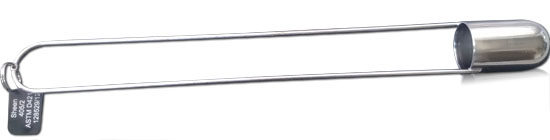

Sheen Ref. 405/5 Zahn Cup ASTM D4212/D1084

Bottom of the warehouse, half price.

SHEEN

SHEEN-

TQC Sheen VF2068 thermostat TM2, temperature control jacket for ISO and AFNOR Viscosity Cups

$ 1259.00 -

British Sheen Ref. 402/4 Viscosity Cup hard brass, standard palin cup, viscosity range 2000-15000

$ 245.00 -

QNB ISO Flow Cup set YONGLIDA contains 3, 4 and 6 Flow Cups

$ 233.00 -

TRUIT TR 1009 Iwata Cup NK-2 Cup, Copper Nickel Plated Material

$ 97.00 -

TQC VF2025 Viscosity Cup filter, stainless steel 5mm

$ 152.00

Viscosity cup principle

Viscosity cups, also known as Zion cups, were originally designed for rapid viscosity and consistency evaluation of products with Newtonian or near-Newtonian properties, providing a high degree of accuracy and repeatability depending on production quality. According to their early forms, although somewhat simple in design, today's Viscosity Cups are produced according to a number of international standards that have been developed over the years and specify not only the precise dimensional tolerances required in the process, but also their use and records of data obtained.

Based on our established experience in manufacturing these types of products, Xinying manufactures Viscosity Cups that provide outstanding testing quality. These Viscosity Cups are produced from selected high-grade materials, using the latest computerized machining technology, and under strict quality management conditions. Smooth, bright surface decoration makes the product easy to use and clean, ensuring a long working life. All our paint Viscosity Cups comply with relevant national standards, and Viscosity Cups with calibration certificates can be ordered separately.

To ensure higher accuracy in your test results, it is highly recommended to calibrate your Viscosity Cup regularly, either through our own calibration department or using our standardized calibration oils.

main feature

Production using high-precision computerized machining

Mirror polished and smooth surface treatment for high flow accuracy and easy maintenance

Strict quality and compliance checks

Note:

Clamp Viscosity Cup holder not included, see optional accessories

Calibration certificate not included, should be specified when booking, see optional accessories

Viscosity Cup Unit

The unit of kinematic viscosity is Stokes, which is Stokes, or Stoke for short. When the dynamic viscosity of a fluid is 1 poise and the density is 1g/cm3, the kinematic viscosity is 1 stokes. cSt is the abbreviation of Centistokes, which means centistokes, which is one hundredth of 1 stoke. Centistokes (cst) is the smallest unit of kinematic viscosity.

Instructions

1. Use appropriate solvent to wipe clean before and after use.ã

2. Select the appropriate Viscosity Cup model to control the outflow time between 20 and 80 seconds. (Different brands and cup sizes have different discharge times, please confirm carefully)

3. Immerse the cup body in the container for 1 to 5 minutes to allow the cup body to reach thermal equilibrium. Lift the cup body vertically from the raw material. The movement needs to be fast and smooth.

Timing begins when the upper end of the cup leaves the liquid surface. When the liquid flows out, the cup body should be kept vertical, and the distance from the liquid surface should not exceed 150mm.

Stop timing when the first breakpoint occurs, and the number of seconds of outflow time represents a certain viscosity value. The difference between the two measured values ââshould be less than 5% of the average value.

Precautions for use

In order to ensure accurate measurement results, it is recommended to purchase at least 1 standard Viscosity Cup with a calibration certificate. By comparing the results of measuring the product standard product sample with the measuring Viscosity Cup and the standard Viscosity Cup, a correction chart is drawn, so that the outflow time can be corrected through the chart to obtain correct test results.

The Viscosity Cup has a short channel length (i.e. cup wall material), so any change in the channel will have a significant impact on the outflow time. Therefore, you need to use appropriate fine brushes and solvents to clean the Viscosity Cup. Do not use other cleaning methods or cleaning tools that may cause scratches.

