MODERNER LS Falling Sand Abrasion Tester ASTM Standard Organic coating test

The standard shakeout method is used to test the coating abrasion resistance, the length of the duct is 914mm, the inner diameter is 19mm, and the distance of the test plate and the center position of the sand flow can be adjusted to meet the needs of accurate testing.

Moderner

ModernerIntroduction

MODERNER LS falling sand abrasion testing machine is used to test the abrasion resistance of organic coatings under standard conditions. The testing method of the testing machine complies with the American industrial standard ASTM D968-83 for testing the abrasion resistance of organic coatings using the falling sand method. Construction industry industry standard JG/T 133-2000 Requirements for testing the wear resistance of fluorocarbon coatings on aluminum profiles and aluminum plates used in construction. The LS falling sand abrasion testing machine is easy to operate.

Principle

The LS falling sand abrasion testing machine tests the abrasion resistance of the coating by dropping the abrasive from a specified height onto the coated test panel through a conduit until the substrate of the test panel is exposed. The wear resistance of the coating on the test plate is expressed by the amount of wear per unit film thickness.

Specifications

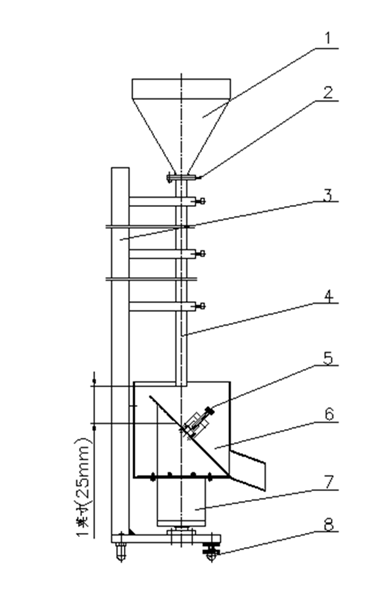

| model | LS |

| structure | Funnel (1), falling sand switch (2), bracket (3), conduit (4), test plate fixture (5), sand box (6), adjusting screw (7) |

| Dimensions | 230mm200mm1500mm (lengthÃwidthÃheight) |

| Catheter length | 36 inches (914mm) |

| Catheter inner diameter | 0.75 inches (19mm) |

| Total Weight | 25kg |

Introduction to appearance and structure

1. The LS falling sand abrasion resistance testing machine is equipped with a switch to control the flow of sand near the conduit. There is a sand box at the bottom of the conduit at an angle of 45 degrees to the vertical position for placing the test plate. There are clamps on both sides of the sand box to clamp the test plate. .

2. There is a height adjustment nut at the bottom of the wear-resistant testing machine, which is used to adjust the distance from the pipe to the painted surface.

3. There are adjustment screws at the bottom of the wear-resistant testing machine to properly adjust the center position of the sand flow.

1ââFunnel 2ââShakeout switch 3ââBracket 4ââConduit

5ââTest plate fixture 6ââSand box 7ââHeight adjustment nut 8ââAdjustment screw

Test preparation

1. Prepare the test plate according to the standard requirements and place it for 24 hours under the conditions of (23±2)℃ and Relative Humidity (50±5)%.

2. Calibrate LS falling sand abrasion testing machine

(1) Pour a certain amount of sand into the funnel, check the sand flow falling from the lower end of the conduit, and calibrate the device with the bottom adjustment screw until the center of the sand bundle falls exactly in the center of the sand flow when viewed from two positions 90° to each other. until the position. Use the height adjustment nut to adjust the distance from the pipe to the painted surface. According to ASTM standards, when measured in the vertical direction, its closest point is 1 inch (25mm). Users need to adjust according to the thickness of their own sample. The machine is pre-adjusted to 25mm at the factory. . Pour a certain volume of sand (2000±10ml is appropriate) and measure the outflow time. The outflow speed should be 2L within 21S to 23.5S.

