IPRE PRCT210N platings Thickness Gauge for measurement of chrome plating on copper

IPRE PRCT210N platings Thickness Gauge is a split eddy current platings thickness Measurement Instrument. Coating thickness detection range is 0~1250μm, and PRCT210N can measure the thickness of chrome plating on copper from 0~40μm.

Ipre

Ipre-

LANDTEK CM8823 film thickness eddy Current Coating Thickness Gauge

$ 261.00 -

AMITTARI AC-112AS Coating Thickness Gauge 5 buttons

$ 348.00 -

QNix 9500Pro Coating Thickness Gauge

$ 1431.00 -

German EPK MikroTest Ni100 McCourt coated platings Thickness Gauge, thickness measurement: 0~100μm

$ 2047.00 -

CHINA CTG-802-1500FV cylindrical coating Thickness Gauge, split iron-based large V type, suitable for surface measurement

$ 230.00

Introduction

1. The eddy current thickness measurement method is used to measure the thickness of the non-conductive covering layer on the non-magnetic metal matrix;

2. Split (the sensor and the instrument are connected by a lead);

3. Unique temperature compensation algorithm;

4. There are two measurement methods: continuous measurement mode (CONTINUE) and single measurement mode (SINGLE);

5. It has statistical functions: average value (MEAN), maximum value (MAX), minimum value (MIN), number of tests (NO.), standard deviation (S.DEV);

6. With storage function: 500 measured values can be stored;

Scope of application

PRCT210N The electroplating Thickness Gauge is widely used in metal processing, chemical industry, commodity inspection, electroplating, spraying, pipeline anti-corrosion, aluminum profile, steel structure and other industries, as well as shipbuilding, aerospace, electric power, pot special inspection, technical supervision bureau and other industries.

Ipre PRCT210N Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Eddy Current |

| Measurement range | 0~1250μm |

| margin of error | ±3% |

| Resolution | 0.1μm|1μm |

| Minimum measurement surface | Φ5mm |

| Minimum radius of curvature | Convex 3mm |

| thinnest substrate | 0.3mm |

| probe | Split probe |

| statistical function | Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| Power Supply | 3 * AAA 1.5V alkaline battery |

| Calibrated Certificate | none |

| system language | Chinese |

| Display screen | LCD screen |

| Data storage | 500 Measured values |

| supporting software | none |

| Machine Weight | 230g |

| Machine size | 155*68*27mm |

| statistical function | Single measurement, continuous measurement |

| Error of indication | One-point calibrated : +/- ( 3% H + 1.5) μm; two-point calibrated : +/- [( 1~ 3) % H + 1.5] μm |

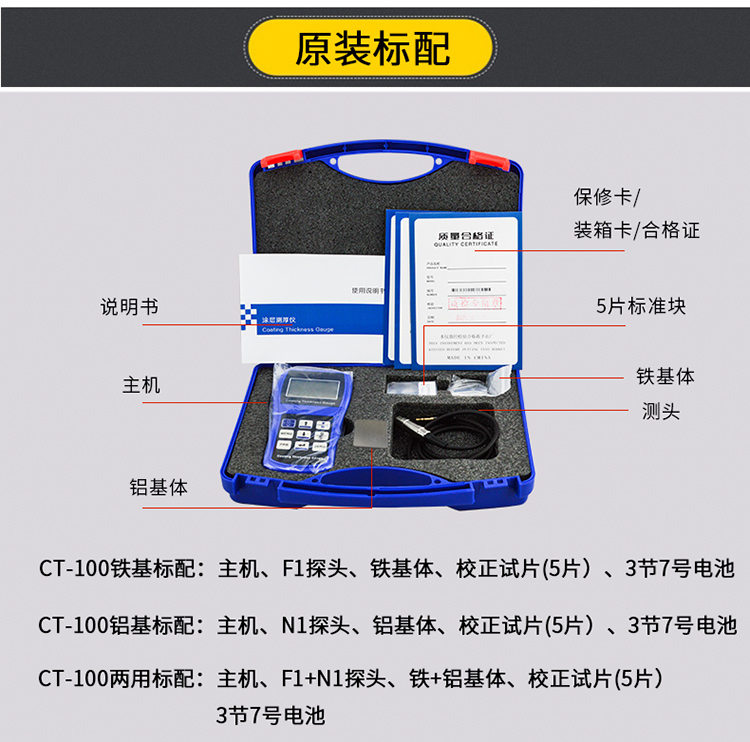

Ipre PRCT210N Coating Thickness Gauge Packing list

host x1, probe x1, standard test piece x1, manual x1, certificate x1, printer x1, base x1, battery x3, warranty card x1, packing list x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveQJ 990.3A-2011

- ActiveASTM B244-2021

- ActiveISO 2360-2017

- ActiveASTM D7091-2022

- ASTM E376-2019

- ActiveHG/T 3885-2006

- ActiveGB/T 13452.2-2008

PRCT210N

PRCT210N