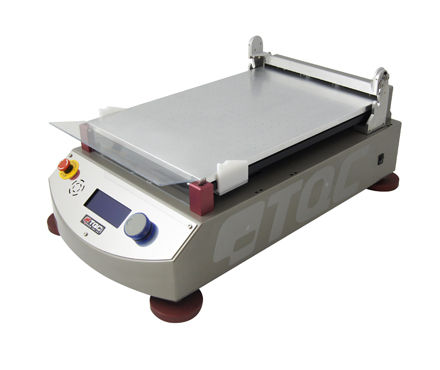

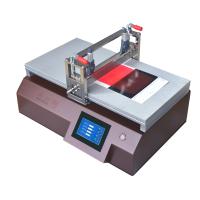

TQC AB3405 Automatic Film Applicator 110V Standard Block Coating Applicator heating porous Vacuum Pump bed

The TQC AB3405 Automatic Film Applicator is a heating Automatic Film Applicator equipped with a heating porous Vacuum Pump bed, AB3405 Automatic Film Applicator, also known as the applicator/Coating Machine, with a wire rod length of up to 325mm and a rocker speed of 2~ 500mm/s.

TQC sheen

TQC sheen-

China TBJ-X3-DJ20 automatic spraying and coating machine bar + Drawdown blade + lame plating + heating + Vacuum chuck + automatic feeding

$ 9544.00 -

HuiNuo TM3200Pro/15 Automatic Film Applicator bar drawdown blade Coater ECA 100 * 70cm

$ 11438.00 -

HuiNuo TM3300/07 Multifunctional miniature Coater (for glove box) Spreader area 21 * 15cm

$ 5124.00 -

HuiNuo TM3200Pro/FJ01 Automatic Film Applicator (with manual unwinding) servo motor, ECA 50 * 45cm

$ 6387.00 -

HuiNuo TM2000Pro/02 drawdown blade Film Applicator Coating size 400 * 300mm

$ 2440.00

Automatic Coating Machine Description

The TQC automatic Film Applicator provides a reliable and basic coating method with excellent repeatability and reproducibility for the coating of paint on test charts, plates or thin sheets, eliminating various instabilities caused by human factors. Changes in speed, pressure, direction, etc., can lead to irregularities in the coating results, which are also affected by the shear force and the weight of the applicator. The TQC automatic film coating machine can well control (eliminate) these variable factors and make them stable. The thickness of the coating film is consistent across the entire plane. The repeatability with the TQC applicator is very good. It can produce many of the same precise coatings in a very short time. The quality of the coating results is very important for studying the rheological properties of the application media. In order to prepare a variety of coating samples for testing the rheological properties, wear resistance, hiding power and viscosity of raw materials, TQC automatic film coating machine is an important helper. Each type of automatic film coating machine can be used for glass, paper, metal substrates and sheets. All automatic models can be used in combination with standard block type applicators, such as bird applicators, Becker applicators, or screw type applicators (wire wound rod – wire bars), which can be selected according to different configuration requirements.

The automatic coating machine is suitable for the industry

Coating laboratory, coating production, surface treatment, powder coating.

Automatic Coating Machine Product Features

Automatic test folders

The test chart is fixed to the coater (when no vacuum Table is installed) and is automatically released at the end of the process. This eliminates two steps in the process, and the operator does not need to turn the machine to access the clamps.

Flat glass bed that is easy to clean

The models of automatic Film Applicators with easy-to-clean flat glass beds are AB3120 and AB3125.

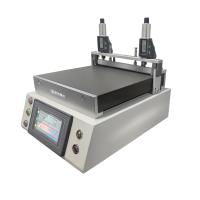

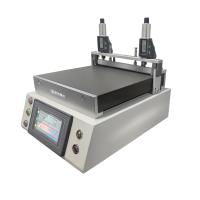

Vacuum bed with Vacuum Pump

The models of automatic Film Applicators for vacuum Tables with Vacuum Pumps are AB3220, AB3225, AB3320 and AB3325.

Equipped with 2 electronically controlled vacuum zones in DIN A3 and DIN A4 sizes.

Only the AB3220 and AB3225 have a vacuum area size of A4.

The removable bed is easy to clean and maintain

The open structure behind the vacuum Table ensures that the vacuum hole can be cleaned at any time.

Automatic scraper applicator storage device

The squeegee applicator rests at the tail of the test chart. After the film is applied, the rocker arm is automatically retracted. Two more steps are eliminated in this process and important coating time is saved.

flexibility

This automatic Film Applicator is suitable for all applicators. The length and speed settings can be adjusted in any way the operator chooses, and there is a common pre-option for quick setup.

Wide range of speeds

The speed range is: 2-500mm/s

Safety precautions for the operator

In addition to an emergency brake button, the automatic applicator is equipped with an intelligent hand Detector that stops when the part of our body is very close to the rocker. The automatic Film Applicator complies with the Machinery Directive 2006/42/EG.

Sturdy support feet

The sturdy feet ensure that the machine works smoothly and prevent external interference.

Menu-driven

Driven by user-friendly multi-language menus, all settings are digital, providing a very intuitive way to operate by using a convenient jog/dial switch. Simple and straightforward, it can be used without an operating manual.

The position of the operator panel is set to save space

The display and buttons are set in the empty square of the lacquer applicator.

illuminating

A 5W warm white LED light is included as standard to illuminate the work area.

mute

The integrated Vacuum Pump of the automatic Film Applicator is fitted with a muffler, which greatly reduces the noise from 81 dBa to 66 dBa. The position of the graph and the position of the vacuum are set to eliminate some of the noise and reduce the noise to 60 dBa.

Application

· Gravure/flexographic presses that test inks and surface coatings.

