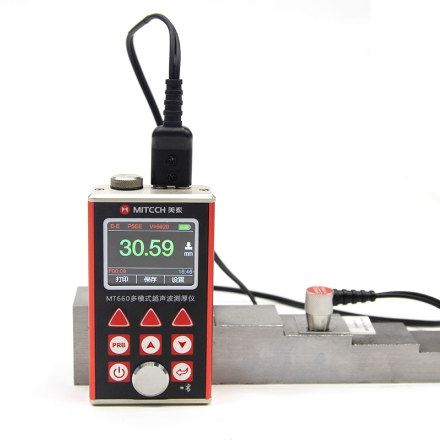

Mattel MT660 High Precision Ultrasonic Thickness Gauge coating Thickness range 3~ 100mm

Mattel MT660 High Precision Ultrasonic Thickness Gauge has two Measurement modes, can store and manage 100 sets of thickness data, MT660 High Precision Ultrasonic Thickness Gauge has the function of penetrating coating.

mitech

mitech-

Leeb322 Ultrasonic Thickness Gauge with a display resolution of 0.01mm

Login -

DONGRU DR89S Single Crystal Ultrasonic Thickness Gauge Standard 15P6 Probe

$ 1461.00 -

Deguang Electronics D7004 Ultrasonic Thickness Gauge Probe, mainly used for measurement of thin walls and small arcs

$ 324.00 -

LANDTEK TM8816 Ultrasonic Thickness Gauge Suitable for Petroleum, Shipbuilding, Machine Manufacturing and Pressure Vessel, Chemical Equipment Boiler, etc

$ 348.00 -

German EPK MiniTest 440 Ultrasonic Thickness Gauge Penetration coating thickness measurement

