LABO 16032 Cardboard Burst Tester 20~6000kPa

Range 20~6000kPa, hydraulic speed 170 ± 15ml/min, suitable for corrugated Cardboard, cardboard, Textile products and materials with high bursting resistance.

Labo

Labo-

Patek Jushi LY-8502 Cardboard Automatic Burst Strength Tester

$ 829.00 -

CHINA NBC-8502B automatic breaking Strength Tester, touch screen breaking machine

$ 1077.00 -

FARI FR-1311 Automatic Cracking Strength Tester

$ 1492.00 -

Essence LD - NP-CMP Cardboard Burst Strength Tester, Vertical Touch Screen Version

$ 1077.00 -

PUYUN PY-H602B Automatic Burst Strength Tester (paper type) ≤ 1600Kpa paper breaking resistance

$ 1413.00

use

The sheet burst Tester is used to test various tobacco sheets. The burst Tester is composed of a built-in measurement and control system and an LCD touch screen that can display the bursting rate curve and test results.

The burst Tester works according to the Mullen test principle: that is, through a piston, silicone oil is injected into the rubber film, the rubber film protrudes to deform the sample, the pressure continues to increase, and finally the sample ruptures, and the maximum pressure value applied is the burst resistance of the sample. Spend.

The Burst Tester is designed to meet the testing standards for paper, cardboard, corrugated cardboard, aluminum foil and textiles.

16032 is suitable for corrugated cardboard, cardboard, textiles and materials with high burst resistance.

Note: For materials with burst resistance below 600kPa, it is recommended to use 16031 model.

Test Principle

The burst Tester works according to the Mullen test principle: that is, through a piston, silicone oil is injected into the rubber film, the rubber film protrudes to deform the sample, the pressure continues to increase, and finally the sample ruptures, and the maximum pressure value applied is the burst resistance of the sample. Spend. The Burst Tester is designed to meet the testing standards for paper, cardboard, corrugated cardboard, aluminum foil and textiles.

Advantages

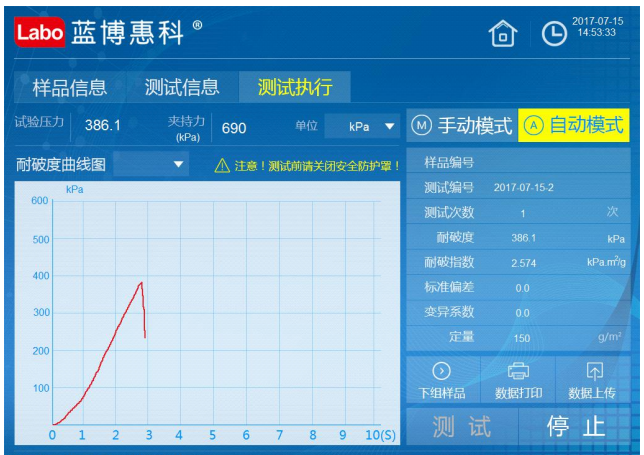

1. Effective detection and data processing system

The inspection system independently developed by LABO has a highly intelligent system architecture and realizes a fully automated inspection process. The inspection does not require manual intervention, reduces human measurement errors, and improves testing efficiency. The inspection data can be directly printed or uploaded to LABO-DMS via WIFI or RS3232 ( Experimental data management system)

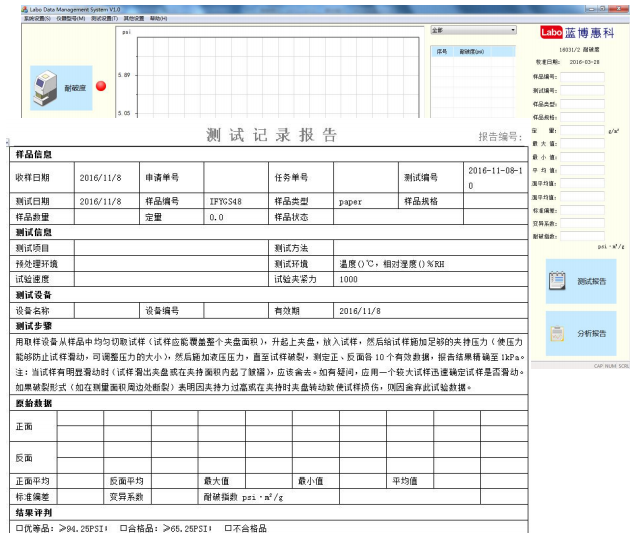

2. LABO-DMS system

Data processing: The test results are uploaded to the computer through WIFI or RS3232, and a single instrument or multiple instruments can be tested and transmitted online, realizing the sharing of one computer and a software system by multiple instruments, saving costs and improving efficiency.

