MODERNER FZ-II film adhesion Tester, an instrument for determining the adhesion ability of various films to the surface of the coating

Used to determine the adhesion ability of various films to the surface of the coating. Tracing diameter 0~10.5mm, working stroke ≥ 80mm

Moderner

Moderner-

JFL QFZ film adhesion Tester

$ 395.00 -

PUSHEN QFZ-II Circle-drawing method paint film adhesion Tester

$ 403.00 -

TRUIT TR 3599/2 Automatic Circular Adhesion Tester

$ 1366.00 -

JINGKELIAN QFZ Adhesion Tester Drawing Diameter 0~10.5mm

$ 318.00 -

MODERNER FZ-II film adhesion Tester, an instrument for determining the adhesion ability of various films to the surface of the coating

Login

The main technical parameters of the paint film adhesion Tester

The diameter of the depicted figure: 0~10.5mm

Effective area of worktable: 50mmx100mm

Weight: 500gx1 200gx2 100gx1

Needle: 808 grade stylus (use less than 5 times)

Effective stroke of the table: not less than 80mm

Paint film adhesion Tester use

FZ-II Paint Film Adhesion Tester (also known as Paint Film Adhesion Tester) is used to determine the adhesion ability of various coating films to the surface of the coated object.

Paint film adhesion Tester product diagram

The structural principle of the paint film adhesion Tester

This FZ-II paint film adhesion Tester is a desktop manual and is divided into four parts.

1. The main transmission part is composed of a handwheel, a sprocket, and a helical helical gear, and the workbench moves left and right when the handwheel is turned, and the needle is drawing a circle at the same time.

2. The depiction head is composed of the following two components.

a) Double-ended screws are used to adjust the upper and lower parts of the machine head.

b) A lower dovetail plate that is connected by a sliding dovetail and a screw to drive the hand drawing needle to adjust the diameter of the depiction.

3. The workbench part is equipped with a liftable half nut at one end and connects with the lead screw to drive the workbench to move back and forth, and there are four nuts and two pressing plates on the workbench to press and release the test piece.

4. The base part is used to support the workbench and the stroke.

How to use the paint film adhesion Tester

1) Prepare the sample according to the specified requirements.

2) Check the steel needle, it is better to replace it with a new steel needle at the beginning of use, and the needle tip is about 3mm away from the work surface.

3) Adjust the eccentric position of the needle tip according to the required depicted diameter, and then tighten it with screws.

4) Press the prepared sample with the coating side up on the workbench and press it with a pressing plate.

5) Add weights to the plate on the weight plate according to the requirements of the regulations.

6) Lift the movable half nut to move the table to the outer end, and then put down the movable half nut.

7) Toggle the pressure rod so that the needle tip is in contact with the membrane surface.

8) Shake the handwheel, then the steel needle depicts a spiral pattern on the model, and the adhesion of the coating film can be judged to be excellent, good, medium, poor and inferior according to the pattern.

9) Take out the sample, remove the paint chips from the scratches with a paint brush, check the scratches with a quadruple magnifying glass and grade them.

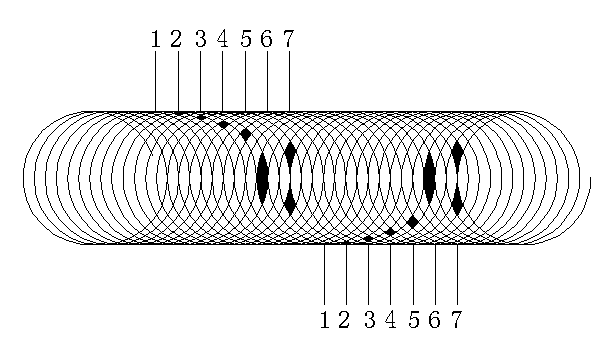

Taking the upper side of the scratch on the model as the target of inspection, seven parts are marked in turn, including 1, 2, 3, 4, 5, 6, and 7. Correspondingly, there are seven levels. Check the integrity of the paint film of each part in order, if more than 70% of the lattice of a certain part is intact, it is determined that the part is intact, otherwise it should be considered damaged. For example, if the paint film of part 1 is intact and the adhesion is good, it is classified as grade 1, and if the paint film of part 1 is damaged and part 2 is intact, the adhesion is second, and it is rated as grade 2. By analogy, grade 7 is the worst adhesion.

The standard scratch round roller line is shown in the figure:

Results are based on the same level of at least two templates.

Maintenance, storage and transportation

1. The sliding part should be oiled frequently (No. 20 engine oil and petroleum jelly) to prevent rust.

2. Before the measurement work, the oil hole and guide rail of the instrument should be lubricated and used horizontally.

3. Beware of colliding with steel needles when moving the workbench.

4. A steel needle is generally used 5 times before it has to be replaced.

5. During the test, the needle needs to be pierced to the bottom of the paint film, and the drawn figure shall prevail.

6. This FZ-II paint film adhesion Tester is not suitable for wood or plastic samples.

7. The FZ-II paint film adhesion Tester should be cleaned up after use, and properly covered to prevent dust and moisture.

8. When not used for a long time and transported, it should be wrapped in a plastic bag, with a built-in desiccant, a protective wooden box on the outside, and a soft material on the inside, so as to avoid vibration and affect the use of the instrument.

9. The FZ-II paint film adhesion Tester is calculated from the time the manufacturer sends it to the user, and within one year under the conditions of use, maintenance, storage and transportation in accordance with this description, when the use is affected by the adverse manufacturing quality, our factory will repair it free of charge, except for the steel needle as a consumable.

Packing list

A) 1 main unit

B) Accessories: 1. 4 weights, 2. 1 box of steel needles, 3. 1 manual

Moderner FZ-II Film adhesion TesterSpecifications

| LIST | VALUE |

|---|---|

| type | manual |

| trace diameter | 0~10.5mm |

| needle | 808 grade stylus (used less than 5 times) |

| Working Travel | ≥80mm |

| Nominal Mass | 100g、500g、200g、200g |

| Effective area of workbench | 100*50mm |

Moderner FZ-II Film adhesion Tester Packing list

Host x1, weight x4, steel needle x1, manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveSJ 20910A-2018

- ActiveWJ 2669-2005

- ActiveJG/T 572-2019

- Active 036-2020

- ActiveGB/T 13217.7-2023

- ActiveGB/T 41899-2022

- ActiveHG/T 3369-2003

- ActiveHG/T 3355-2003

- ActiveHG/T 3349-2003

- ActiveGB/T 1720-2020

- ActiveQB/T 2025-2013

- ActiveHG/T 2661-1995

- ActiveJB/T 6504-1992

- AbolishGB/T 1720-1979

FZ-II

FZ-II