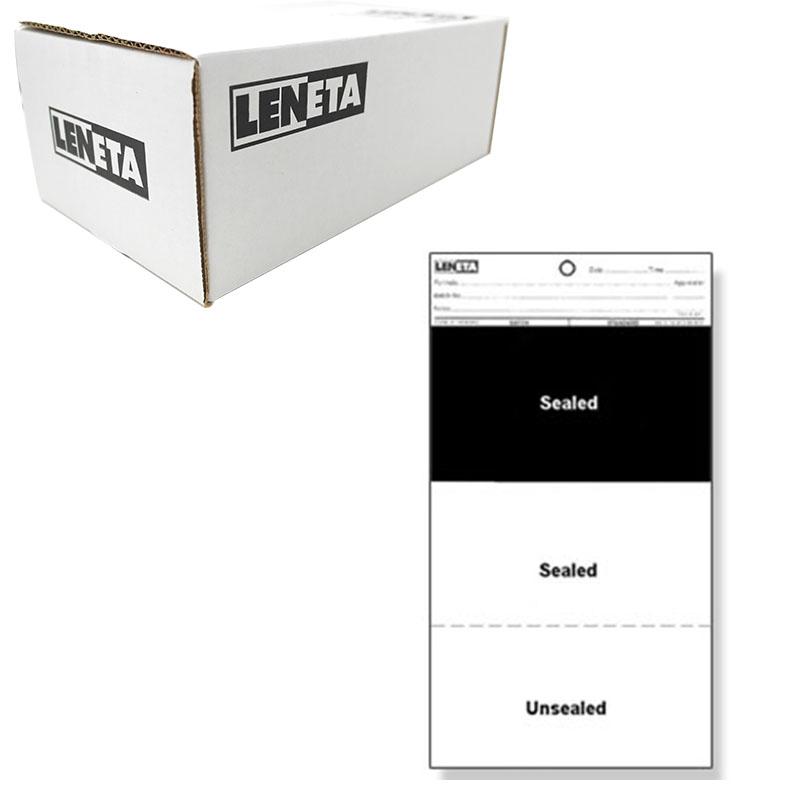

Leneta 1A Opacity Chart Black sealed in white sealed in white unsealed

The Leneta From 1A Opacity Chart measures 140 x 254 in a box of 250 sheets, meeting ASTM international standards.

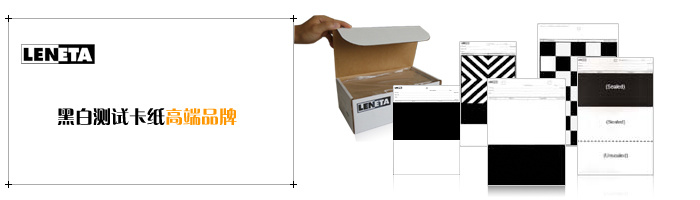

LENETA

LENETA-

RDS 38 #1/4 "wire-wound Applicator rod film thickness 86.9μm Wire diameter 0.97mm

$ 157.00 -

JINGKELIAN QAG Paints sagging Tester for relative sagging tests

$ 402.00 -

Japan OSP-12/250 paint scraper stick WFT 12μm length 250mm

$ 154.00 -

MODERNER SZQ-500 (GB Bird-type) Wet Film Applicator film width 78mm

Login -

UK RK KHC.20 Small Drawdown Plate prepative Common Spreader Platform

$ 174.00

Leneta From 1A is a kind of black and white overlay varnish cardboard, the top part of the cardboard is black overlay varnish, the middle part is white overlay varnish, and the lower part is white uncovered varnish, which is a special product for measuring the hiding force.The specifications and sizes of Leneta From 1A concealment paper are as follows:140 x 254, each box is 250 sheets, in accordance with ASTM international standards.

