With the development of materials science and engineering technology, PET (polyethylene terephthalate) film is widely used in packaging, electronics and optics. In order to enhance the specific properties of PET film, such as mechanical strength, thermal stability, barrier properties, etc., epoxy resin is usually coated on its surface. This composite combines the excellent properties of PET film and epoxy resin, making it a good choice for many high-performance applications. However, before it can be applied in practice, a series of performance tests are required to ensure its reliability and stability in a variety of usage environments. This article will introduce in detail the main performance test methods of PET film after coating with epoxy resin.

1. Adhesion test

Adhesion is a key index to evaluate the bond strength between epoxy resin coating and PET film, which directly affects the durability and stability of the coating. Adhesion tests include tensile bond strength and scratch tests.

Among them, tensile bond strength is adoptedTensile testing machine, the specific test method is:The coated sample is fixed on a Tensile Testing Machine and a tensile force is gradually applied until the coating separates from the substrate. Measure the force required for peeling, usually expressed in Newtons (N). Standard methods such as ASTM D4541.

In addition, paint film is used for the scratch testScratch knife, tape.

Here's how to do this: Draw a grid pattern (usually 6x6 or 11x11 squares) on the surface of the coating, then tape it to the grid and quickly peel it off. Observe coating peeling and evaluate adhesion levels according to ASTM D3359.

2. Mechanical performance test

Mechanical property tests mainly include tensile strength, elongation and abrasion resistance, which are able to evaluate the durability and reliability of coated PET film in real-world use.

First of all, tensile strength and elongation are employedTensile testing machine, specific inspectionMethods: According to ASTM D882, the coated film was subjected to tensile test. The maximum stress (tensile strength) and the amount of deformation at fracture (elongation) are measured to evaluate the effect of the coating on the mechanical properties of the film.

Furthermore, abrasion resistance is employedTaber abrasion Tester. The detection method is:In accordance with ASTM D4060, the abrasion resistance of coatings is measured by a rotational abrasion test. This is done by placing the sample on a rotating grinding disc and applying a load to measure the mass loss or change in coating thickness after a certain wear cycle.

3. Thermal performance test

Thermal performance testing is used to evaluate the stability and performance changes of coatings under different temperature conditions, mainly including thermal stability and thermal expansion coefficient tests.

First, thermal stability is adoptedThermogravimetric Analyzer (TGA), Differential Scanning Calorimetry (DSC).

Test Method: In accordance with ASTM E1131 (TGA) and ASTM E1356 (DSC) standards, the mass change and heat flow change of the coating during the heating process are measured. TGA is used to evaluate the thermal decomposition temperature and thermal stability of materials, while DSC is used to measure the thermal properties of coatings, such as glass transition temperature and melting temperature.

Second, the coefficient of thermal expansion is adoptedThermomechanical analyzers (TMA).

Inspection Method: Measure the dimensional change of the coating under temperature change to evaluate its coefficient of thermal expansion. The stability of the coating in the environment of temperature fluctuations is evaluated by heating or cooling the sample, recording its dimensional changes, and calculating the coefficient of thermal expansion.

4. Optical performance test

For some special applications, such as optics and transparent packaging materials, the optical properties after coating are critical. The main tests include light transmittance, haze, color, and transparency.

Among them, light transmittance and haze are used separatelySpectrophotometer, haze meter.In accordance with ASTM D1003, the light transmittance and haze of coated films are measured. Light transmittance indicates the ability of a material to transmit visible light, while haze evaluates the degree of scattered transmitted light, affecting the transparency of the material.

In addition, color and transparency are adoptedColorimeter. MostlyMeasure the color change and transparency of the film before and after application. The Colorimeter records the reflection or transmission spectrum of the sample under different light sources, calculates the color difference value, and evaluates the effect of the coating on the optical properties of the film.

5. Chemical resistance test

Chemical resistance tests are used to evaluate the stability of coatings in different chemical environments, mainly including solvent resistance and acid and alkali resistance tests.

Among them, solvent resistance is adoptedSolvent immersion device.The coated film is soaked in different chemical solvents, such as ethanol, toluene, etc., and the changes in the coating are observed. The solvent resistance of a coating is usually evaluated by measuring parameters such as weight changes, surface topography changes, etc.

In addition, acid and alkali resistance is adoptedAcid and alkali solution, soaking device.The coated film is soaked in a specific concentration of acid and alkali solution to observe the stability of the coating. The acid-base resistance of the sample is evaluated by measuring the weight change and mechanical property change in the acid-base environment.

6. Electrical performance test

Electrical performance testing is important for applications that require electrical insulation, including dielectric constant, dielectric loss, volume resistivity, and surface resistivity.

