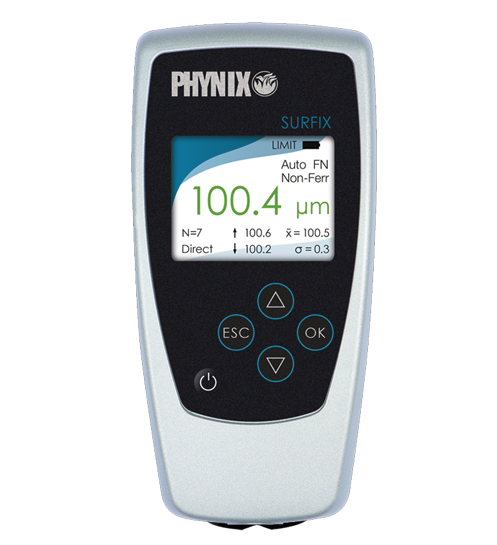

PHYNIX Surfix SX-F1.5 magnetic Film Thickness Gauge 1500μm

Magnetic Induction, measurement range 0~1500μm, error range +/- 1μm/2%, resolution 0.1μm, supports multiple operating languages, supports USB data transfer, can store up to 2,000 measurement values.

PHYNIX

PHYNIX-

DONGRU DR360 metal Thickness Gauge, professional measurement of the thickness of coated platings

$ 356.00 -

Defelsko NS conventional strip line probe measurement non-ferrous metal substrate coatings

$ 793.00 -

Defelsko PosiTector 6000 F1 Coating Thickness Gauge Iron metal substrate nonmagnetic coating

$ 871.00 -

Defelsko NAS split thin coating probe

$ 1049.00 -

LINSHANG LS239 Paint film instrument, car paint Thickness detection instrument Iron and aluminum substrate identification Bluetooth report

$ 176.00

Introduction

Coating thickness measurement: graphical display, PC connection, easy operation and proven PHYNIX probe

The outstanding feature of the PHYNIX coating Thickness Gauge is the brightly colored graphic display with improved text display and support for many different operating languages. The standard now includes English, German, French, Italian, Spanish, Turkish, Czech and Chinese. The internal memory has been significantly enlarged compared to the Surfix series and can now store up to 2,000 measured values. Simply connect to your computer via USB 2.0. PHYNIX.connect is a data transfer program for all modern Windows systems that facilitates the transfer of measured values ââto Excel.

Available in two models: Surfix® SX can be connected to all probes in the PHYNIX probe program. This ensures maximum flexibility, enabling the device to fulfill many different measurement tasks. Surfix® EX devices with fixed standard probes are suitable for applications with clearly defined measurement tasks. It is easy to use and more cost-effective than Surfix® SX with high-quality plug-in connections.

Application areas

Surfix®easy X is suitable for the following areas:

In the electroplating industry

in the painting industry

in the automotive industry

in the chemical industry

in aerospace engineering

in shipbuilding

In research laboratories and universities

in the workshop

consultants and appraisers

Product advantages

Innovative and user-friendly measurement technology

High-resolution color graphics display

USB interface

Automatic identification of base materials

Data memory stores up to 2,000 measured values

Online statistics

Intuitive menu guidance

Measurements on hot surfaces up to 150°C or 300°C (optional)

Manufacturer's test certificate

2 years warranty

Parameter comparison of PHYNIX coating Thickness Gauge series

|  |  |  |  | |

| Surfix Pro X | Surfix SX | Surfix EX | Pocket-Surfix X | Surfix easy X HR | |

| model | Split, replaceable probe | Split, replaceable probe | External fixed probe | Built-in probe | Built-in or external, fixed probe |

| Measuring range iron base | 30mm | 30mm | 1.5mm | 1.5mm | 3mm |

| Measuring range non-iron based | 3mm | 3mm | 1.5mm | 1.5mm | 3mm |

| Accuracy | ±(0.7μm+1% of reading) | ±(0.7μm+1% of reading) | ±(1μm+1% of reading) | ±(1μm+1% of reading) | 2μm or 2% reading |

| Hard metal probe | â | â | â | â | â |

| Factory calibration | â | â | â | â | â |

| Calibration method | Two-diaphragm calibration, single-diaphragm calibration, zero calibration, CTC | Single diaphragm calibration, zero calibration | Single diaphragm calibration, zero calibration | Single diaphragm calibration, zero calibration | zero calibration |

| Diaphragm calibration | â | â | â | â | - |

| Calibration storage | â | - | - | - | - |

| statistics | â | â | â | â | â |

| zero compensation | â | â | â | â | - |

| Boundary value | â | â | â | â | - |

| data storage | Up to 100,000 readings | Up to 2000 readings | Up to 2000 readings | Up to 80 readings | - |

| data transmission | Bluetooth/USB | USB | USB | USB | - |

| menu | â | â | â | â | - |

| Backlight display | â | â | â | â | â |

| continuous measurement | â | - | - | - | - |

| Solvent resistant probe | â | â | â | â | â |

| maximum surface temperature | 300℃ | 300℃ | 300℃ | 60℃ | 60℃ |

| Optional probe | â | â | - | - | - |

| Includes PC software | â | â | â | â | - |

PHYNIX Surfix SX-F1.5 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1500μm |

| margin of error | ±1μm/2% |

| Resolution | 0.1μm |

| Minimum measurement surface | 10x10mm |

| Minimum radius of curvature | Convex: 5mm; Concave "50mm |

| thinnest substrate | 0.5mm(F);0.05mm(N) |

| probe | built-in |

| Probe size | Φ14*83mm |

| Probe material | Carbide cutter head |

| Probe Weight | 70g |

| Calibrated mode | Factory zero calibrated |

| Unit display | μm |

| statistical function | Measurement times, MAX Maximum, MIN Minimum, Average, Standard deviation |

| Interface | USB 2.0 |

| Data storage | Up to 1000 readings |

| Power Supply | 2 AAA batteries |

| Standards | DIN、ISO、ASTM、BS |

| Display screen | High resolution color display |

| Operating temperature | 0 ℃ to + 50 ℃ |

| Protection level | IP52 |

| supporting software | Yes. |

| Machine Weight | 205G (with FN 1.5 probe and battery) |

| Machine size | 137*66*23mm |

| Probe contact temperature | - 15 ℃ to + 60 ℃ (standard); - 15 ℃ to + 150 ℃ or 300 ℃ (with optional high temperature feet) |

| Minimum headroom | 85mm |

| Accuracy of workpiece calibrating | +/- 3.0µm or 3% (whichever is greater) |

| Accuracy of foil calibrating | ±1μm sentire1% |

| Heat probe | Optional: - 15 ℃ to 150 ℃ |

| High temperature probe | Optional: - 15 ℃ to 300 ℃ (0 to 1,000 μm) |

PHYNIX Surfix SX-F1.5 Coating Thickness Gauge Packing list

Main unit, F1.5 probe, Rubber protective cover, 2 calibrated films, Zero standard sheet~ iron, 2 AA batteries, PHYNIX computer connection, user manual, manufacturer certificate, Encasement box

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 13912-2020

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveSY/T 0315-2013

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ActiveGB/T 1740-2007

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 6158-1984

- ISO 2361-1982

Surfix SX-F1.5

Surfix SX-F1.5

Surfix SX-N1.5

Surfix SX-N1.5

Surfix SX-FN1.5

Surfix SX-FN1.5