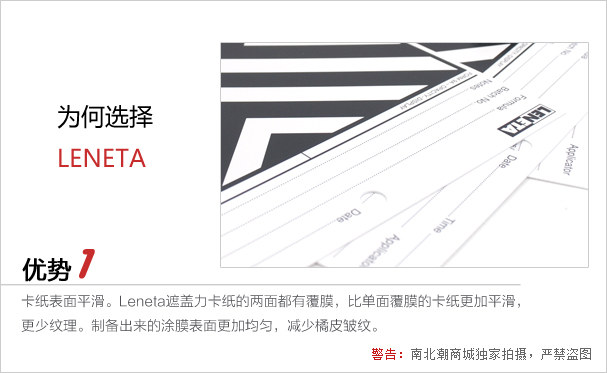

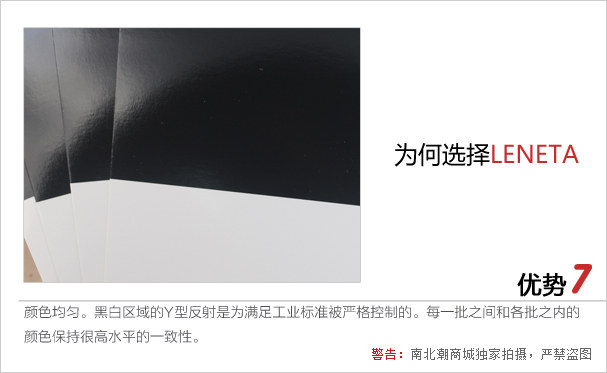

Leneta's Seven Advantages of Concealing Power Paper

Parameters

| Model | Size(mm) | color | Quantity per box (sheets) | standard | Material | apply |

| Form 1A | 140 x 254 | The upper black cover varnish, the medium white cover varnish, and the lower white uncovered varnish | 250 | ASTM | Overcoat varnish and unvarnish varnish | Coatings and inks |

| Form 1B | 194 x 289 | The upper black cover varnish, the medium white cover varnish, and the lower white uncovered varnish | 250 | ASTM |

The choice of covering power cardboard is related to the coating process

Different paint formulations require test cardboard to have different dissolution resistancesexual, stronger or weaker. Different types of resins should be used with inadequate solvents. The polarity of a solvent dictates that its organic components can be activated more and less. In response to this problem, two types of test jams are available.

Solve the problem of poor paint coverage

The color of the underlying surface can be seen through the paint film, which often occurs in hard-to-paint areas, such as underbody skidders or sharp corners.

1. Reasons for poor paint covering power

The thickness of the paint layer is not enough, and the paint has poor hiding power. The reasons for this are:

a) Improper spraying method.

b) Poor lighting conditions, narrow working space, difficult access to the spraying surface.

c) The paint is mixed unevenly.

d) The thickness of the paint layer is reduced due to excessive grinding and polishing.

2. How to prevent poor hiding power of paints and other coatings

a) Use the correct spraying method to ensure that the thickness of the paint film is appropriate, smooth and uniform.

b) The space of the spray booth should be suitable, the lighting conditions should be good, and special attention should be paid to the spraying quality of the inaccessible area when spraying.

c) The paint should be effectively mixed evenly.

d) It is forbidden to over-polish the paint film. Pay special attention to the corner areas.

3. Paint covering repair method

Smooth out the defective area and repaint.

Measurement of hiding power

The basic consideration for the sale of architectural coatings is the hiding power and yield, which is the determination of the hiding power of the paint, that is, how many coatings need to be applied to a complete coating film, and how many barrels of paint are needed

Hiding power is a measure of the ability to cover.

Hiding power, also known as hiding rate (%) = Y black/Y white * 100 (%)

A 100% coverage rate is complete coverage, i.e. there is no difference between the black and white areas after application.

Directions:

1. Evenly coat paint and other coatings on the paint hiding power test paper according to the coating steps.

2. After the coating film is fully dried by air, the instrument is used for objective evaluation.

3. The value of the hiding force can be measured within 1 second and displayed automatically.

Paint hiding power test paper is not only limited to the measurement of the hiding power of paints and other coatings, but also the corresponding hiding power test method can also be applied to the detection of the hiding rate of transparent films and plastic products.

