DAKOTA MVX A/B Ultrasonic Thickness Gauge

With PT-102-2700 standard high Impedance probe, Measurement range 1.0~150mm, upper and lower limit audiovisual alarm, pulse-echo mode, echo-echo mode (through coating), Data storage 12,000

DAKOTA

DAKOTA-

Ultrasonic Thickness Gauge DC-1000C Ultrasonic measurement Film thickness

$ 564.00 -

D7006 (Concave Curved Surface) Ultrasonic Thickness Gauge Probe

$ 245.00 -

LANDTEK TM8810 Ultrasonic Thickness Gauge Suitable for metal, ceramic, hard Rubber & plastics, Glass and other hard materials

$ 238.00 -

Metal Ultrasonic Film thickness meter DC-3020C Deguang Electronic Glass, steel pipe and other Film thickness measurement

$ 1575.00 -

KAIRDA NDT360 Ultrasonic Thickness Gauge 0.15~ 300mm

$ 2143.00

The MVX v2.0 is our most basic A-scan thickness range for professional thickness applications. It goes beyond our basic digital gauge series and offers oscilloscope-based versatility. Display options include: RF, Rectifier, B-Scan, and Large Numbers. The alphanumeric data logging format with 4Gb of internal SD memory can provide more storage space than ever before. Our custom settings feature allows for 64 definable settings per file, and as many files can be set as needed. Transducer meters for improved linearity, paint mode at the touch of a button, multiple calibration and material selection options, and auto-waveform finding capabilities – just to name a few! These are nicely packed in a very small portable aluminum profile for extra durability and portability!

Features

- Tunable square wave pulses for high resolution and penetrationDepth and other requirements

- MVX has a variety of field of view options, including RF displaysDisplay, detection, time-based B-scan, and large-format digital display

- The A-scan detection mode is in the pulse-echo modeDetect defects/holes and penetrate in echo-echo modeA mode in which measurements are made through the coating

- The MVX's time-base B-scan shows the breakage of the material being measuredFaces, which are often used to show the contour of the underside of the material being measured

- Gain control with built-in AGC hardware for multi-mode operationPrepared for the measurement of penetrating coatings

- Multiple calibration options are versatile for MVXexample

- MVX can store 64 user-defined settingsThere are settings that can be selected, edited, and saved to anythinglocation

- MVX has alphabet data memory to satisfy usersReporting requirements

- Built-in probe type improves probe linearity

- High-speed scanning capability for 32 measurements per second. Will probeWhen the head is removed from the material to be measured, a scan measurement is displayedminimum value

- The MVX has an audio-visual alarm function for the upper and lower limits

- Use the search function to locate detection points and automatically adjust the displayindicates that the transmitted signal enters the field of view

- Data can be transferred using Windows PC software

Measuring range

Pulse-echo mode: 0.63~254mm (steel)

Echo-echo mode: 2.54~102mm (steel, measured through coating)

Resolution: 0.01mm

Sound velocity range: 1250~9999m/s

Unit: Metric or Imperial

display screen

VGA gray display, 240x160Pixels.

Viewport 62x45.7mm, EL backlight

A-Scan: Detection +/- (Defect Field of View), RF (Full Wave Field of View)

B-Scan: Passes through the cross-sectional field of view at a display speed of 15 seconds per screen

Large digital display

Standard thickness display, 10mm high

Thickness bar scanning

6 readings per second, visible in B-scan and large digital display

Measurement mode

Pulse-echo mode, echo-echo mode (through coating)

Pulse: Adjustable square wave pulse

Reception:Choose between manual or AGC gain control in the 40dB range depending on the mode

Built-in memory

Storage: 12,000 storage pages (alphanumeric storage)

Contents: 1 reading and one waveform per page

Output: Bidirectional RS232 interface, Windows PC interface software

Settings: 64 user-defined settings, factory settings can also be edited

sluice gate

Pulse-echo mode single gate, echo-echo mode single gate, gate adjustable

Alarm mode: upper and lower limit audio-visual alarm

Quick scan mode

32 readings per second, with a minimum value displayed when the probe leaves

Power supply and others

Three gauge 5-gauge alkaline batteries for 150 hours of use

Battery level display

Automatic power off after 5 minutes of no operation

Keyboard: 12 touch keys

Shell: Extruded aluminum casing, bottom cover is sealed with nickel-plated aluminum plate and gasket

