JINGKELIAN QCJ-120A film impact test device 120cm/1000g GB/T 5237.4

Impact height 120cm, Impact height 120cm, sub-scale 1cm, drop weight mass 1000g, Striker Diameter φ 16mm, Impact depth 2.5mm, die base aperture φ 15mm, curvature radius R2.5-3mm, meet the standard GB/T 5237.4-2000.

JingKeLian

JingKeLian-

Impact Tester TQC SP1890 meets ISO 6272-1 standard

$ 4174.00 -

Impact Tester TQC SP1895 coating imapct Tester ASTM G14

$ 5252.00 -

YONGLIDA TCJ Elastic Impact Tester 100cm ASTM D2794, ISO6272

$ 609.00 -

YONGLIDA QCJ-120 Film Impact Device 120cm/1000g GB/T1732

$ 340.00 -

CHINA BLD-CJ21 (2M) Impact Tester Plastic, Ceramic, Acrylic fiberglass

$ 435.00

Introduction

The QCJ-120 (120A, 120B) series paint film impact Tester is used for the paint film impact resistance test represented by the maximum height of 120 cm when a weight with a fixed mass falls on the test plate without causing damage to the paint film. After the impact head of this instrument impacts the test plate, there is no secondary rebound phenomenon.

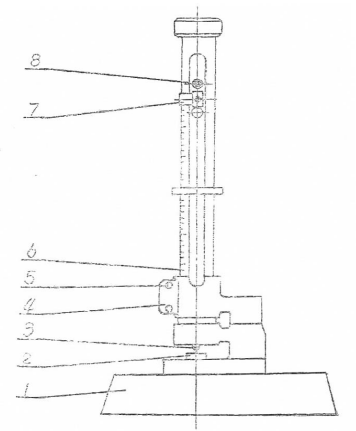

The main structure

1. Base; 2. Pillow block; 3. Punch rod; 4. Support arm; 5. Screw; 6. Slider; 7. Positioning mark; 8. Controller component

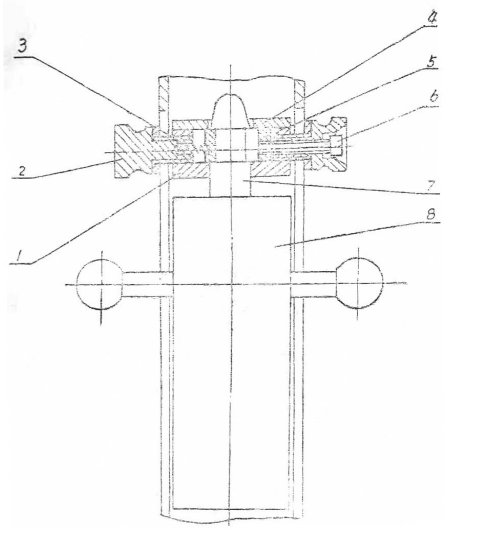

1. The lower bottom of the controller; 2. The electrical part of the controller; 3. The spring of the controller; 4. The upper cover of the controller; 5. The slider of the controller; 6. The control screw; 7. The hook; hammer assembly

Principle

The weight with the hook is fixed at the required height by the controller screw, and its height is that the height mark line shown on the slider scale coincides with the positioning mark line. Press the control screw to compress the spring of the controller. At this time, the round hole of the control slider is aligned with the round hole of the upper cover of the controller and the round hole of the lower bottom of the controller, so that the hook falls off, the weight falls, hits the punch, and the punch acts downward. On the test plate previously placed on the pillow blocks. Afterwards, lift the weight body and take out the test panel to observe the test condition of the paint film on the test panel.

QCJ series impact Tester parameter comparison

| Instrument model | QCJ-120 type | QCJ-120A type | QCJ-120B type |

| Instrument scale length | 120±0.2cm | 120±0.2cm | 120±0.2cm |

| graduation | 1cm | 1cm | 1cm |

| Hammer mass | (1000±1) g | (1000±1)g | (2000±2)g |

| Impact head specification | S diameter 8mm | S diameter 16mm | S diameter 16mm |

| Pillow Block Hole Diameter | 15mm | 15mm | 16.3mm |

| radius of curvature | R2.5-3mm | R2.5-3mm | R2.5-3mm |

| Impact depth of impact head | (2±0.1) mm | (2.5±0.1)mm | (2.5±0.1)mm |

| hospitality standard | GB/T1732—93 Test method for impact resistance of paint film | GB/T5237.4-2000 Aluminum Alloy Architectural Profiles Part 4 Powder Coated Profiles | ASTM D2794-92 Test method for resistance to rapid deformation (impact) of organic coatings |

JingKeLian QCJ-120A Film impact testSpecifications

| LIST | VALUE |

|---|---|

| Impact height | 120cm |

| Impact height | 120cm |

| Graduation | 1cm |

| Drop Weight Mass | 1000g |

| Striker Diameter | Φ16mm |

| Impact depth | 2.5mm |

| die base aperture | Φ15mm |

| radius of curvature | R2.5-3mm |

| Meet the standard | GB/T 5237.4-2000 |

| material | iron |

| principle | Impact film by letting the Weight drop freely from a certain height to determine the impact strength of the film |

| function | Impact performance of the coating surface is tested, and the impact resistance and adhesion of the coating are evaluated by simulating the force of falling, impact and friction on the coating surface. |

JingKeLian QCJ-120A Film impact test Packing list

Instrument host X1, manual X1, certificate X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveJJF 002-2015

- ActiveJB/T 7455-2007

- ActiveJG/T 512-2017

- ActiveSH/T 3022-2019

- ActiveWJ 2669-2005

- ActiveASTM

- ActiveJT/T 821.1-2011

- ActiveDL/T 2308-2021

- ActiveJG/T 224-2007

- ActiveHG/T 5060-2016

- ActiveHG/T 4338-2012

- Active 0025-2018

- ActiveHG/T 5176-2017

- ActiveHG/T 5059-2016

- ActiveDB 44/T 1106-2012

- ActiveDB 44/T 1024-2012

- ActiveHG/T 5368-2018

- ActiveHG/T 4568-2013

- ActiveHG/T 4770-2014

- Active 2421-2022

QCJ-120A

QCJ-120A

QCJ-120B

QCJ-120B

QCJ-120

QCJ-120