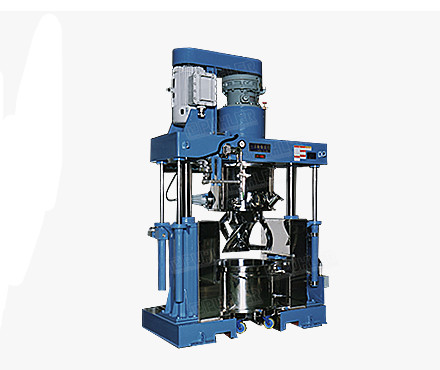

PUHLER Puhler PMK 600 Industrial Stirrer Design Volume 670L

PUHLER Puhler Industrial Stirrer PMK 600 has a barrel volume of 1000x85mm and a lifting stroke of 1000mm. The PMK 600 Industrial Stirrer can choose different Rotation speeds according to different processes and different viscosities.

PUHLER

PUHLER-

HUXI RWD50 Top-in Stir, Three-Blade Impeller Slurry 70mm Rod Length 350mm

$ 565.00 -

HUXI JB90-SH digital display constant speed Overhead Stirrer Four-blade Impeller pulp 50mm Rod length 400mm

$ 392.00 -

SILE Horizontal HD2015W Overhead Stirrer Stirrer 30L/1300rpm

$ 378.00 -

HUXI JB90-SH digital display constant speed Overhead Stirrer Circular six-hole fan blade Impeller blade 50mm Rod length 350mm

$ 389.00 -

HUXI 20030001 Four-blade Impeller (not sold separately)

$ 99.00

Introduction

The PMK Planetary Mixing Kneader is accumulated by a planetary system that drives two rotating cruciform agitators in an overlapping arrangement for effective, gentle product mixing. The high-speed dispersion element combined with the low-speed cross-shaped stirring element through the planetary operation, the precise separation between the stirring paddles and the inner wall of the stirring paddle and the material barrel makes the dead angle extremely small, realizes high energy input, has a strong shear force and a high degree of kneading effect, and achieves an effective mixing-kneading effect.

PAALER PMK Double Planetary Power Hybrid Kneader is an effective, multi-purpose equipment that integrates reaction, mixing, mixing and dispersion. It is suitable for the production process of liquid-liquid, solid-liquid, paste-paste, powder-paste material density and proportion, from low viscosity to high viscosity (1.5 million Cps) in various industries.

Features

1. The (trapezoidal) soft seal between the mechanical seal and the kettle body makes the material can be operated under vacuum;

2. The kettle body can be heated by electricity, steam, water and oil. The unique temperature detection device on the transmission shaft ensures that the temperature error of the material is less than ±1°C, and the jacket, bottom jacket, inner coil and deflector can be cooled;

3. The inner wall of the kettle is finished by a large vertical lathe, and then automatically polished by a large polishing machine to ensure that the movable scraper (suitable for sealant) on the planetary carrier completely scrapes off the material on the inner wall of the kettle when it rotates;

4. The twist frame stirring paddle in the kettle (the distance between the paddle and the paddle, the paddle and the barrel wall is 3-4mm), which rotates at the same time as the revolution, so that the material flows up and down and around, so that the mixing (mixing) effect can be achieved in a very short time. The other one or two high-number dispersers in the kettle rotate at high speed while revolving, so that various materials are strongly sheared and dispersed and mixed, and the effect is several times that of ordinary mixers;

5. The revolution and rotation of the stirring paddle and the high-speed disperser in the kettle are all frequency conversion speed regulation (frequency conversion motor), and different speeds can be selected according to different processes and different viscosities. The speed measurement system directly gives the speed of the different impellers at that time.

Applications

1. Energy:

All kinds of battery pastes and pastes (lithium batteries, nickel-chromium batteries, nickel-metal hydride batteries, fuel cells, power batteries, button batteries, etc.);

2. Electronic appliances:

Electronic electrode paste, ceramic paste, magnetic material, silicone ink, electronic coating, electronic adhesive, electronic device pottingglue, PVC plastic, hot melt adhesive, various pastes;

3. Chemicals:

All kinds of sealants, adhesives (silicone sealants, polysulfide sealants, polyurethane sealants, insulating glass sealants, waterproof sealantsSealant, structural sealant, anaerobic adhesive, stone glue, mold glue, etc.), synthetic resin rubber, silicone oil, pigment, coating, oilInk, putty, abrasives (pastes), lubricating pastes, wax products, synthetic rubber, synthetic resins, various powder materials, ceramic pigmentsMaterial;

Fourth, medical * products:

All kinds of soft ointments, polymer gels (medical patches, pediatric antipyretic patches, cold patches, ice patches, eye patches), capsules, syrup,dental products;

5. Cosmetics and daily chemicals:

Moisturizers, lipsticks, lotions, gels, masks, mascaras, foundations, nail polishes, toothpaste, soaps, shampoos.

Parameters

PUHLER PMK 600 Industrial StirrerSpecifications

| LIST | VALUE |

|---|---|

| output power | 30~37KW |

| Speed range | 0~42rpm |

| Size in barrel | 1000*850mm |

| Barrel Volume | 670L |

| Lifting stroke | 1000mm |

| Dimensions | 2600*1100*3600mm |

| Machine Weight | 4500kg |

PUHLER PMK 600 Industrial Stirrer Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle and Application of Finger Double Planet Stirrer

- Water-based paint production process

- Diatom mud formula and production process

- Preparation method of water-resistant putty powder

- Introduction of emulsion paint production process and production method