ANGNI AE300L-P Mulser Rotation speed 0~11000rpm

High performance motor, strong torque, stable operation, high kinetic energy, Speed range: 200-11000rpm (70G)

AN

AN-

Huxi HR-90Z Pilot High-Shear Dispersing Emulsifier electric lift/220V

$ 4792.00 -

MUXUAN MXR-15-3 Three-stage emulsification pump line type high shear homogeneous Mulser 15kw

$ 3933.00 -

QIWEI JRH-1000S Laboratory Mulser Power 1100W/8000rpm

$ 768.00 -

ANGNI AD500S-H (12G) High Speed Dispersion Mulser Suitable for viscosity 5000mPa·s

$ 932.00 -

MUXUAN MS-D25 Laboratory Online High Shear Dispersion Mulser SUS316L Material 500W

$ 2045.00

Introduction

AE300L-P high-speed shearing dispersing and emulsifying machine is driven by a compact series-excited micro-high-speed motor, which is suitable for stirring and mixing low to medium and high viscosity liquids in laboratories or pilot plants, and shearing of crushed granular materials in liquid media emulsification. The machine is composed of high-density die-casting aluminum alloy as the body of the drive motor, high-quality stainless steel refined shear emulsification working head and speed controller.

Principle

The high-speed shearing dispersing emulsifying machine is driven by a high-speed motor to shear and emulsify the working head. The precisely matched working head rotates the stator, and under the high-speed rotation of the rotor , comprehensive kinetic energy such as high-frequency, strong circumferential tangential velocity, and angular velocity is formed, so that the experimental materials are sucked into the rotor area from the bottom of the experimental container, and under the action of huge centrifugal force Throw it out of the stator hole. The stator and rotor form strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects in a reasonably narrow gap. The experimental materials cycle through the above working process in the container, and withstand tens of thousands of times of shearing, tearing, impacting and mixing per minute, so as to achieve the effect of shear emulsification, and its efficiency is about a thousand times higher than that of ordinary stirring.

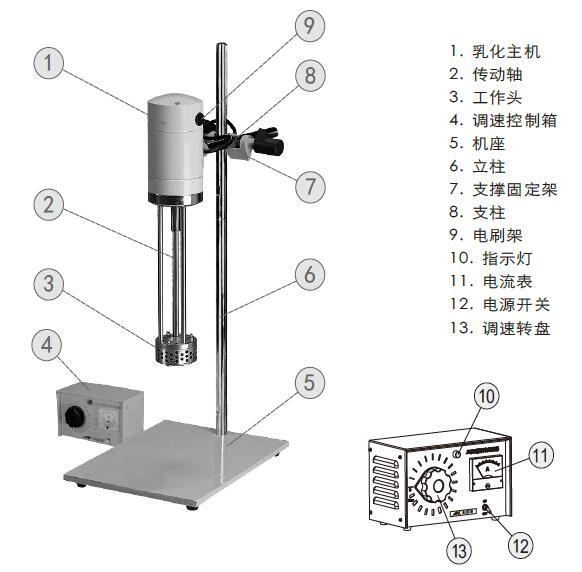

Functional Structure Diagram

Application

The AE300L-P laboratory shear emulsifier is suitable for tissue dispersion in the field of biotechnology, sample preparation in the field of medicine, enzyme treatment in the food industry, and liquid-to-liquid, liquid-to-liquid phases in the pharmaceutical industry, cosmetics industry, paint industry, and petrochemical industry. Experimental aspects of the solid phase. Under the triple action of extrusion in the feed liquid, strong impact and pressure loss expansion, the experimental medium can be refined and mixed more evenly to prevent or reduce delamination with the feed liquid. Such as: homogenization and emulsification process in the production process of dairy products, beverages, cosmetics, pharmaceuticals and other products.

AN AE300L-P High Speed Shear Dispersion MulserSpecifications

| LIST | VALUE |

|---|---|

| Processing Capacity | 500~40000mL |

| Operating Mode | S1 (continuous) |

| Speed regulation mode | stepless speed regulation |

| Speed range | 200~12000rpm |

| Rotor maximum linear velocity | 19m/s |

| Rated torque | 0.96 N.m |

| Input Power | 510W |

| output power | 300W |

| Power | AC 220V 50/60Hz |

| Work head specification | Φ70mm |

| Work head material | SS304 |

| Rated torque | 22.0 N.cm |

| Max. Processing Viscosity | 8000cp |

| Maximum feed particle size | 18 m/s |

| Ambient Temperature | ≤40℃ |

| Allowable Relative Humidity | ≤80% |

| Dimensions | 215*310*720mm |

| Machine Weight | 13.8kg |

| Minimum immersion liquid height | 50mm |

| Maximum immersion liquid height | 236mm |

| Stator standard configuration | 5mm² 20mm² 50mm² |

AN AE300L-P High Speed Shear Dispersion Mulser Packing list

Mulser x1, manual x1, warranty card x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- HANNA HI96821 Digital refractometer operation guide

- Classification and Application of Formula Guide

- Lab Film Applicators for prepative polypropylene (PP) nitrile films

- Selection guide for Surface Tensiometers

- Critical surface tension and its role in pigment wettability

- Demonstration of RCA wear-resistant tape machine

- Difference Between Halogen Moisture Analyzer and Thermogravimeter

- Calibration Terms - Coating Thickness Gages

- Application and test method of UV accelerated weathering Test Chamber in automotive Glass film

- The performance of lithium button batteries needs to be tested

AE300L-P

AE300L-P