Pushen 120 line manual Ink Proofer metal anilox roll, quadrangular pyramid mesh shape

Pushen 120 line manual Ink Proofer metal anilox roller anilox line number 120LPI, mesh shape quadrangular pyramid, print width 70mm.

Pushen

Pushen-

CHINA ZS-160 Printing ink manual Ink Proofer 160 lines/inch

$ 179.00 -

Pushen ZS-160 manual Ink Proofer Line Count 160LPI Line Gravure ink Proofing Roller

$ 261.00 -

RK 400 wire metal anilox roller KLOX.14

$ 371.00 -

RK 180 wire metal anilox roller KLOX.12

$ 371.00 -

UK RK KLOX.15 manual Ink Proofer 500 line

$ 1126.00

Introduction

Pushhen 120 line development color wheel metal anilox roller has a rectangular pyramid-shaped mesh cell, which is completed by electronic engraving technology, and is currently widely used. Metal anilox roller, also known as anilox ink transfer roller, is an important part of the ink transfer part of the flexographic plate. 120-line color wheel The number of lines of the metal anilox roller is 120LPI. Chrome plating on the surface of the anilox roller has the advantages of wear resistance and corrosion resistance, and the service life is longer.

Note: The line number of the metal anilox roller is inversely proportional to the wet film thickness, that is, the larger the line number, the smaller the wet film thickness.

Specifications

| model | product name | Number of threads | Cell shape |

| 120 lines | Metal Anilox Roller | 120LPI | Pyramid |

The structure of anilox roller

The anilox roll body is composed of mesh cells and mesh walls. From the perspective of the structure of the anilox roller, it is mainly composed of the roller core, the base material and the surface coating. The plating layer is electroplated copper, which is the basis for making anilox roller mesh cells and mesh walls. The metal anilox roller is coated with metal chrome on the surface, which can improve the wear resistance of the anilox roller and prevent the solvent from corroding the same layer of the base layer.

Process flow of metal anilox roller

Metal roller base - copper plating - engraving - chrome plating

120 line anilox roll details

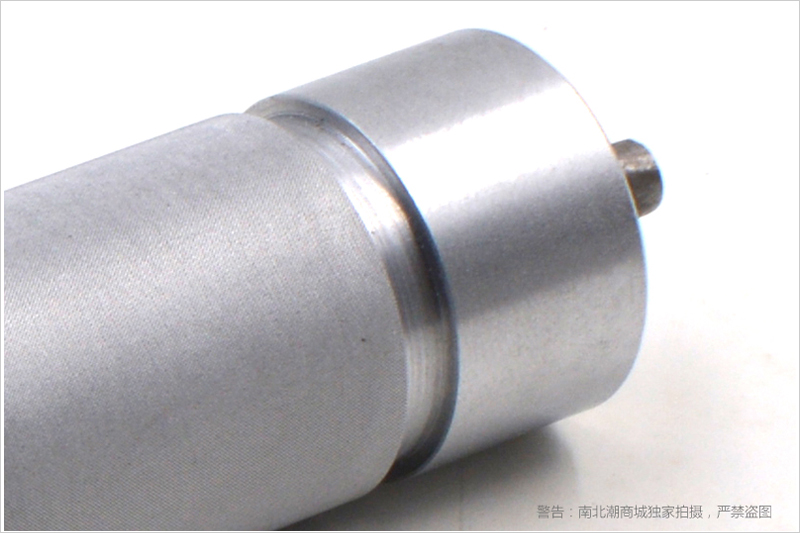

Pushhen 120 line exhibition color wheel metal anilox roller overall picture

Pushhen 120 line color wheel metal anilox roller left side picture

Pushhen 120 line exhibition color wheel metal anilox roller right side picture

Pushhen 120 line color wheel metal anilox roller details 1

Pushhen 120 line color wheel metal anilox roller details 2

Pushhen 120 line exhibition color wheel

Pushen 120 lines Metal reticulated kunSpecifications

| LIST | VALUE |

|---|---|

| Number of reticulated lines | 120LPI |

| Mesh shape | quadrangular pyramid |

| Printing width | 70mm |

Pushen 120 lines Metal reticulated kun Packing list

Manual Ink Proofer Metal Anilox Roller x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

120 lines

120 lines