MODERNER WDW-300 Electronic Multifunctional Testing Machine 300KN

MODERNER WDW-300 electronic multifunctional testing machine is used to test the test force value, fracture force value, yield strength, up and down yield strength, tensile strength, compressive strength, etc. The test force is 300KN, and the test force accuracy of WDW-300 is better than the indication +/- 1%.

Moderner

Moderner-

Taichang TC-DLJ01 Microcomputer Tensile Tester 1000mm Stroke CHINA Sensors

$ 1145.00 -

HBO ZT-200 Small Electric Spring Testing Machine, Range 200N

$ 2050.00 -

BaidaJUSHI LY-7012A Small Tensile Testing Machine 200KG

$ 1019.00 -

Haibao LYD-5T gantry microcomputer-controlled universal testing machine, measuring range 50KN/5000KG

$ 4580.00 -

CHINA NBC-1021 Touch screen single column Tensile Strength Tester 20KG

$ 1169.00

Introduction

WDW series microcomputer controlled electronic multi-functional testing machine is suitable for tensile testing of rubber, plastics, textiles, waterproof materials, wires and cables, mesh ropes, carbide, metal wires, metal rods, metal plates and other materials, with additional accessories Compression and bending tests can be performed.

Field of use

The testing machine uses a stepper or AC servo motor as the power source; it adopts professional chip integration technology and a professionally designed PCI data acquisition amplification and control system. The test force, deformation amplification, and A/D conversion processes realize full digital adjustment. This machine can test and analyze the mechanical properties of various metals, non-metals and composite materials. It is widely used in aerospace, petrochemical industry, machinery manufacturing, wires, cables, textiles, fibers, plastics, rubber, ceramics, food, medicine Packaging, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, wood, paper, metal materials and manufacturing industries, the maximum test force value, breaking force value, yield value can be automatically calculated according to GB, JIS, ASTM, DIN, ISO and other standards Strength, upper and lower yield strength, tensile strength, compressive strength, elongation at break, tensile elastic modulus, bending elastic modulus and other test data.

According to the standard

The relevant auxiliary equipment is configured to meet the national standards GB/T228-2002, GB/T228-2010 "Metal Materials Tensile Test Method at Room Temperature", GB/T7314-1987 "Metal Compression Test Method", GB/T232-2010 "Metal Bending Test Method" ã, GB/T9341-2000 "Plastic bending properties test method", GB/T2568-1995 "Resin cast body tensile test method", GB/T1040-92 "Plastic tensile property test method", GB/T1041-1993 " "Plastic Compression Performance Test Method", GB/T 9341-2000 "Plastic Flexural Performance Test Method", GB/T 25042-2010 "Glass Fiber Architectural Membrane", data in compliance with GB, ISO, ASTM, DIN and other standards deal with. It can be manufactured according to the user's requirements and provided standards.

B/T16491 "Electronic Multi-Function Testing Machine";

GB/T2611 "General technical requirements for testing machines";

GB/T6825.1 "Inspection of Static Uniaxial Testing Machines Part 1: Inspection and Calibration of Force Measuring Systems of Tensile and/or Compression Testers";

JB/T6146 "Technical Conditions of Extensometer";

JJG475 "Calibration Regulations for Electronic Multifunctional Testing Machines"

Key description

1 Host: This machine adopts a gantry floor-standing dual-space structure. It can be pulled up and pressed down. The lifting and lowering of the beam can be steplessly adjusted. The test space can be changed after replacing the column, screw, and outer cover. The transmission system consists of a low-noise arc synchronous toothed belt reduction system and a ball screw pair. It operates smoothly, has high efficiency, low noise and no pollution.

2 accessories:

Standard configuration: One pair of lever-type tension attachments and one pair of compression attachments. The stretching attachment adopts manual clamping method, which is convenient, reliable and non-slip. During the clamping process, the jaws do not move and the clamp body moves up and down. The sample is not subject to additional force, ensuring the accuracy of the test results.

Features

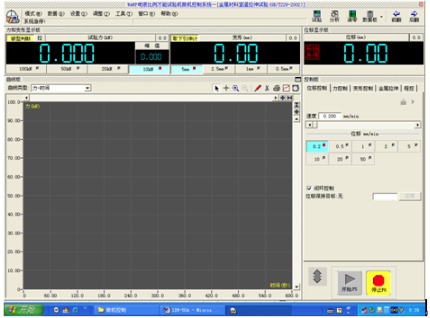

a) This machine uses a built-in controller to ensure that the testing machine can achieve constant velocity displacement control.

b) It adopts stepper or AC servo motor, with stable and reliable performance, and has overcurrent, overVoltage, overspeed, overload and other protection devices. The speed ratio can reach 1:10000.