LENETA cardboard main types

Opacity test strips: Large patches of black and large patches of white are used to test the hiding power of the coating

Penopac Strips: Permeability and hiding tests are performed simultaneously in one table

Display: Uses a twill pattern to help show the hiding power of the coating

Opacity display: A combination of large black, large white, and twill patterns

Coating rate test strip: larger than other cards, used to measure the coating rate of coatings

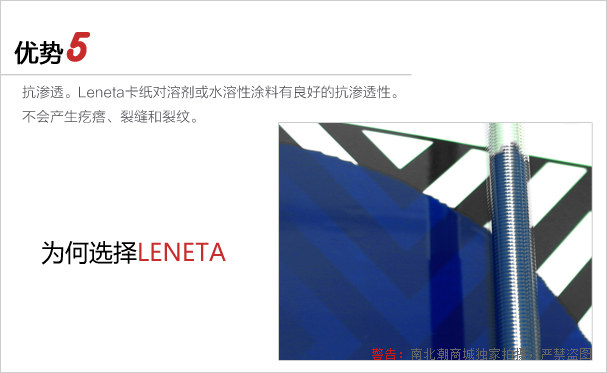

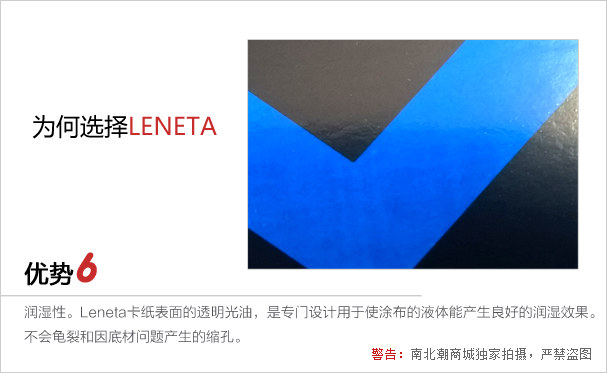

Actual picture of the product

Covering power paper related configurations [sold separately]

Coating rods

Coating rods provide an economical and convenient way to prepare coatings with uniform filmness

Simple to use and easy to clean

Firmly hold the jammed paper in place when coating

Helps to achieve even results

Leveling and sagging test

Leneta Leveling Test (see ASTM D 4062)

A. Equipment

1.Leneta leveler, product number LTB-2;

2. Coating leveling standard, product number LS-2;

3. Leveling test coating plate, product number DP-2;

4. Scraping paper Form WB for light paint, Form 7B scraping paper for dark paint;

5. Padding, Form CP-2

6. Pre-cutting equipment, see page 36 of the catalog;

B. Preparation of paints

1. Stir completely and adjust the temperature to 23°C (73°F);

2. Filter and adjust viscosity if necessary;

3. Use one of the attached Pre-Shear Method descriptions to perform pre-cutting, and then test immediately.

C. Painting

1. Place the pad paper on the coating board.

2. Place the squeegee paper next to the left guide edge of the coating plate.

3. The leveler is placed at the top of the cardboard, and its long arm is next to the left guide side and towards the operator.

4. Place 8-10 ml of pre-cut paint on the tip of the leveler and apply quickly and evenly at a rate of approximately 60 cm/s (2 ft/s).

5. At 23°C (73°F), keep horizontal to dry.

D. Ratings

1. After drying, cut out a 3 x 5 inch (75 x 125 mm) piece of cardboard with stripes parallel to the long side.

2. Compare it with a Leneta coated leveling standard under suitable oblique light.

3. The matching standard number is the coating leveling value of Leneta. The high level of the rating is 10 and the lowest level is 0.

E. Practical Significance of Rating Values

This is based on subjective judgment. The following table is based on the consensus of an experienced laboratory collective:

Leneta Leveling Test (see ASTM D 4062)

Leneta Anti-Sagging Device Test Method (see ASTM D4400)

A. Instruments

1. Anti-sagging device 2. Adjustable straight edge, product number SE-1 3. Standard board for coating, product number DP-1 4. Scraping paper Form 7B for coating, used for light-colored paint. The white scratch paper Form WB is used for dark coatings. 5. Pad, Product No. CP-1 6. Pre-cut the equipment with a bottom-range anti-sagging, and the surface of the flat glass is better.