Operating temperature: -10~60°C

Dimensions and weight: 63.5 x 165 x 31.5mm, including battery 385g

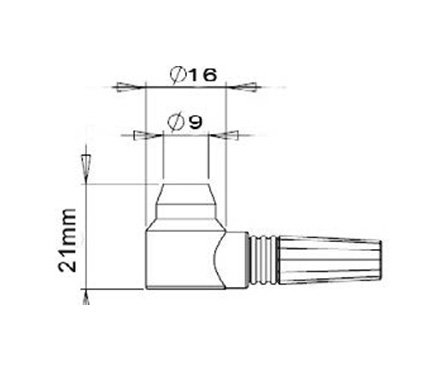

Probe models are available

| Model | frequency | Element diameter | Contact diameter | Measuring range | illustrate |

| PT-102-2700 | 5.0MHz | Ø6.3mm | Ø9.53mm | 1.0~150mm | Standard high-impedance probe (standard probe) |

| PT-101-2000 | 5.0MHz | Ø4.7mm | Ø6.35mm | 1.5~50mm | Small diameter probes |

| PT-101-2700 | 5.0MHz | Ø4.7mm | Ø6.35mm | 1.5~50mm | Small diameter high impedance probe |

| PT-104-0000 | 1.0MHz | Ø12.7mm | Ø15.88mm | 3.8~50.8mm(Cast Iron) | Cast iron probe |

| PT-102-1000 | 2.25MHz | Ø6.3mm | Ø9.53mm | 1.0~150mm | Low-frequency probes |

| PT-104-2000 | 5.0MHz | Ø12.7mm | Ø9.53mm | 1.27~500mm | Extra-thick probe |

| PT-104-2700 | 5.0MHz | Ø12.7mm | Ø15.88mm | 1.27~500mm | Ultra-thick high-impedance probe |

| PT-102-3300 | 7.5MHz | Ø6.3mm | Ø15.88mm | 0.63~150mm | Ultra-thin probe |

| PT-102-3700 | 7.5MHz | Ø6.3mm | Ø9.53mm | 0.63~150mm | Ultra-thin high-impedance probe |

| PT-042-2000 | 5.0MHz | Ø6.3mm | Ø9.53mm | 1.0~150mm | Standard high-temperature probes < 340°C |

| PT-042-2700 | 5.0MHz | Ø6.3mm | Ø15.88mm | 1.0~150mm | Standard high temperature high impedance probes < 340°C |

| PT-044-2000 | 5.0MHz | Ø12.7mm | Ø15.88mm | 1.27~500mm | Ultra-thick high-temperature probe < 340°C |

| PT-044-2700 | 5.0MHz | Ø12.7mm | Ø9.53mm | 1.27~500mm | Ultra-thick high-temperature, high-impedance probe < 340°C |

| PT-212-2001 | 5.0MHz | Ø6.3mm | Ø15.88mm | 1.0~150mm | High temperature probe < 482°C |

| PT-214-2001 | 5.0MHz | Ø12.7mm | Ø15.88mm | 1.27~500mm | Ultra-thick high-temperature probe < 482°C |

Note: If using echo-echo mode for penetrating coating measurements, it is recommended to select a high-impedance probe

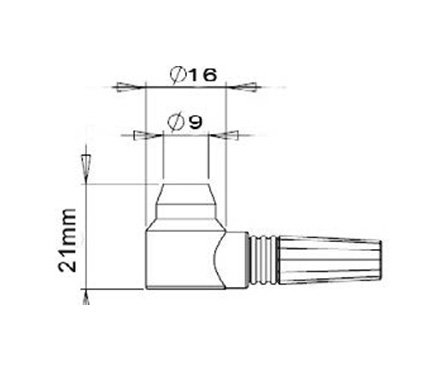

DAKOTA MVX Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 1.0~150mm |

| Probe style | PT-102-2700 Standard High Impedance Probe |

| Probe Frequency | 5.0MHz |

| Speed of sound | 1250~9999m/s |

| unit system | Metric or imperial system |

| Display resolution | 0.01mm |

| Probe diameter | Φ6.3mm |

| Probe diameter | Φ9.53mm |

| Alarm function | Upper and lower limit audio-visual alarm |

| Measurement mode | Pulse-echo mode, echo-echo mode (through coating) |

| Display | VGA gray display, 240x160 pixels. |

| Data storage | 12,000 storage pages (alphanumeric storage) |

| Interface | To RS232 interface, Windows PC interface software |

| Shell material | Extruded aluminum case, bottom cover is sealed with nickel-plated Aluminum Panel and sealing pad |

| Host size | 63.5*165*31.5mm |

| Weight | 385G (including battery) |

| Environmental temperature | -10~60℃ |

DAKOTA MVX Ultrasonic Thickness Gauge Packing list

host X1, PT-102-2700 probe, coupling agent X1, No. 5 battery X2, factory certificate x1, Chinese and English instructions x1, instrument case x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle of Portable Ultrasonic Thickness Gauge

- Measurement principle and influencing factors of high temperature ultrasonic Thickness Gauge

- Types and Usage Methods of Coupling Agent for Thickness Gauges

- The Principle, Application and Precautions of Copper Plate Ultrasonic Thickness Gauge

- Principle, Application and Selection of Ceramic Ultrasonic Thickness Gauge

- Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- Principle, Application and Type Selection of Ultrasonic Thickness Gauge

MVX

MVX