· Liquid ink manufacturing for testing ink depth/strength and coatings.

· Surface coating, tin sheet printing and picture varnish manufacturing.

· The paper and cardboard industry, which tests the properties of coatings and varnishes on coated paper and cardboard.

· Paints, resins, can coatings, adhesives, dyes, and pigments manufacturing.

· Photographic paper, cosmetics and ceramic coolers. Test fabric prints in shades of color/print.

The automatic film coating machine can coat on a variety of substrates, such as plastic films, paper, gold plate, metal sheets, metal sheets, and textiles, etc.

Automatic Coating Machine Special Care

· Although the design of this instrument is robust, it is a precision instrument and cannot be dropped or struck.

· Clean the instrument after use.

· Use a soft, dry cloth to clean the instrument, not a wire brush or sandpaper. Do not use detergents to clean the instrument as it may cause long-term damage.

· Do not use compressed air to clean the instrument.

Safety protection measures for automatic coating machines

· Not suitable for use in the sun and high light.

· Avoid using in excessively high or low temperature environments.

· Keep dry

· Make sure the instrument is connected to an electrical outlet with a grounding wire.

· When adjusting any electrical components, make sure the instrument is powered off.

Automatic coater model

AB3120 TQC Electric Automatic Film Applicator 230V with glass bed and attachment for standard block coater and screw coater.

AB3220 TQC Electric Automatic Film Applicator 230V with porous vacuum Table for standard block applicator and screw coater, built-in Vacuum Pump and attachments.

AB3320 TQC Electric Automatic Film Applicator 230V with Twin Rail Vacuum Table for Standard Block Applicator and Screw Coater, Built-in Vacuum Pump and Attachments.

AB3125 TQC Electric Automatic Film Applicator 110V with glass bed and attachments for standard block applicator and screw coater.

AB3225 TQC Electric Automatic Film Applicator 110V with porous vacuum Table for standard block applicator and screw coater, built-in Vacuum Pump and attachments.

AB3325 TQC Electric Automatic Film Applicator 110V with Twin Rail Vacuum Table for Standard Block Applicator and Screw Coater, Built-in Vacuum Pump and Attachments.

AB3400 TQC Electric Automatic Film Applicator 230V with Heated Porous Vacuum Table for Standard Block Applicator and Screw Coater, Built-in Vacuum Pump and Attachments.

AB3405 TQC Electric Automatic Film Applicator 110V with Heated Porous Vacuum Table for Standard Block Applicator and Screw Coater, Built-in Vacuum Pump and Attachments.

Specifications of automatic coater

| Rocker speed: | 2 – 500 mm/s |

| Rocker speed accuracy: | +/- 1% of set speed |

| Stroke Length: | 50 – 359 mm |

| Stroke length accuracy: | +/- 2 mm |

| Test Chart Size: | DIN A3 |

| Substrate thickness: | 35mm with coating thickness |

| Maximum length of applicator that can be replaced: | Up to 300mm |

| Maximum height of applicator allowed to be replaced: | Up to 80 mm |

| Wire rod length: | Up to 325 mm, at the point fixed in the spiral zone (364 mm long). |

| Wire rod diameter: | On fixed points, up to Ø 10 mm |

| Maximum Vacuum: | -178 mbar |

| LxWxH: | 650 x 350 x 240 mm |

| Power supply: | 115 – 230 V, 50 - 60 Hz |

| Display: | Blu-ray, image 100 x 35mm, pixels 193x64 |

| Power Consumption: | 80W max |

| Insurance Settings: | Panic button, smart initiation switch, integrated audible alarm |

| Function: | Pivot the shuttle button by rotating/pushing |

| Drawing speed: | 12 stride lengths to choose from, speed from 2-500mm/s, free choice (customized) |

Heatable porous vacuum Table

| Minimum Temperature: | Add 5℃ to the ambient temperature |

| Maximum Temperature: | Ambient temperature plus 100℃ (absolute maximum 140℃) |

| Set the resolution of the temperature: | 1℃ |

| Resolution of the indicative temperature reading: | 0.1℃ |

| Temperature Controller: | individual |

| Power Consumption Heating: | 450W |

| Power supply: | 230V, 50Hz |

Drying Time Recorder

| Drying time range: | 1 minute - 2880 minutes (48 hours) |

| Time Readout Accuracy: | Less than 1% of setup time |

| Maximum Test Length: | 350mm |

| Maximum number that can be tracked: | 8 |

Automatic coater comes as standard

· Electric automatic Film Applicator (one of the types supplied)

· Rubber pads (for paint machines with glass plates only)

· Proof of conformity

· Brochure in English

· Power cord

Optional

TQC sheen AB3405 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating method | Wire rod/drawdown blade |

| Application width | 300mm |

| Spreader trip | 50~359mm |

| Coating speed | 2~500mm/s |

| Vacuum pump configuration | Yes. |

| Heating mode | Porous vacuum bed with heating |

| Heating Temperature range | RT+~140℃ |

| Temperature display Accuracy | 0.1℃ |

| Heating power | 450w |

| Coating rod specification | 300mm×80mm |

| Control mode | knob control |

| Display | Blue light, image 100 * 35mm, pixel 193 * 64 |

| Total power consumption | ≤80W |

| Host Power Supply | 115~230V, 50~60Hz |

| Dimensions | 650*350*240mm |

| Maximum test substrate thickness | 35Mm Coating thickness |

| Maximum length of coating applicator | 300mm |

| Maximum width of coating applicator | 80mm |

| Maximum length of coating rod | 325mm |

| Maximum diameter of coating rod | Φ10mm |

TQC sheen AB3405 Automatic Film Applicator Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.