TIME2110 (formerly TT100) Ultrasonic Thickness Gauge Suitable for Metals, Plastics, Ceramics, Glass, etc

TIME Ultrasonic Thickness Gauge TIME2110, prototype number TT100, is a portable Ultrasonic Thickness Gauge with wire probe, TIME2110 can Measuring temperature up to 300 ℃, suitable for petroleum, chemical, metallurgy, shipbuilding, aviation, aerospace and other fields.

TIME

TIME-

DUBAN DB22-TM240A Ultrasonic Thickness Gauge 200mm/0.1mm

$ 376.00 -

Mattel MT150 Ultrasonic Thickness Gauge Thickness Range 0.75~ 300mm Resolution 0.1mm

$ 309.00 -

D7006 (Concave Curved Surface) Ultrasonic Thickness Gauge Probe

$ 245.00 -

Linshang LS213 Professional Ultrasonic Thickness Gauge Thickness Measurement 0.8~ 350mm

$ 176.00 -

LEEB LG5 High Temperature Probe up to 300 ℃ for Ultrasonic Thickness Gauges

$ 195.00

Introduction

Beijing TimesTIME2110 (formerly TT100) Ultrasonic Thickness GaugeIt is a red shell, external probe type ultrasonic thickness measuring instrument,TIME2110The ultrasonic Thickness Gauge can not only measure the thickness of the workpiece material but also use the thickness to measure the sound velocity, can achieve different measurement ranges for different object environments, has an underVoltage indication function, and can be applied to measure high-temperature objects up to 300°C, and can store 10 measured values.

The principle of product thickness measurement

TIME2110 ultrasonic Thickness Gauge is based on the principle of ultrasonic pulse reflection to measure the thickness, when the ultrasonic pulse emitted by the probe passes through the measured object to the material interface, the pulse is reflected back to the probe, and the thickness of the measured material is determined by accurately measuring the time of ultrasonic wave propagation in the material. Times ultrasonic Thickness Gauge series is a collection of contemporary science and technology electronic technology and measurement technology in one, professional non-destructive testing instruments, the use of microcomputer to analyze, process, display the data time, the use of highly optimized measurement circuit, with high measurement accuracy, wide range, easy operation, stable and reliable work and other characteristics. This principle can be used to measure any material that allows ultrasonic waves to propagate within it at a constant speed. The instrument uses the ultrasonic principle to measure the thickness of any ultrasonic conductor material, such as metals, plastics, ceramics, and glass. It can accurately measure all kinds of plates and processed parts, and is widely used in petroleum, chemical industry, metallurgy, shipbuilding, aviation, aerospace and other fields.

Live shot

Advantages

1. It has the function of automatic nonlinear compensation, and can use computer software to correct the nonlinear error of the probe in order to improve the accuracy of measurement.

2. Data storage function, which can store 10 measured values.

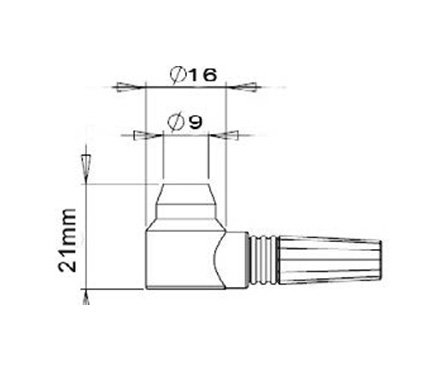

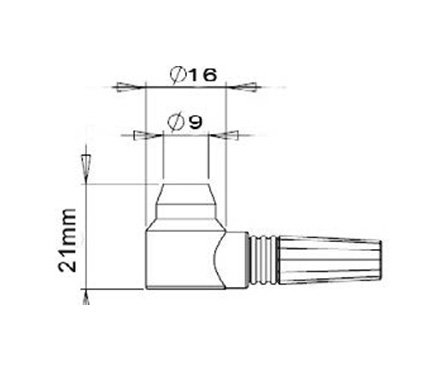

3、TIME2110 ultrasonic Thickness GaugeYes2.5Mz, 5Mz, 7Mz three probes are optional.

