KAIRDA NDT320 Ultrasonic Thickness Gauge thickness measurement for hulls, pipes, high Voltage vessels, boilers, plastics, etc

Measurement range 0.75~ 300mm, probe Frequency: 5MHz, measurement error +/- (1% H + 0.04) mm, Display resolution 0.1mm /0.01mm optional, can be equipped with different Frequency he wafer size bimorph probe measurement of different thickness range of materials, with coupling status prompt function, can measure the known thickness of Speed of sound, improve measurement Accuracy.

KairDa

KairDa-

Non-destructive Thickness Gauge DC-2000C Deguang electronic measurement of metal materials and other Film thickness

$ 685.00 -

LANDTEK TM8811 Ultrasonic Thickness Gauge Suitable for metal, ceramic, hard Rubber & plastics, Glass and other hard materials

$ 306.00 -

Linshang LS212 Professional Ultrasonic Thickness Gauge Thickness Measurement 0.8~ 350mm

$ 275.00 -

LANDTEK TM8816 Ultrasonic Thickness Gauge Suitable for Petroleum, Shipbuilding, Machine Manufacturing and Pressure Vessel, Chemical Equipment Boiler, etc

$ 345.00 -

DONGRU DR87S Penetrating coating Ultrasonic Thickness Gauge

$ 447.00

Introduction

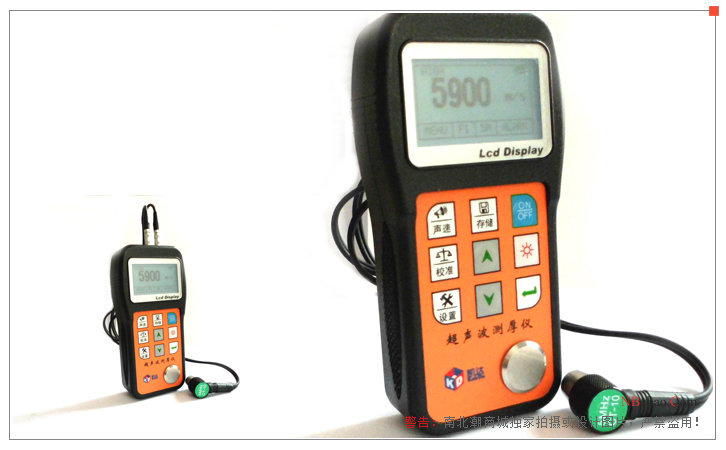

KAIDA NDT320 Ultrasonic Thickness Gauge adds communication function on the basis of standard NDT310 Ultrasonic Thickness Gauge. It can exchange data by connecting to PC and has printing function. NDT320 Ultrasonic Thickness Gauge can also be equipped with dual crystal probes of different frequencies and chip sizes to measure materials with different thickness ranges. It has a coupling status prompt function, which can reversely measure the sound velocity of a known thickness and improve the measurement accuracy.

Features

1. It has the function of prompting the coupling status.

2. NDT320 ultrasonic Thickness Gauge has LED backlight display function, which is convenient for use in dimly lit environments.

3. There is a remaining power indicator function, which can display the remaining battery power in real time.

4. It can be equipped with a variety of dual-crystal probes with different frequencies and different chip sizes to measure thicknesses in different ranges.

5. NDT320 ultrasonic Thickness Gauge has probe zero point calibration and two point calibration functions, which can automatically correct system errors.

6. Knowing the thickness can reverse the sound velocity to improve the measurement accuracy.

7. It has power-saving functions such as automatic sleep and automatic shutdown.

8. Background data processing function; PC communication function; printing function.

9. Small size, portable, high measurement reliability, suitable for harsh operating environments, resistant to vibration, shock and electromagnetic interference.

Application

NDT320 Ultrasonic Thickness Gauge is suitable for measuring the wall thickness of high-pressure vessels, ship hulls, oil and gas pipelines, boilers, etc. Material.

Pictures

KairDa NDT320 Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measuring range | 0.75~ 300mm (probe determined) |

| Probe frequency | 5MHz |

| Probe style | Split probe |

| Probe diameter | F4mm |

| Probe contact temperature | -10~60℃ |

| Lower limit of pipe measurement | F20 * 3mm |

| Measurement error | ±(1%H+0.04)mm |

| Display resolution | 0.1mm /0.01mm optional |

| unit system | mm/inch |

| Storage Capacity | 500 pieces |

| Sound speed range | 1000~9999m/s |

| Display | LCD |

| Operating language | Chinese |

| Data Interface | RS232 |

| Application software | without |

| Power | AA type alkalinity battery 1.5V (2 *) |

| Operating Time | 250H (without backlight) |

| Host size | 150*74*32mm |

| Weight | 238g |

| Application | Measurement of wall thickness of high pressure vessels, hulls, oil and gas pipelines, boilers, etc., and film thickness of various plates. The measured material can be a metal material represented by steel, or a non-metallic material such as plastic and nylon. |

| Error of indication | Not more than ± 0.1 mm |

| Calibrating block | 4.0 mm (steel) |

| Probe diameter | Φ6 mm (optional) Φ10 mm (optional) Φ12 mm (optional) |

| Optional probe | 2MHz (cast iron probe), 7MHz (micro-diameter probe) (Φ15 mm × 2.0 mm), 5MHz (high temperature probe) |

KairDa NDT320 Ultrasonic Thickness Gauge Packing list

Host x1, probe x1, 4.0 mm steel calibrating block x1, coupler x1, battery x2

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveJJF 1224-2009

- ActiveJJF 1126-2004

- ActiveJB/T 11604-2013

- ASTM E797-2021

- AbolishGB/T 11344-2008

- JJF 1126-2004

- AbolishZB N 77001-1989

NDT320

NDT320