$47432.00

SE

CHINA NBC-DJ4-JPJC-200 Immersion crystallization Coater Roll-to-Roll Film Applicator

Immersion type crystallization coater, roll-to-roll mode, continuous solution pool, crystallization (or adhesion) under specific conditions of substrate, width 200mm, hot Air Oven drying at 130 ℃.

$47432.00

SE

CHINA Rjy-01/200dc Immersion Crystallization Coater Continuous Film Applicator

Immersion type crystallization coater, roll-to-roll mode, continuous solution pool, crystallization (or adhesion) under specific conditions of substrate, width 200mm, hot Air Oven drying at 130 ℃.

$31646.00

SE

Factory Direct Rjy-00/1000 immersion type Coater dip coating double roll extrusion equipment, effective width 1000mm

Unwinding → dip coating → double roll extrusion → winding

Using immersion coating method, equipped with built-in circulation system, Spreader thickness 0.3-10 mm adjustable, mechanical speed 0.1-1 m/min adjustable, double roll extrusion to ensure uniform Spreader.

Login

CHINA Automatic immersion coil Coater Rjy-01/500dc double roll extrusion

Dip coating, suitable for drum substrate Spreader production winding equipment, effective application width 500mm, double roll to roll structure, external infrared heating.

$28488.00

SE

CHINA immersion coil drying air-cooled slitting machine Rdc-01/500clcs dip coating machine

Dip coating, the process is: unwinding → dipping → drying → chilling down → correction → traction → cross-cutting, effective application width 500mm, melamine dipped paper experiment.

$39539.00

SE

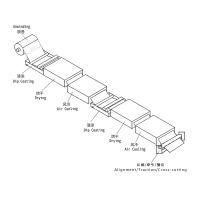

CHINA immersion coil drying air-cooled slitting machine Rdc-02/500clcs dip coating machine

Dip coating, the process is: unwinding → 1 dipping → 1 drying → 1 chilling down → 2 dipping → 2 drying → 2 chilling down → correction → traction → cross-cutting, effective application width 500mm, special for melamine dipping paper experiment.

$34803.00

SE

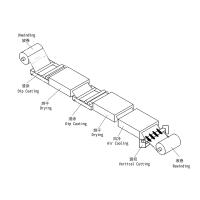

CHINA immersion coil drying air-cooled slitting machine Rdc-01/500cs dipping coating machine

Dip coating, unwinding → first dip coating → drying → second dip coating → drying → air-cooled → vertical cutting → winding, effective application width 500mm, special for melamine dipped paper experiment.

$28488.00

SE

Coil Coater Rjy-00/800 Spreader 800mm double roll extrusion

Unwinding → dip coating → double roll extrusion → pull out platform

Dip coating, suitable for Spreader production and winding equipment for drum substrates, effective application width 800mm, double roll to roll structure

$23752.00

SE

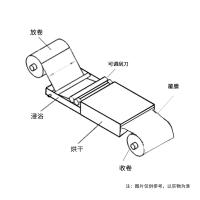

Factory Direct Rgdc- 01.2/400 immersion coil Coater application width 400mm

Rolling → soaking → scraping → drying → film laminating → winding

Spreader process unwinding → soaking → scraping → drying → film laminating → winding, Spreader method soaking + scraping, Coating speed 0.1~ 200mm/min (adjustable), Coating size ≤ 400mm, guide roller width 400mm, film accuracy +/- 5%, Graduation 0.001mm.

$47432.00

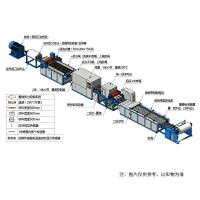

Factory Direct Rdh2-03/500 immersion coil Coater double comma drawdown blade three temperature zone drying

The equipment adopts double comma drawdown blade Spreader head and bath design, Spreader wet thickness range of 0.1~ 3mm, drying temperature up to 250 ℃, integrated three independent temperature zone drying system, to achieve full automation process.

$39539.00

SE

Rgd-300TS Double-sided Coil Film Applicator Guide Roller Width 300mm oven length 1m

Coating thickness dry weight 5um, material width range 210mm, travel speed 0-5m/min, guide roller width 300mm, oven length 1m, stroke +/- 150mm, accuracy +/- 0.5mm.

$39539.00

SE

Taigang Rgd-300TS Double-sided Coil Film Applicator Guide Roller Width 300mm oven length 1m

Coating thickness dry weight 5um, material width range 210mm, travel speed 0-5m/min, guide roller width 300mm, oven length 1m, stroke +/- 150mm, accuracy +/- 0.5mm.

$28488.00

Factory direct sales Rgdjy-02/350dcpro immersion coil Automatic Film Applicator wet film thickness 0.005-3mm Continuous experimental Automatic Film Applicator

Unwinding and scraping → Extruding Dampener Roller and Gel Tank Cleaning 1 → Cleaning 2-Air Knife → Oven 2 meters → Deviation correction → Winding

With unwinding, scraping, soaking, drying, winding continuous functions, wet film thickness adjustment range of 0.005-3mm, Spreader accuracy +/- 5%, using servo drive and PLC control to achieve automatic constant tension and automatic deviation correction, suitable for a variety of coils and coating types.

If you don't know how to choose "Roll-to-Roll Coater", please consult customer service.