Mattel MT192 wearable coating ultrasonic Thickness Gauge, suitable for metal/plastic/ceramic/Glass, etc

Mattel MT192 wearable coating ultrasonic Thickness Gauge has a single echo and multi-echo two kinds of plastic parts Measurement mode film thickness Measurement Instrument, can penetrate the coating measurement material thickness, MT192 wearable coating ultrasonic Thickness Gauge with USB interface and backlight display function.

mitech

mitech-

PRUT210 Ultrasonic Thickness Gauge Film thickness range 0.75~ 225mm

Login -

Defelsko PosiTector UTG C1 ultrasonic wall thickness meter for single-sided measurable structures only

$ 1316.00 -

Defelsko PosiTector UTG M1 digital display ultrasonic wall thickness meter, multi-echo probe 2.5~ 125mm range

$ 2171.00 -

KAIRDA N05 Ultrasonic Thickness Gauge Probe

Login -

DUBAN DB22-TM240A Ultrasonic Thickness Gauge 200mm/0.1mm

$ 376.00

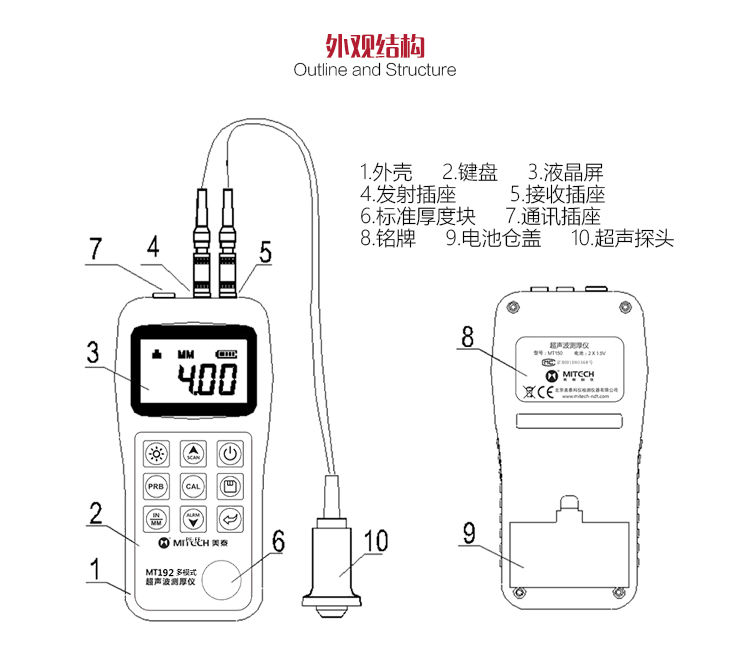

Overview

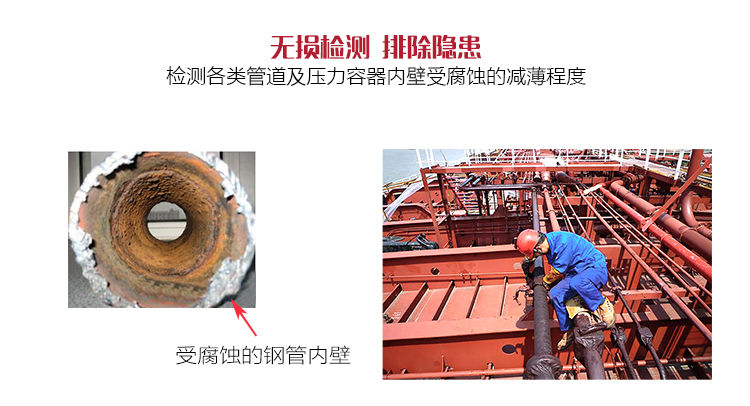

Mattel's MT192 Penetrable Coating Ultrasonic Thickness Gauge is based on the principle of ultrasonic measurement, which can measure the thickness of metals, plastics, ceramics, glass, and other ultrasonic conductor materials, and can also realize the reverse measurement of the sound velocity of materials. Compared with traditional measurement methods, the advantage of ultrasonic Thickness Gauge is that it only needs to touch one side of the workpiece to be measured, and its unique penetrating coating thickness measurement performance provides a more effective solution for the thickness inspection of workpieces coated with paint or anti-corrosion materials, without the need to dispose of the surface coating before measurement, and can be measured directly. It is widely used in the monitoring of the corrosion thinning degree of various pipelines and pressure vessels in production equipment in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields, and can also be used to accurately measure various plates and various processed parts. It is a professional precision instrument required to improve production efficiency and pass rate and save costs.

