Pushen KTQ-55mm adjustable Coating Applicator Application width 55mm

Adjustable, wet-film thickness 0~3500μm, Application width 55mm, precision +/- 2μm, material oxidation aluminum, Graduation 10μm.

Pushen

Pushen-

Leneta Form 2C Opacity Chart

$ 309.00

Introduction

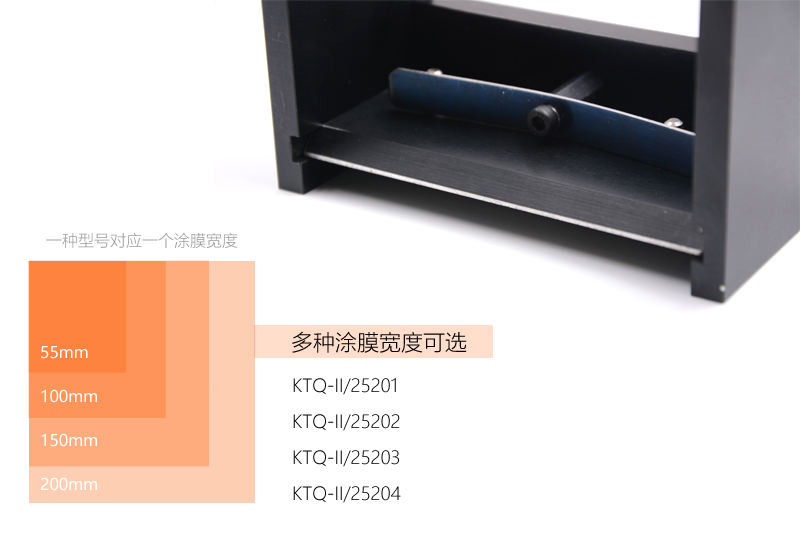

Pushen KTQ-II/25201 Adjustable Coater is an adjustable gap coater, which can be used for uniform film coating on flat substrates. KTQ-II/25201 adjustable coater can coat film thickness range from 0~3500μm, and coating width is 55mm. The adjustable Film Applicator is suitable for precise evaluation studies of small differences in film thickness.

