultrasonic Thickness Gauge measurement material thickness 0.75~ 300mm, is a split probe Thickness Gauge, TT130 Sensors contact temperature -10~60 ℃, can store 10 thickness measurement values, 5 Speed of sound values.

TIME

TIME-

QILI UT800 Ultrasonic Thickness Gauge metal plastic thickness measurement

$ 369.00 -

Ultrasonic wall Thickness Gauge DC-2030C Deguang electronic measurement of cast iron and other Film thickness

$ 943.00 -

LANDTEK TM8816 Ultrasonic Thickness Gauge Suitable for Petroleum, Shipbuilding, Machine Manufacturing and Pressure Vessel, Chemical Equipment Boiler, etc

$ 348.00 -

Ultrasonic steel plate Thickness Gauge DC-2010C Deguang electronic measurement of steel plate material itself Film thickness

$ 817.00 -

DUBAN DB22-TM240T3 Penetrating coating Ultrasonic Thickness Gauge

$ 433.00

Overview

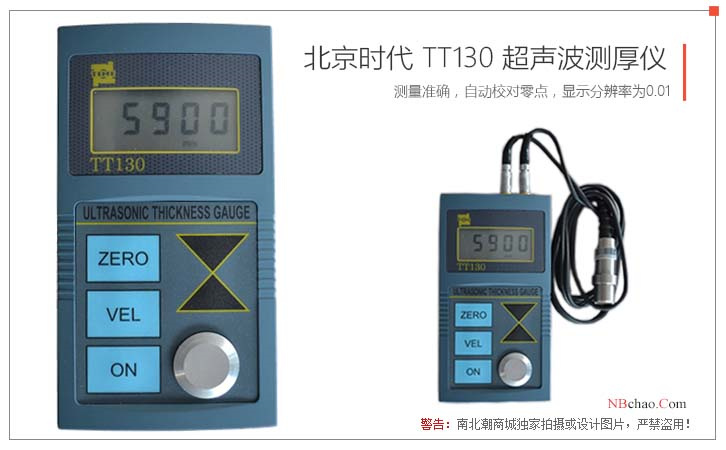

The TT130 ultrasonic Thickness Gauge has a display resolution of 0.01, which can measure more precise workpieces than the TT100 model, with accurate measurement and automatic zero point calibration. Beijing Times Ultrasonic Thickness Gauge Series is a collection of contemporary science and technology electronic technology and measurement technology in one, professional non-destructive testing instruments, the use of microcomputer analysis, processing, display, the use of highly optimized measurement circuit, with high measurement accuracy, wide range, easy operation, stable work and other specific. This principle can be used to measure all kinds of materials that can make ultrasonic waves propagate inside at a certain speed, such as metals, plastics, ceramics, glass, etc., and can accurately measure various plates and processed parts.

Live shot

Operating Principle

When the ultrasonic pulse emitted by the probe reaches the material interface through the measured object, the pulse is reflected back to the probe, and the thickness of the measured material is determined by accurately measuring the time of ultrasonic wave propagation in the material.

Parameters

| performance | TT130 |

| Measuring range | 0.75~300mm |

| Display resolution | 0.01mm |

| Sound velocity range | 1000~9999m/s |

| Workpiece surface temperature | -10~60 degrees |

| display | Four-digit LCD display |

| Indication error | +_(1%H+0.1mm), H is the actual thickness value |

| Lower Pipe Measurement Limit | ¢20mmx3.0mm (5P¢10 probe, steel) |

| Operating time | 250 hours of continuous operation (2 AA alkaline batteries, 1.5V/pcs) |

Features

1. High resolution: the display resolution is 0.01mm when measuring workpieces below 100mm;

2. Automatic calibration of zero point: the systematic error can be corrected;

3. Coupling prompt, low Voltage prompt;

4. Shutdown mode: It will automatically shut down after three minutes of no operation;

5. Sound velocity adjustment: the sound velocity can be measured by using a test block of known thickness;

6. Data storage: 10 thickness values and 5 sound velocity values can be stored;

Basic configuration

| valise | 1 pc |

| host | 1 unit |

| Console case | 1 set |

| probe | 1 5P¢10/90 probe |

| battery | 2 AA alkaline batteries |

| Couplant | 1 bottle |

| Random files | 1 set |

TIME TT130 Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 0.75~300mm |

| Probe Frequency | 5MHz |

| Probe style | Split probe (5P < 10 probe) |

| Probe diameter | Φ10mm |

| Probe contact temperature | -10~60℃ |

| Lower limit of pipe measurement | Φ20*3mm |

| Measurement error | ±(1%H+0.1)mm |

| Display resolution | 0.01mm |

| Storage Capacity | 10 Measured values, 5 Speed of sound values |

| Speed of sound | 1000~9999m/s |

| Display | Four-digit LCD display |

| Operating language | Chinese |

| Application Software | without |

| Power Supply | 2 * 1.5V AA alkaline battery |

| Operating Time | 250h |

| Application | Metals, Plastics, Ceramics, Glass, etc. can make accurate measurement of various plates and processed parts |

TIME TT130 Ultrasonic Thickness Gauge Packing list

host x1, suitcase x1, host protective cover x1, 5P < unk > 10/90 probe x1, AA type alkaline battery x2, coupling agent x1, random file x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Ultrasonic Thickness Gauge in Oil Drilling Tools Production

- Application of Ultrasonic Thickness Gauge in Spinning Tube Abrasion Monitoring

- Influencing factors of ultrasonic thickness indication distortion

- Application of Ultrasonic Thickness Measurement Technology- "Selection of Thickness Gauges"

- How to measure the thickness of galvanized layer _ galvanized layer thickness inspection method

- GB/T13452.2-2008 Determination of film thickness of Paints and varnishes [text version]

- Ultrasonic Instrument FAQ

- How to choose a Thickness Gauge?

- Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- Discussion on Thickness Measurement of Industrial Pipeline