NIRUN LDV-T2 Digital Viscometer Viscosity Range 10~1000000MPa · s

Digital display, Measurement range 10~1000000mPa · s, Rotor specification SC4-21, 27, 28, 29, Rotor speed 0.1~ 200rpm, reproducibility +/- 0.5% F.S, Measurement accuracy +/- 1% F.S, Power supply Voltage AC100-240V, 50Hz/60Hz, DC17V1.2A, Interface RS232, Temperature range - 1~ 150 ℃, Temperature accuracy +/- 0.1 ℃.

NiRun

NiRun-

Ander DV-79 Digital Viscometer Viscosity Range 1mPa·s~ 1000000mPa·s

$ 962.00 -

HUINUO SNB-3 digital display Rotational Viscometer with a small number of sample adapters

$ 1706.00 -

Fungilab Viscolead Adv R Rotational Viscometer Viscometer 13 million cP

Login -

CNSHP NDJ-8S Digital Rotational Viscometer

$ 495.00 -

NIRUN NTV-P3RV Digital Viscometer Fluid Viscosity Tester 40M mpa.s

$ 5138.00

Introduction

NIRUN LDV-T2 digital display viscometer is a viscosity temperature control integrated machine, which integrates viscosity measurement and precise temperature control in one. It breaks through the existing market that has a constant temperature Water Tank, a viscosity measuring instrument, and a small amount of sample adapter to form a split machine. The all-in-one viscosity measurement system is composed of a small sample adapter (SSR) cylindrical sample sleeve and SC4 rotor, which can perform accurate measurement at a certain shear rate. The sample volume only needs 2 to 16m, and the SC4 rotor has a cylindrical geometry. Can provide very accurate viscosity measurement, and can get accurate shear rate data. The small sample cylinder is easy to load and unload, which brings convenience to the cleaning work. The small-volume sample cylinder is closely connected with the temperature controller, so that the temperature of the sample can be kept very accurately. The stirring action of the rotor, combined with the small sample volume, minimizes sample temperature non-uniformity. The constant temperature time is greatly shortened.

Precise temperature control is very helpful for testing the performance changes of your samples and predicting the behavior of products. Controlling the temperature when measuring the viscosity helps to ensure the accuracy of the experimental results. Since the temperature controller is composed of a semiconductor and a built-in automatic optimization temperature program control, the temperature rise/fall is adjustable, and the temperature control accuracy is ±0.1. Temperature control is operated by DV-T2 data acquisition and program-controlled analysis software, which has good operational performance and flexibility. DV-T2 data acquisition and program-controlled analysis software can do rheological curve analysis.

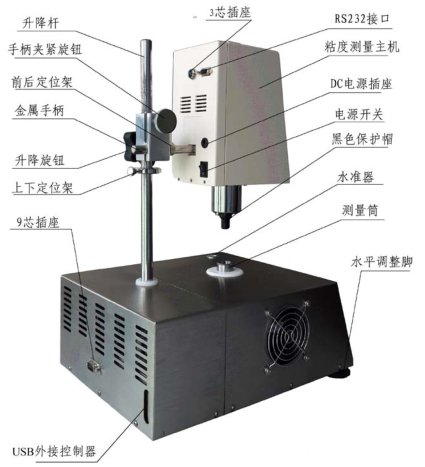

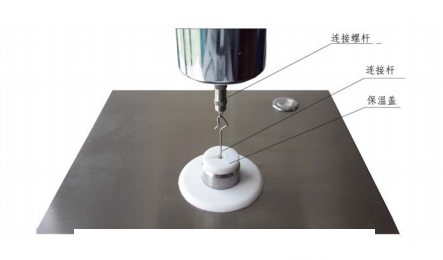

Product Structure

Pictures

Comparison of DV-T2 Viscometer Series Parameters

| model | LDV-T2 | RDV-T2 | HADV-T2 | HBDV-T2 |

| Range mPa·s | 5-1 million | 25-10 million | 50-20 million | 2-80 million |

| Rotor speed | 0.1~200 rpm (continuously variable speed) | |||

| Number of rotors | Standard configuration SC4-21, 27, 28, 29 (optional rotor SC4-14, 15, 16, 18, 25, 31, 34) | |||

| sample size | 2-16ml | |||

| temperature range | -1°C-150°C (temperature control accuracy ±0.1°C) | |||

| repeatability | 0.5% F/S | |||

| measurement accuracy | ±1.0 F/S | |||

NiRun LDV-T2 Digital ViscoMeterSpecifications

| LIST | VALUE |

|---|---|

| Display | digital display |

| Measuring range | 10~1000000mPa·s |

| Rotor Specifications | SC4-21, 27, 28, 29 |

| Rotor speed | 0.1~200rpm |

| Reproducibility | ±0.5%F.S |

| Measurement Accuracy | ±1% |

| Power | AC100-240V,50Hz/60Hz,DC17V1.2A |

| Data Interface | RS232 |

| Temperature range | -1~150℃ |

| temperature Accuracy | ±0.1℃ |

| Encasement material | Five-layer cardboard |

| Collection method | continuous acquisition |

| Capacity | 2~16ml |

| Lifting system | Metal lifting system |

| Bearing system | ruby |

| Torque material | beryllium bronze |

| Control system | microcomputer |

| software system | DV-T2 data collection and programmable analysis software |

| Speed control method | CVT |

NiRun LDV-T2 Digital ViscoMeter Packing list

host x1, rotor x4, manual x1, warranty card x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Methods for Verifying the Accuracy of a Digital Viscometer

- Viscometer Determination Methods of Several Paints

- What is the rheology of paint, how to measure?

- Introduction to performance test of PC surface UV curing organic-inorganic hybrid hardening coatings

- Coating rheology is determined

- National Standard for Coating Viscosity Determination [Rotational Viscometer method]

- what is Viscometer?

- Coating Viscosity Determination Method (Daquan Explanation)

- Viscosity performance of gravure Printing ink

- Two Golden Principles for Effective Viscometer Readings

- ActiveQB/T 2568-2002

- ActiveHG/T 4443-2012

- ActiveHG/T 3323-2008

- ActiveDIN 53017-1993

- ActiveNF EN 12092-2002

- ActiveGB/T 24148.4-2009

- ActiveGB/T 21059-2007

- ActiveGB/T 13217.4-2020

- ActiveHG/T 3948-2007

- ActiveGB/T 12009.3-2009

- ActiveISO 12634-2017

- ActiveJJG 1002-2005

- ActiveGB/T 22427.7-2008

- ActiveGB/T 18856.4-2008

- ActiveSN/T 2903-2011

- ActiveGB/T 17473.5-2008

- ReplacedHG/T 3323-1982

- ActiveSY/T 0522-2008

- ActiveHG/T 3660-1999

- AbolishGB/T 11175-2002

LDV-T2

LDV-T2