Features

1. KTQ-II/25201 adjustable applicator can be used to achieve uniform film thickness on a flat substrate.

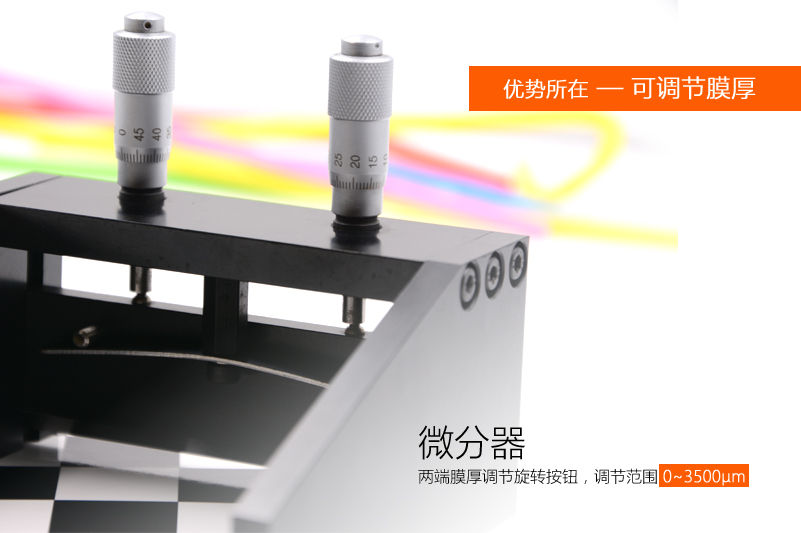

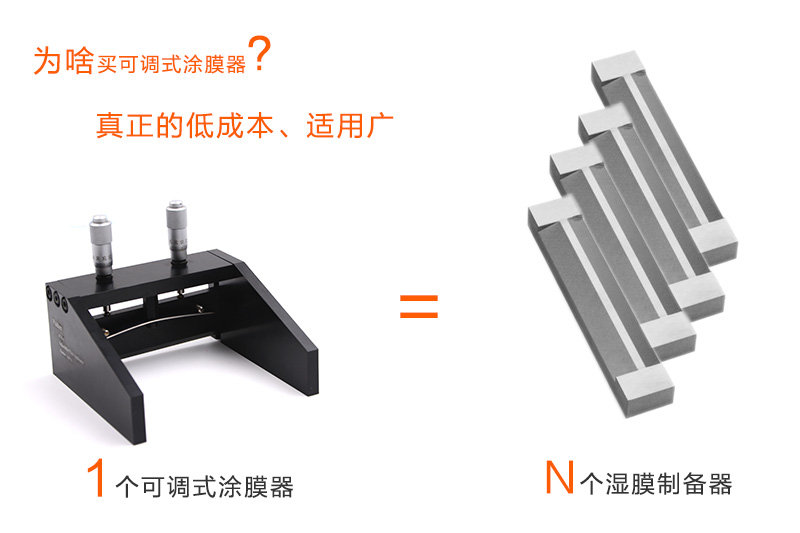

2. The adjustable applicator can reduce the need for various fixed gap applicators, and the scraper gap can be controlled by adjusting the differentiator above.

3. The adjusted gap is between 0 and 3500 microns, and the gap of the scraper is adjusted in units of 10 microns.

4. The KTQ-II/25201 adjustable Film Applicator has extended sides, which can gather the paint during the film coating process, and can manually coat high-concentration and high-viscosity liquids on flat substrates.

operation method

1) Put the KTQ-II/25201 adjustable applicator on a completely flat surface of the test substrate. Adjust scraper to desired gap (should be twice the desired wet film thickness)

2) In front of the coating knife, pour a small amount of test sample between the end plates. At a slow and uniform speed, about 1~2cm/s.

3) Move the applicator over the substrate surface until the liquid is fully coated and any remaining liquid has been removed from the end of the coating path.

4) When coating, use a wet Film Thickness Gauge to measure and adjust the gap until the desired wet film thickness is achieved.

NOTE: The exact ratio of wet film thickness to any applicator knife gap depends on the materials used, the viscosity and texture of the liquid, the force exerted on the applicator knife, the film speed, and the geometry of the film edge.

Adjustable applicator care and maintenance

1) After the KTQ-II/25201 adjustable applicator is used, it should be cleaned with an appropriate solvent immediately.

2) Both ends of the scraper move in the slot, and the slot needs to be kept free of test sample material at all times.

3) The differentiators occasionally need to be repositioned to correct for wear or misalignment. Correction differentiators can be adjusted by loosening (not removing) the concealed set screw on each differentiator to allow the assembly to be lowered or raised.

Pushen KTQ-55mm MicroMeter Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| type | Adjustable |

| WFT | 0 ~ 3500µm |

| Application width | 55mm |

| precision | ± 2μm |

| material | Aluminum oxidation |

| Graduation | 10µm |

Pushen KTQ-55mm MicroMeter Film Applicator Packing list

Film applicator X1, instruction manual x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Combined pencil Hardness Tester operating instructions

- Shanghai Pushen pushen film preparation instrument selection table [selection]

- Pushen KTQ Micrometer Film Applicator

- A good manual Ink Proofer from domestic (CN)

- ActiveGB/T 22374-2018

- ActiveGB/T 1727-2021

- ActiveGB/T 7044-2022

- ActiveHG/T 20720-2020

- ActiveHG/T 3355-2003

- ActiveHG/T 3951-2007

- AbolishGB/T 9755-2014

- AbolishGB/T 11175-2002

- ActiveJB/T 7663.2-2007

- ReplacedGB 1727-1992

KTQ-55mm

KTQ-55mm