4. Large-screen LCD display, with automatic shutdown function.

5、TIME2110 ultrasonic Thickness GaugeThe velocity of sound can be measured using a test block of known thickness.

6. It is suitable for measuring metal, plastic, ceramic, glass and any other good conductor of ultrasonic.

7. There are only two buttons, which is simple to operate and suitable for measuring steel materials.

8. With high temperature measurement function, the surface temperature of the object on the side can reach up to 300°C

Features

●It has two display functions: metric system and imperial system

●Automatic calibration of the zero point, which can correct the system error

●Automatic linearity compensation, using computer software to correct the nonlinear error of the probe in the whole range to improve the accuracy

●The upper and lower adjustment keys can be used to quickly adjust the sound velocity and thickness, and the thickness storage unit can be quickly queried

●Coupling state prompt: Provide a coupling flag, and you can know whether the coupling is normal by observing its stable state

●Ten thickness values can be stored, and the data will not be lost after shutdown, which brings convenience to high-altitude and field work

●Sound velocity measurement function: directly measure the sound velocity according to the thickness of the sample, avoiding the trouble of checking the table or conversion

●TIME2110 ultrasonic Thickness GaugeIt can store the sound velocity of five different materials

●Low Voltage prompt

● Auto shutdown: Scheduled auto shutdown will help you break the point

●Full key membrane closed operation - anti-oil stain and improve service life

TIME TIME2110(原TT100) Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 1.2~225mm |

| Probe Frequency | 2.5/5/7MHz |

| Probe style | Split probe |

| Probe contact temperature | ≤300℃ |

| Measurement error | ±(1%H+0.1)mm |

| Display resolution | 0.1mm |

| unit system | mm |

| Calibration method | Zero calibrated |

| Repeatability | 0.1mm |

| Storage Capacity | 10. |

| Speed of sound | 1000~9999m/s |

| Display | Four-digit LCD display |

| Operating language | Chinese |

| Application Software | without |

| Environmental temperature | 0~40℃ |

| Power Supply | 2 * 7 AAA battery |

| power consumption | Operating current < 20mA (3V) |

| Weight | About 140g |

| Application | Metals, Plastics, Ceramics, Glass and Miscellaneous Good conductors of any ultrasound |

| Surface measurement error of indication (steel) | Should be 20mmx3.0mm, (5PShould 10 probe, 5PShould 10/900 probe), Should be 15mm x2.0mm (7PShould 6 probe), error of indication does not exceed +/- 0.1mm |

| Speed of sound measurement error | When H ≤ 20mm, the measurement error does not exceed +/- 1mm/HX100%; when H > 20mm, the measurement error does not exceed +/- 0.1 |

| Voltage Variable Stability (Steel) | 0.1mm |

| Low Voltage indication | After the thickness gauge is turned on, when the battery Voltage is 2.2V +/- 0.2V, the screen displays "BATT" |

| Measurement range (steel) | 0.75~60.0mm |

TIME TIME2110(原TT100) Ultrasonic Thickness Gauge Packing list

host x1, suitcase x1, host protective cover x1, 5P < unk > 10/90 probe x1, AA type alkaline battery x2, coupling agent x1, random file x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Ultrasonic Thickness Gauge in Oil Drilling Tools Production

- Application of Ultrasonic Thickness Gauge in Spinning Tube Abrasion Monitoring

- Influencing factors of ultrasonic thickness indication distortion

- Application of Ultrasonic Thickness Measurement Technology- "Selection of Thickness Gauges"

- How to measure the thickness of galvanized layer _ galvanized layer thickness inspection method

- Ultrasonic Instrument FAQ

- How to choose a Thickness Gauge?

- Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- Diagnostic Application of Ultrasonic Thickness Gauge in Gas Pipeline Inspection

- Ultrasonic Thickness Gauge Speed of sound coarse adjustment range error measurement results Uncertainty evaluation