Test report: The content of the report module can be edited by the user at will and generated in Word format.

Analysis report: According to the test results, the user can input the standard value to obtain the sampling failure rate. It can also make predictions and fluctuation analysis according to the test results and the actual temperature and humidity environment of the material, and form different analysis reports.

3. High precision pressure sensor

4. High reliability

Lanbo Burst Tester has passed a series of index verifications before leaving the factory to ensure that each instrument is reliable, stable, safe, and the measurement accuracy meets the specified requirements after leaving the factory.

5. Pneumatic system and safety protection device

6. Plexiglass safety shield

To prevent personal injury caused by putting hands in the chuck during testing and silicone oil splashing when the film is ruptured.

Features

8-inch large-screen LCD touch display measurement and control system

Chinese and English bilingual display

safety shield

Precise setting of sample clamping force (Japan SMC pneumatic system)

Imported high-precision pressure sensor (American precision)

Sample automatic induction test (automatic)

Test result calculation, printing and display of bursting curve

Sample information and test information can be entered by yourself

Test result output: WIFI or RS232

Standards

GB/T1539, GB/T454, QB/T1057, ISO 2758, ASTM D774, JIS 8112, TAPPI T 403

Technical indicators and parameters

| model | 16031 | 16032 |

| Test Range | 50-2,000KPa( 7–300psi,0.51–20.4kgf/cm²) | 250-6,000KPa(36–900psi, 2.55–61.2kgf/cm²) |

| Indication resolution | 0.1KPa | |

| Indication error | ±1% | |

| Indication Fluctuation | ≤1% | |

| Specimen holding force | (0~1400) KPa can be set arbitrarily | |

| Test system tightness | Pressure drop <10%Pmax within 1min | |

| Hydraulic (oil delivery) speed | (95±5)ml/min | (170±15)ml/min |

| Inner diameter of upper clamp ring hole | (30.5±0.05)mm | (31.5±0.05) mm |

| Inner diameter of lower clamp ring hole | (33.1±0.05) mm | (31.5±0.05) mm |

| Film thickness | (0.86±0.06) mm | |

| film resistance | When the protrusion is (9±0.2) mm, its pressure is (30±5) KPa | When the protrusion is (10±0.2) mm, the pressure is (170~220) KPa When the protrusion is (18±0.2) mm, the pressure is (250~350) KPa |

| test speed | 10 times/65 seconds | |

| Gas supply pressure: (0.6~0.8) MPa, gas source is prepared by the user; Gas consumption: 0.4m3/h; | ||

| Power supply: AC220V 50Hz; Dimensions: (D 380×W 240×H 530)mm; Net weight: 33kg | ||

Labo 16032 Sheet Burst TesterSpecifications

| LIST | VALUE |

|---|---|

| Measuring range | 20 ~ 6000kPa |

| resolution | 0.1kPa |

| Error of indication | ±1% |

| Indication of variability | ≤1% |

| Oil delivery speed | 170±15mL/min |

| Clamping Force | 0 ~ 1400Kpa |

| System tightness | 1Min pressure drop < 10% Pmax |

| Upper clamp ring aperture | F (31.5 ± 0.05) mm |

| Lower clamp ring aperture | F (31.5 ± 0.05) mm |

| Film resistance | Raise 10mm, 170kPa~ 220kPa; Raise 18mm, 250kPa~ 350kPa |

| Oil delivery speed | 10 times/65 seconds |

| Power | AC100-240V 50/60Hz 0.5A should be reliably grounded |

| Air source pressure | (0.6~ 0.8) MPa, gas source user-provided |

| gas consumption | 0.4m3/h |

| Dimensions | 380*240*530mm |

| Net Weight | 33kg |

Labo 16032 Sheet Burst Tester Packing list

complete-built unit X1, manual X1, certificate of conformity X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Optical inspection laboratory for coral reefs in Bermuda

- Application of Julabo Heating and Refrigeration Circulator in Petrochemical Industry

- Application of Julabo Heating and Refrigeration Circulator in Automotive Industry

- Application of Julabo Heating and Refrigeration Circulator in Semiconductor, Photovoltaic Photovoltaic Industry

- Application of Julabo Oscillating Bath in Pharmaceutical and Medical Industry

- Application of Julabo Heating and Refrigeration Circulator in Food Industry

- German Julabo heating thermostatic bath model comparison table

- ActiveJJF 1811-2020

- ActiveQB/T 1057-2020

- AbolishGB/T 454-2002

- ActiveJJG (轻工)61-2000

- AbolishJJG (轻工)61-2000

- ActiveJJF 1811-2020

- ActiveGB/T 10335.5-2008

- ActiveGB/T 465.1-2008

- ActiveISO 7784-3-2022

16032

16032