Functional use

Suitable for measuring the thickness of metals (e.g., steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass, and any other good conductor of ultrasonic waves, there are two modes of thickness measurement: emit-echo mode and echo-echo mode, which can penetrate the coating for thickness measurement without counting the coating thickness

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

Known thicknesses can be used to backmeasure the speed of sound to improve measurement accuracy

It has a coupling status prompt function

There is an EL backlit display, which is convenient for use in low-light environments

There is a residual battery indication function, which can display the remaining battery power in real time

It has power-saving functions such as automatic sleep and automatic shutdown

With USB interface, it can easily and quickly exchange data with a PC

It can be equipped with a variety of dual element transducers with different frequencies and different element sizes

It can be equipped with microcomputer software, which has rich functions such as transmitting measurement results, measuring value storage management, statistical analysis of measured values, and printing measurement reports

Features

Large-capacity storage, low-power design, can be used for more than several months

The known thickness can be used to measure the speed of sound back, which can meet the thickness detection needs of a variety of materials

Equipped with USB data processing software, it can be connected to a computer for data analysis, storage, printing, etc

It can be compatible with a variety of probes with different frequencies and different wafer sizes, and automatically identify different probe types such as high temperature, coarse grain, and small pipe diameter

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

High-precision probes equipped with narrow pulse composite wafers with small blind spots and accurate measurements

There is an EL backlit display, which is convenient for use in low-light environments

It is equipped with power-saving functions such as automatic sleep and automatic shutdown, and the remaining power indication function

Small, portable, and highly reliable, it is suitable for harsh operating environments and is resistant to vibration, shock and electromagnetic interference

mitech MT192 Multimode Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | Emission-echo mode (0.65~ 600) mm (in steel, suitable for probe segmentation); echo-echo mode (3~ 60) mm (in steel, P5EE probe) |

| Probe Frequency | (2.5-7)MHZ |

| Probe diameter | Thickness probe NO5 diameter 10MM, microcrystalline probe N07 diameter 6MM, high temperature probe HT5 diameter 12MM, narrow pulse thickness probe P5EE diameter 10MM, coarse crystal Probe diameter 12MM |

| minimum pipe diameter | Φ15mm×2.0mm |

| Display resolution | 0.1/0.01mm |

| error of indication | +/- 0.05mm (≤ 10mm );( +/- 0.5% H + 0.01) mm (> 10mm); H is the thickness of the measured object |

| Measurement speed | Single point measurement 7 times per second, scanning mode 16 times per second |

| Display | High contrast ratio segment LCD display (support EL backlight display) |

| Speed of sound | 1000~9999m/s |

| Thickness measurement mode | Emission-Echo Mode (P-E) and Echo-Echo Mode (E-E) |

| Probe calibrated | Zero point calibrated, two point calibrated |

| Speed of sound | support |

| display mode | Single point measurement, maximum measurement and difference measurement |

| unit system | Metric (mm) or imperial (inch) |

| Operating language | Chinese |

| Storage Capacity | Can store 20 sets (up to 100 Measured values each) of thickness measurement data |

| Communication interface | USB1.1 |

| data printing | Connect to computer to print |

| Power Supply | 3V (2 AA size alkaline batteries) |

| Power saving method | With automatic screen standby, automatic sleep, automatic shutdown and other power-saving functions |

| Working time | More than 50 hours (when the backlight is not turned on) |

| Environmental requirements | Operating temperature -20 ℃~ + 50 ℃; Storage temperature: -30 ℃~ + 70 ℃ |

| Working Relative Humidity | ≤90% |

| Shell material | ABS engineering plastics |

| Host size | 150*74*32mm |

| Machine Weight | 1.3KG |

| PC software | Yes. |

| voice broadcast data | none |

mitech MT192 Multimode Ultrasonic Thickness Gauge Packing list

Instrument host x1, manual x1, probe x1, coupling agent x1, AA (No. 5) battery x2, instrument case x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

MT192

MT192