$ 2178.00

Overview

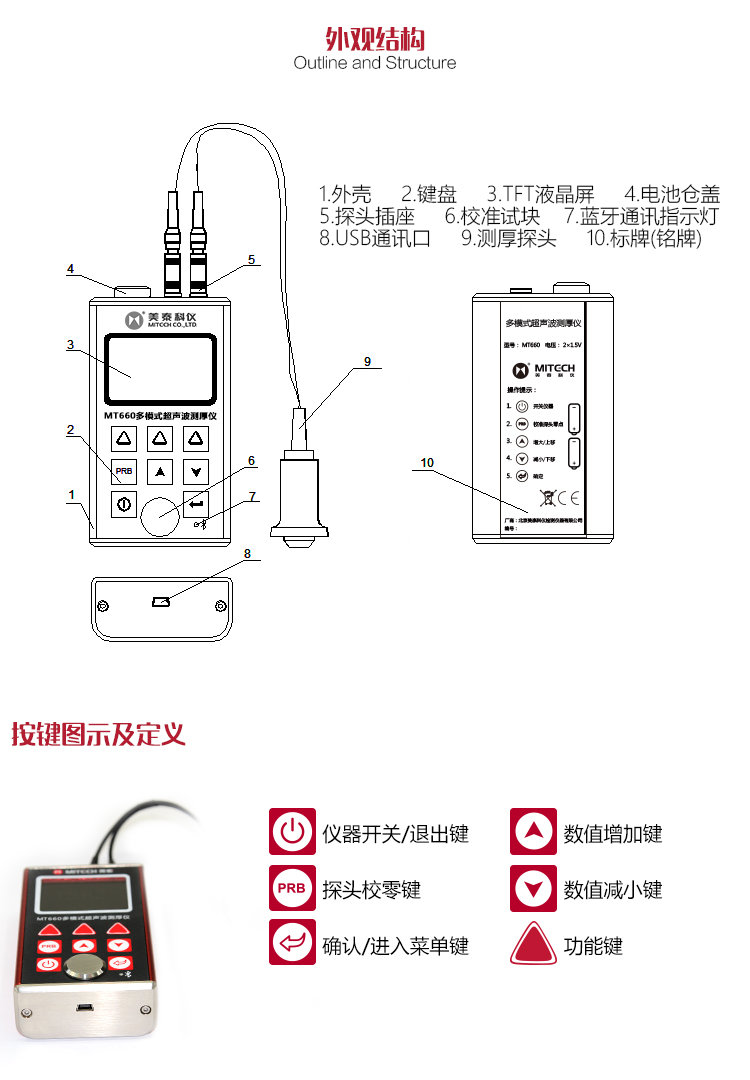

MT660 ultrasonic Thickness Gauge is a new upgraded product launched by Mattel, it pays more attention to user experience and functional innovation, using 320×240 color LCD screen, which can also present you with clear measurement results in dim light and strong sunlight environment, which greatly improves the visual experience, and the sealed aluminum alloy shell is exquisitely designed, smaller in size and better in quality, and is designed to defend against oil and dust in harsh on-site environments; Intelligent warning function, beyond the set range can be automatically prompted, can be convenient reading, to meet the effective collection of material multi-point thickness of accurate detection needs, support 0.001 high-precision display, Bluetooth communication, both through the coating mode and ordinary mode double effect function, its unique through the coating thickness measurement performance for the surface coated with paint or anti-corrosion materials of the workpiece thickness detection provides a more effective solution, no need to dispose of the surface coating before measurement, can be measured directly. It is widely used in the monitoring of the corrosion thinning degree of various pipelines and pressure vessels in production equipment in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields, and can also be used to accurately measure various plates and various processed parts. It is a professional precision instrument required to improve production efficiency and pass rate and save costs.

Features

It is suitable for measuring the thickness of metals (such as steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass, and any other ultrasonic conductor

The hermetically sealed metal enclosure is designed to protect against harsh field environments and is resistant to vibration, shock, and electromagnetic interference

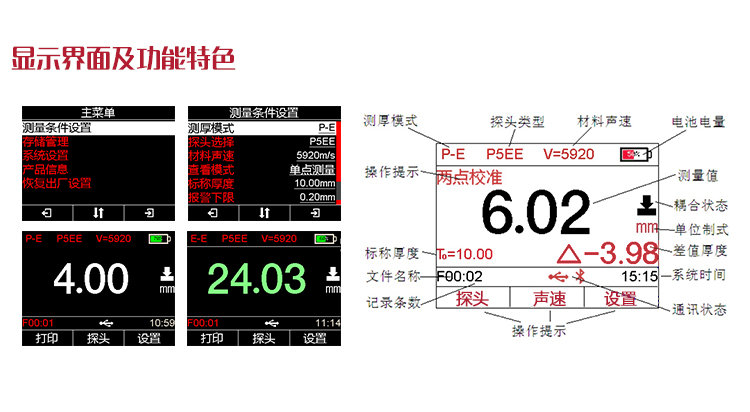

High-definition color LCD display, intelligent operation interface, intuitive display of measurement results, providing a good display experience

Two gauge modes: emission-echo mode and echo-echo mode, allow thickness measurements to be made through the coating without taking into account the coating thickness

Large-capacity storage, low-power design, can be used for more than several months

The known thickness can be used to measure the speed of sound back, which can meet the thickness detection needs of a variety of materials

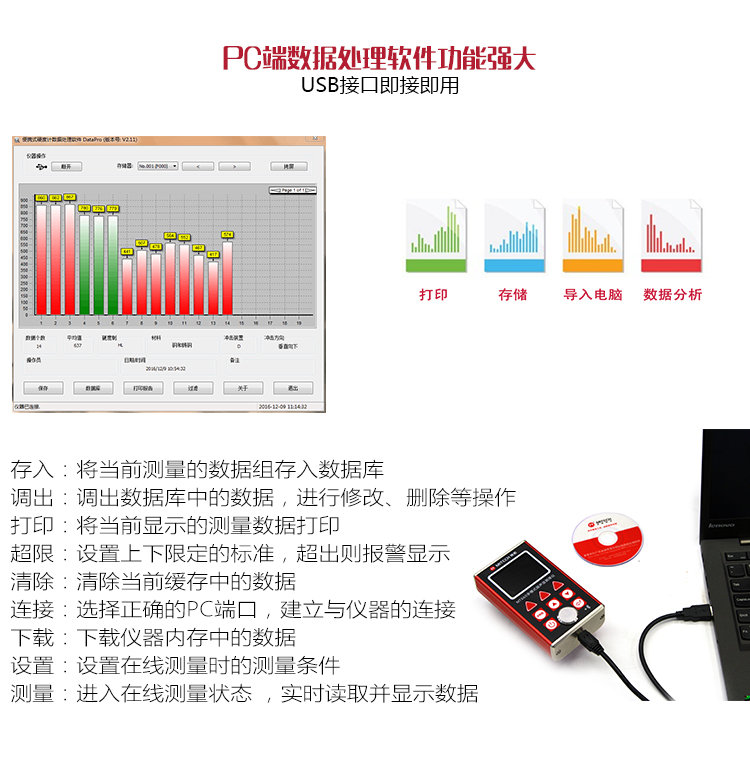

Equipped with USB data processing software, it can be connected to a computer for data analysis, storage, printing, etc