B. Preparation of paints

1. Stir evenly and adjust the temperature to 23°C (73.5°F) 2. Use one of the attached Pre-Shear Method descriptions to perform pre-shear, and then test immediately.

C. Painting

1. Place the straightener in the appropriate position of the standard plate for coating. 2. Place the test squeegee paper on the coating plate and clamp it. 3. Place the drogger on the scraper near the clamp, with the open-facing side of the sager facing the operator and its shoulders close to the straight-edged device. Place the pad paper. 4. Place an appropriate amount (8-10 ml) of pre-cut paint in front of the blade and apply at a constant speed of approximately 6 inches/second (150 mm/s). 5. Quickly and steadily place it vertically, so that the stripe is horizontal like a ladder erected, with the left (thinnest stripe) on it, and let it dry in this state.

D. Coating Grade

1. Match the coated stripes with the grooves on the anti-sagging. 2. Ignore the edges of the front and trail and look 150 mm (5-1/2 inches) in the center of the stripe, which is equivalent to the black area of the Form 7B. 3. The lowest (thickest) stripe that does not touch the stripe below is the logo stripe, and the corresponding number of grooves is the anti-sag index of the paint. 4. To get a more accurate anti-sag index, you need to add the number of grooves to the value of the increment and non-integration coefficient between the gaps (the coefficient that blends into the stripes below).

The non-integration coefficient can be estimated from the table below:

| Degree of integration | Non-integration coefficient |

| completely | 0 |

| Close to average | 0.25 |

| Less than average | 0.50 |

| More than average | 0.75 |

E. Rating Description

This is empirical or experimental, and highly subjective. It is important to emphasize that the sag resistance index is not a wet film thickness value. It is the gap of the indicated groove in mils, and as a result, the indicator fringe is about twice the thickness of the wet film. Neither the sag resistance index nor its corresponding approximate wet film thickness should be construed as a specific thickness in practice. It is a comparative tool, and it can only be achieved based on practical experience. Once the coating has shown good sag resistance in practice, the sag index can be measured and the sagging value of the specific formulation can therefore be controlled.

The anti-sag index may vary between different products. For example, latex paints generally have higher index values than solvent-based paints. The following judgment on sagging performance is based on observations of a range of general purpose high-gloss alkyd base coats and is for reference only. Do not take this as final.

Anti-sag index | Resistance to sagging |

3 | Very Poor |

The above indices cover the range of standard anti-sagging, but many coatings need to be tested for lower or higher index values. This gives rise to three other anti-sagging devices in the low, medium, and high index ranges. In this way, the measured value of the anti-sag index is extended to 1~60.

LENETA Form 1A Opacity ChartSpecifications

| LIST | VALUE |

|---|---|

| Specifications and Dimensions | 140*254mm |

| Color Style | Upper black sealed, medium white sealed, lower white unsealed |

| type | Sealed and unsealed |

| Encasement Specifications | 250 sheets |

| Application standard | ASTM |

| Application | Coating inks |

| Weight | 2.72kg |

LENETA Form 1A Opacity Chart Packing list

Encasement x1, Opacity Chart x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 3834-2006

- ActiveYS/T 680-2016

- ActiveGB/T 13217.5-2023

- ActiveGB/T 1727-2021

- ActiveGB/T 17001.6-2022

- ActiveGB/T 23997-2009

- ActiveHG/T 5776-2020

- ActiveGB/T 13217.1-2020

- ActiveGB/T 9756-2018

- ActiveASTM D5150-2017

- ActiveASTM D6441-05-2024

- AbolishGB/T 13217.1-2009

- AbolishGB/T 13217.5-2008

- AbolishGB/T 13217.6-2008

- AbolishGB/T 13217.5-2008

- ActiveASTM D5150-92-2017

- ActiveASTM D6762-2018

- ActiveHG/T 2244-1991

- ActiveHG/T 3851-2006

Form 1A

Form 1A