The dielectric constant and dielectric loss are used for detectionLCR bridge,In accordance with ASTM D150, the dielectric constant and dielectric loss of coatings at different frequencies are measured. The dielectric constant indicates the capacitive properties of the material, while the dielectric loss evaluates the electrical energy loss of the material.

Whereas volume resistivity and surface resistivity detection are usedResistance Measuring Instrument.In accordance with ASTM D257, the volume resistivity and surface resistivity of coatings are measured. Volume resistivity indicates the electrical resistance properties inside a material, while surface resistivity evaluates the electrical insulation properties of the material's surface.

7. Weather resistance test

The weather resistance test is used to evaluate the aging performance of the coating in the natural environment, mainly including the ultraviolet aging test and the damp heat aging test.

The ultraviolet aging test is of course adoptedUltraviolet aging Test Chamber. PassSimulate the effect of ultraviolet rays in sunlight on the coating. Through a period of ultraviolet exposure, the aging of the coating, such as discoloration and cracking, is observed, and its weather resistance is evaluated.

In addition, high-low temperatures are used for damp heat aging testsAlternating heat and humidity Test Chamber.The aging test is carried out in a high temperature and high humidity environment to observe the changes in the coating. The resistance to damp heat aging is usually evaluated by measuring the mechanical properties, appearance changes and other parameters of the sample before and after aging.

8. Barrier performance test

The barrier performance test is used to evaluate the barrier ability of the coating against gas and water vapor, mainly including gas transmission rate and water vapor transmission rate test.

First of all, the gas permeability rate is adoptedGas Transmission Rate Tester.In accordance with ASTM D3985, the barrier properties of coatings against gases such as oxygen and carbon dioxide are measured. The barrier properties of the gas are evaluated by testing the rate at which the gas passes through the coating at a certain pressure.

In addition, the water vapor transmission rate is adoptedWater vapor transmittance Tester.In accordance with ASTM E96, the coating is evaluated for its water vapor barrier effect. The transmittance is calculated by measuring the amount of water vapor passing through the coating over a certain period of time.

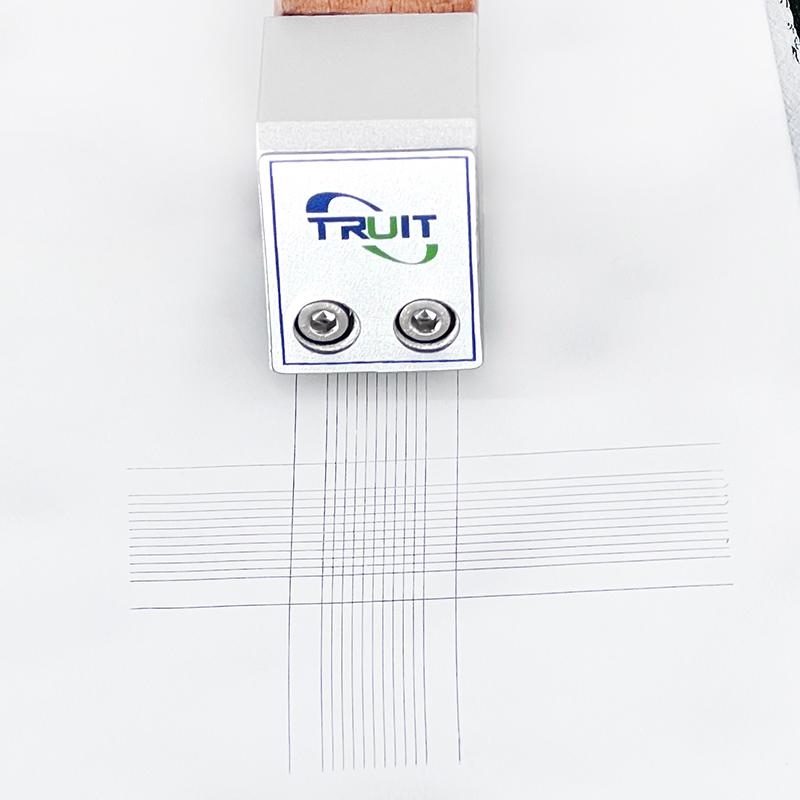

Applicable Film Applicators

On the one hand, the vacuum adsorption function can be well fixed to fix the PET film, and the epoxy resin viscosity is larger, and the scraper scraping can be used to avoid scratches and other conditions.

conclusion

Coating epoxy resin on PET film is an effective way to enhance the properties of the material, and through the above test methods, the properties of the coating can be systematically evaluated to ensure its reliability and stability in practical applications. These tests not only help engineers and scientists understand the basic properties of coatings, but also provide an important basis for the development and application of new materials.