It can be compatible with a variety of probes with different frequencies and different element sizes

High-precision, high-resolution display, support 0.001 display resolution

It has the function of zero point calibration and two-point calibration of the probe, which can automatically correct the system error, and the high-precision probe equipped with narrow pulse composite wafer has a small blind spot and accurate measurement

The high-brightness EL backlit display is convenient for use in low-light environments

It supports on-site communication with Bluetooth printers, making it more convenient to use

The measurement results can be broadcast by voice, and the automatic alarm will be given when the measurement range is exceeded

It is equipped with power-saving functions such as automatic sleep and automatic shutdown, and the remaining power indication function

Functional use

It is suitable for measuring the thickness of metals (e.g. steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass, and any other good conductor of ultrasound

There are two thickness measurement modes: emission-echo mode and echo-echo mode, which allows thickness measurements to be made through the coating without taking the coating thickness into account

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

Known thicknesses can be used to backmeasure the speed of sound to improve measurement accuracy

The upper and lower limits of the thickness value can be set in advance, and the automatic alarm will be given when the range is exceeded

There are three viewing modes: single point measurement, maximum value measurement and difference measurement

It has the function of coupling status prompt to intuitively grasp the measurement status

The measurement results can be saved, with Bluetooth printing function, and can be connected to a Bluetooth printer to print the measurement results wirelessly

The LCD backlight has adjustable brightness, which is convenient for use in low-light environments

There is a residual battery indication function, which can display the remaining battery power in real time

It has power-saving functions such as automatic sleep and automatic shutdown

It can communicate with PC or smart terminal through Bluetooth and USB interfaces

It can be equipped with a variety of dual element transducers with different frequencies and different element sizes