(2) Fix the test plate with the test plate clamp, and gradually increase the amount of sand added until the base material with a diameter of 5/32 inches (4mm) is gradually worn away. The entire wear area is an oval approximately 1 inch (25mm) wide and 1.25 inches (30mm) long. The center of the maximum wear area should be on the center line of the long axis of the wear pattern and within 9/16 to 11/16 inches (14 to 17mm) of the upper end. In order to correct the wear dot to the center of the wear pattern, the instrument is allowed to make fine adjustments.

(3) Fix a metal test plate with a test plate fixture. There is a 5/32-inch (4mm) small hole on it. The center of the hole needs to be aligned with the center of the conduit. Weigh the amount of sand falling into the container through the test plate hole. If the amount of sand passing through the hole is 90% to 93% of the total amount of sand falling on the test plate, the LS falling sand abrasion Tester is considered standard.

Steps

1. Mark three circular areas on each test panel, each circular area is approximately 1 inch (25mm) in diameter, and allow the test panel to fit properly on the test panel holder of the LS falling sand abrasion Tester. in place. Test the coating thickness according to the standard, with at least three test points in each area, and record the average coating thickness in each area.

2. Fix the coated test panel on the test panel holder with the test panel clamp. Adjust the test panel so that the marked area is just below the center of the conduit. Pour a certain volume of standard sand into the funnel and turn on the shakeout. Switch, let the sand pass through the conduit and hit the test plate. Use a container at the bottom of the LS falling sand abrasion Tester to collect the falling sand. Repeat until a 5/32-inch (4mm) diameter area of ââcoating is exposed to the substrate. During the test, the appropriate increment of sand is 2000±10ml. When approaching the end point, 200±2ml of sand can be added to the funnel.

3. Calculate the wear resistance value of each test area of ââthe painted test panel according to the following formula

A=V/T

In the formula:

AââAbrasion resistance value, in liters per micron

VââThe amount of abrasive used, liters (keep one decimal place)

Tââcoating thickness, micron (keep one decimal place)

It is necessary to calculate the average wear resistance value of different areas of the same test plate and the average wear resistance of different test plates.

Precautions for use

1. In order to ensure that the center of the sand bundle is exactly at the center of the falling sand flow, check the alignment of the conduit at regular intervals.

2. After the sand has passed through the LS falling sand abrasion Tester 25 times, use a No. 30 sieve to remove the finer sand. The sand must be replaced after 50 times.

3. In order to obtain the highest precision test results, the buyer and seller should use sand from the same source.

Moderner LS Falling Sand Abrasion TesterSpecifications

| LIST | VALUE |

|---|---|

| structure | Funnel (1), shakeout switch (2), bracket (3), conduit (4), test plate fixture (5), sandbox (6), adjusting screw (7) |

| Dimensions | 230*200*1500mm |

| Conduit length | 914mm |

| Catheter inner diameter | Ф19mm |

| Machine Weight | 25kg |

Moderner LS Falling Sand Abrasion Tester Packing list

funnel x1, shakeout switch x1, bracket x1, catheter x1, test plate fixture x1, sandbox x1, adjustment screw x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Perovskite film preparatory method

- Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets

- New: Defelsko PosiTest CH cross-cut adhesion Tester

- Application scheme of coating thickness test on wood board [with test video]

- Curved plastic coating thickness test application scheme [with test video]

- PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- Defelsko PosiTector 200 Ultrasonic coating Thickness Gauge Chinese version Instructions for use [2023 new version]

- Appearance evolution of Defelsko coating Thickness Gauge to see the progress of industrial testing instruments

- Defelsko PosiTector 6000 coating Thickness Gauge Chinese version Instructions for use [2023 new version]

- Calibration Terms - Coating Thickness Gages

- ActiveGB/T 23988-2009

- ActiveYS/T 1186-2017

- ActiveGB/T 8013.1-2018

- AbolishGB/T 12967.7-2010

- ActiveASTM D 968-2017

- AbolishJB/T 5364-1991

LS

LS