c) The electrical control circuit refers to international standards and complies with the national testing machine electrical standards. It has strong anti-interference ability, ensuring the stability of the controller and the accuracy of experimental data.

d) Automatic gear shifting: Automatically switches to the appropriate range according to the load size to ensure the accuracy of measurement data; realizes automatic gear shifting, zeroing, calibration and true physical zeroing, gain adjustment and test force measurement. Save, without any analog adjustment link, the control circuit is highly integrated

e) Condition storage: test control data and sample conditions can be made into modules, which facilitates batch testing;

f) Automatic speed change: The speed of the moving beam during the test can be changed automatically according to a preset program or manually;

g) Automatic calibration: The system can automatically calibrate the accuracy of the indication value;

h) Automatic saving: After the test is completed, the test data and curves are automatically saved;

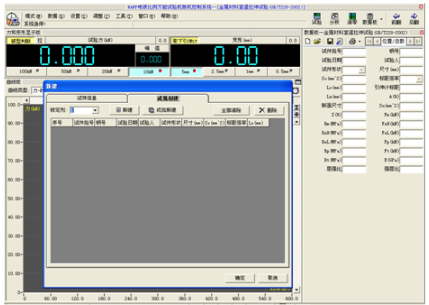

i) Process realization: The test process, measurement, display and analysis are all completed by microcomputer;

j) Batch test: For samples with the same parameters, they can be completed sequentially after one setting;

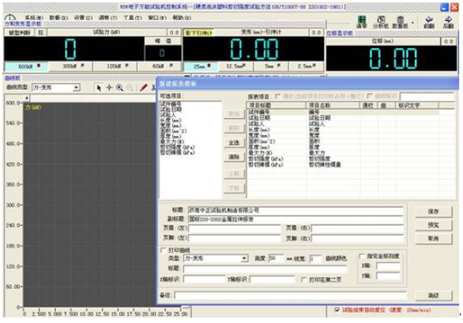

k) Test software: Chinese WINDOWS interface, menu prompts, mouse operation;

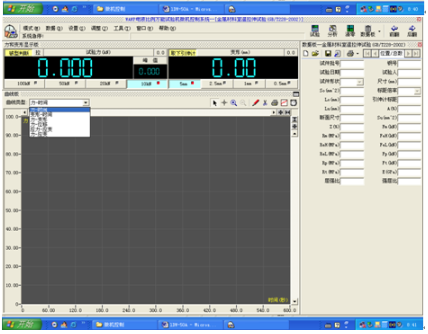

l) Display mode: data and curves are dynamically displayed along with the test process;

m) Curve traversal: After the test is completed, the curve can be reanalyzed, and the test data corresponding to any point on the curve can be found with the mouse;

n) Curve selection: stress-strain, force-displacement, force-time, displacement-time and other curves can be selected for display and printing as needed;

o)

p)

q) Test report: The report can be prepared and printed in the format required by the user; it has a network interface for data transmission, storage, printing records and network transmission and printing, and can be connected to the enterprise's internal LAN or Internet network.

r) Limit protection: It has two levels of program-controlled and mechanical limit protection;

s) Automatic stop: After the sample breaks, the moving beam stops automatically;

t) Overload protection: When the load exceeds 3-5% of the maximum value of each gear, it will automatically stop;

There are two modes, automatic and manual, to obtain test results and automatically generate reports, making the data analysis process simple.

Moderner WDW-300 Microcomputer-controlled electronic universal testing machineSpecifications

| LIST | VALUE |

|---|---|

| structural form | portal |

| Maximum test force | 300KN |

| Operation mode | Microcomputer control |

| Force Measurement Range | 2~100% |

| Test force Accuracy | +/- 1% better than indication |

| distortion display error | +/- 1% (or ± 0,5%) |

| Test force minimum resolution | 0.01N |

| Beam displacement Accuracy | ±1%(±0.5%) |

| Deformation Accuracy | Better than +/- 1% (± 0.5%) |

| Test speed range | 0.01~500/200mm/min |

| effective travel | > 700m (can be customized according to customer needs) |

| test width | 400mm |

| Test space adjustment mechanism | Servo motor, synchronous belt drive |

| Appearance | Comply with the national GB/T2611 standard |

| protection function | Overload protection, limit protection |

| Power | 220V |

| Weight | 500kg |

| Operating Environment | Room Temperature -35 ℃, Humidity 20%~ 80% |

| Fixture configuration | According to customer requirements, configure suitable fixtures. Special fixtures can be customized according to customers |

Moderner WDW-300 Microcomputer-controlled electronic universal testing machine Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

WDW-300

WDW-300