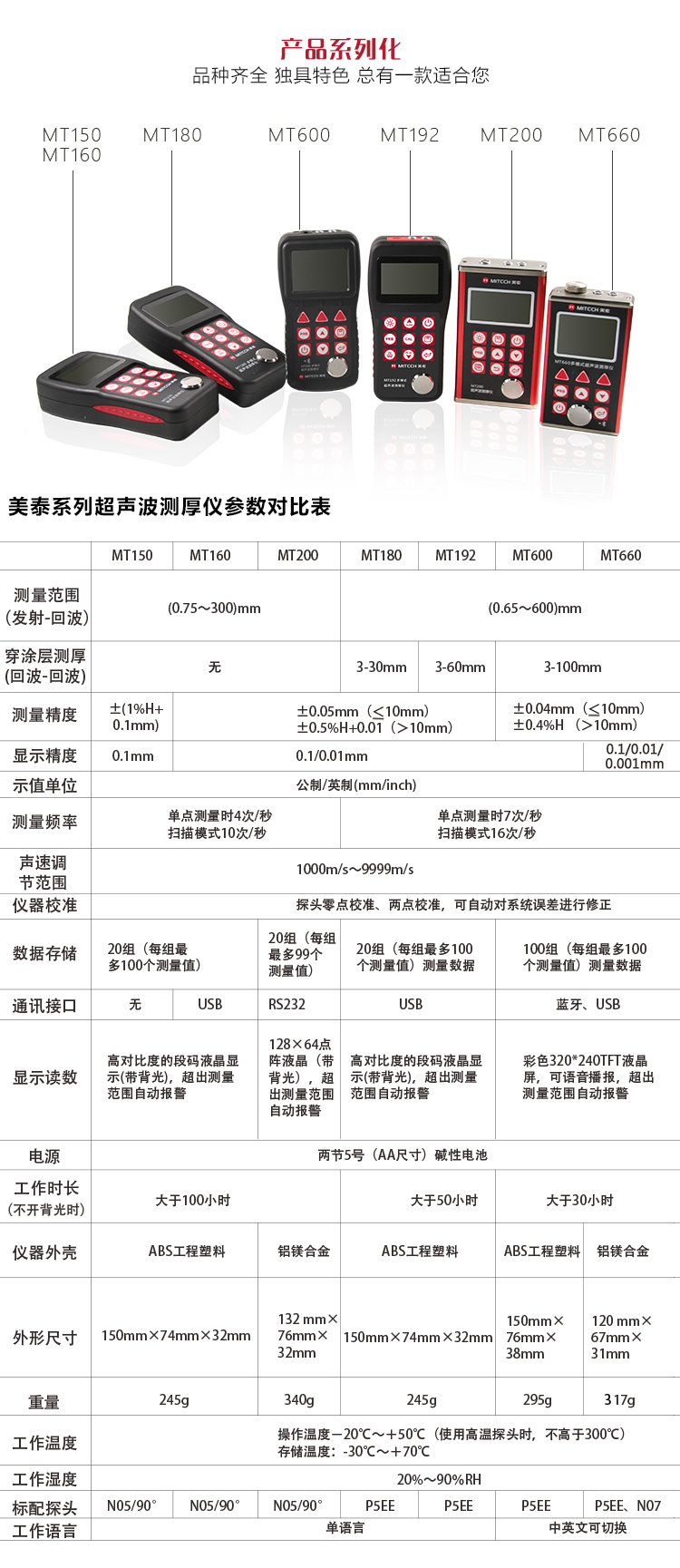

mitech MT660 Multimode Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | Emission-echo mode, (0.65~ 600) mm, echo-echo mode, (3~ 100) mm (45 #steel, P5EE) |

| Probe Frequency | (2.5-7)MHZ |

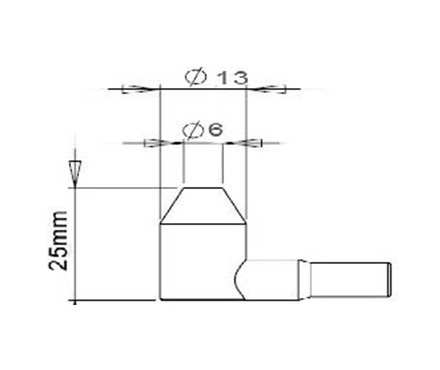

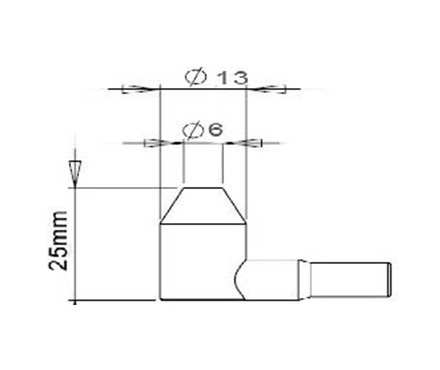

| Probe diameter | Thickness probe NO5 diameter 10MM, microcrystalline probe N07 diameter 6MM, high temperature probe HT5 diameter 12MM, narrow pulse thickness probe P5EE diameter 10MM, coarse crystal Probe diameter 12MM |

| minimum pipe diameter | Φ15mm×2.0mm |

| Display resolution | 0.1/0.01/0.001mm |

| error of indication | +/- 0.04mm (< 10mm ); +/- 0.4% Hmm (> 10mm), H is the thickness of the measured object |

| Measurement speed | Single point measurement 7 times per second, scanning mode 16 times per second |

| Display | Color 320 × 240 TFT LCD screen, adjustable backlight luminance |

| Speed of sound | 1000~9999m/s |

| Thickness measurement mode | Emission-Echo Mode (P-E) and Echo-Echo Mode (E-E) |

| Probe calibrated | Zero point calibrated, two point calibrated |

| Speed of sound | support |

| display mode | Single point measurement, maximum measurement and difference measurement |

| unit system | Metric or imperial (optional) |

| Operating language | Chinese and English can be switched. |

| Storage Capacity | Can store and manage 100 groups (up to 100 per group) of thickness data |

| Communication interface | Support Bluetooth and USB2.0 communication, and the host program can be upgraded online |

| data printing | Portable Bluetooth thermal printer to print measurement reports |

| Power Supply | Two AA size alkaline batteries, can work continuously for more than 30 hours (at default luminance) |

| Power saving method | With automatic screen standby, automatic sleep, automatic shutdown and other power-saving functions |

| Working time | More than 30 hours |

| Environmental requirements | Operating temperature 0 ℃~ + 50 ℃; Storage temperature: -20 ℃~ + 70 ℃ |

| Working Relative Humidity | ≤80% |

| Shell material | Aluminum magnesium alloy |

| Host size | 120*67*31mm |

| Machine Weight | 1.45KG |

| PC software | Yes. |

| voice broadcast data | Voice broadcast measurement results, automatic alarm beyond Measurement range |

mitech MT660 Multimode Ultrasonic Thickness Gauge Packing list

Instrument host x1, probe x1, software x1, USB communication cable, manual x1, coupling agent x1, AA (No. 5) battery x2, instrument case x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

MT660

MT660