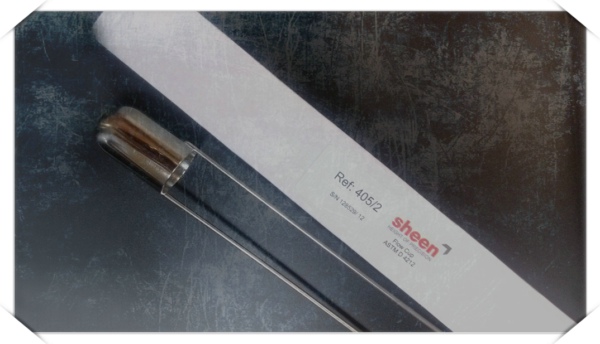

Product actual pictures

Related Desktop Viscosity Cups

No. 417/4 coating Viscosity Cup imported No. 406/4 Ford cup

Viscosity related knowledge

Flow characteristics

In the field of coatings, as well as in many other industries that produce liquid or non-solid materials, new and rapidly developing markets and needs have led to the development of new innovative products.

Therefore, many of these products are currently produced using complex formulas of raw materials and processes, making the quality better and better. For this reason, the control of viscosity becomes more complex, among many important material properties that need to be considered.

In order to meet this stringent production requirement and continuously obtain such high-performance products, it is necessary to use highly accurate testing technology in R&D, production and quality management. Therefore, the demand for viscosity testing has given rise to the birth of products such as Viscosity Cups. Since the price of Viscosity Cups is much cheaper than viscometer instruments, many viscosity tests are performed using Viscosity Cups.

fluid properties

In rheological science, viscosity measurements play a key role in understanding the flow properties of materials and their response to some applied stress. Referring to the basic Newtonian model, when shear forces act on a fluid, the fluid deforms so that layers of material move according to velocity steps related to the applied force. Viscosity is therefore a function of shear force versus shear rate, which depends on the nature of the product.

Because some products are shear dependent, fluid properties must be considered when dealing with viscosity measurements. SHEEN Viscosity Cups are specially designed to detect such fluids, and after continuous improvement, SHEEN Viscosity Cups are more accurate and durable than ordinary domestic (CN) Viscosity Cups.

Fluids that conform to Newtonian mechanical properties and fluids that do not conform to Newtonian mechanical properties

The viscosity of "Newtonian" products, such as water and some oils, is constant at a given temperature regardless of applied shear, while the viscosity of "non-Newtonian" products occurs when shear is applied. When it changes, the viscosity changes.

This property can lead to a dilution effect where deformation causes a decrease in viscosity, or correspondingly an increase in thickness where the viscosity increases.

Thixotropy and antirheology

In fact, most modern coating systems or similar products exhibit some degree of shear-related viscosity drop, a property that is often desirable, for example when these materials are shaken, applied or sprayed.

Lack of control over this characteristic can cause undesirable effects such as inconsistent performance, poor flatness, or sagging.

Commonly encountered fluids that rely on shear include pseudoplastic, plastic, or thixotropic behavior.

The structural properties of many products reduce their viscosities to different equilibrium values ââover a period of time after changing shear, depending on their initial sol-gel shape, and return to their original values ââwhen the shear behavior ceases. Some other products can flow beyond their yield value when sufficient force is applied.

In contrast to the anti-rheological effect, which shows an increase in viscosity under shear, this property is occasionally used in some process procedures, such as grinding, or dispersing.

Comparison of parameters between Dutch TQC Zhaien Cup and SHEEN Zhaien Cup

SHEEN Ref.405/5 Zahn CupSpecifications

| LIST | VALUE |

|---|---|

| Viscosity range | 400~1800cSt |

| outflow time | 20~80s |

| flow hole diameter | 5.41mm |

| Cup body material | stainless steel |

| Filter material | stainless steel |

| Handle material | stainless steel |

| Applicable standards | ASTM D4212/D1084 |

| Certificate | without |

SHEEN Ref.405/5 Zahn Cup Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Sheen and TQC full range of Coating testing instruments alternative comparison table

- How is Architectural coatings Viscosity measured?

- TQC Micrometer Film Applicator Operation Manual

- Comparison of two imported Ford viscosity cups of Sheen and TQC

- Comparison of the world's high-quality brands British SHEEN and Dutch TQC: Scraper Fineness Meter

- British sheen and Dutch TQC brands compared to the Zain Cup

- Sheen Ref. 417/6 Viscosity cup

- A set of pictures of Sheen 402/A25 Viscosity cup

- UK Sheen Ref. 157/60/SO Small Hole Gloss Meter Operating Instructions

- Introduction to performance test of PC surface UV curing organic-inorganic hybrid hardening coatings

Ref.405/5

Ref.405/5