SETCAS KW-4E-I programmable homogenizer, remotely controlled

Maximum support 8 inches, touch screen with program control, PTFE cavity, integrated heating and temperature control function, remote control function, maximum speed 12000rpm.

Setcas

Setcas-

SETCAS setcas KW-4BC-I homogenizer adjustable adsorption

$ 2913.00 -

Chengyue CY-SPC4-PP Spinning Coater aluminum alloy structure 10000 rpm, program-controlled homogenization

$ 1572.00 -

HuiNuo 12T25 glue baking machine, touch multi-stage thimble Spinning Coater

$ 1414.00 -

SETCAS setcas KW-4E-II program-controlled Spin Coater, automatic glue drop + remote control

Login -

SETCAS KW-4S Heated homogenizer for glove box

Login

Advantages

PTFE polymer chamber material, acid and alkali resistance, corrosion resistance, with a curved chamber bottom to facilitate glue export;

It has the function of exhaust gas pumping and exhausting in the chamber;

Gas heating and drying, temperature range: 0-200°C, heating and cooling speed 100°C/S; forward and reverse spin coating directions can be switched freely;

Real-time display of speed rise curve;

It has the functions of motor glue feeding alarm and protection;

It has alarm and interlock functions for insufficient substrate adsorption force.

Product Structure

Function introduction of KW-4E-I front left view angle

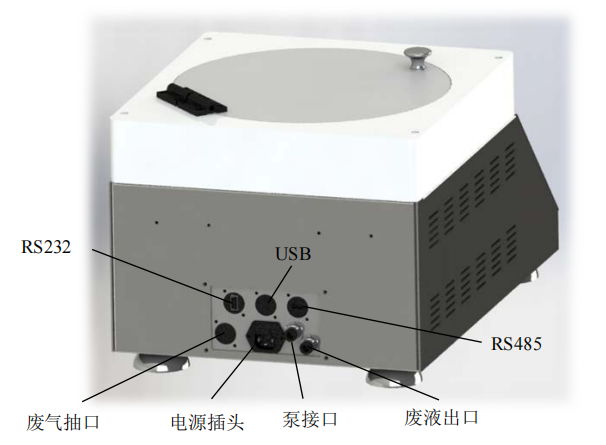

Function introduction of KW-4E-I rear right view angle

KW series homogenizer model comparison

Setcas KW-4E-I Glue levelerSpecifications

| LIST | VALUE |

|---|---|

| Suitable substrate | 5~200mm |

| Speed range | 1~12000rpm |

| Speed Accuracy | 1rpm |

| Speed stability | ±0.1% |

| Acceleration range | 1~10000rpm/s |

| Swirl/spin direction | Forward and reverse can be switched |

| glue uniformity | ±1% |

| Heating range | RT+~200°C |

| Heating speed (chamber air temperature) | To 100 ℃ (1S), to 200 ℃ (2S) |

| Chill down | To room temperature (2S) |

| Human Machine Interface | 8 inch touch screen |

| Communication interface | USB (std.) |

| stylus | BAMBOO Resistance Pen (std.) |

| Vacuumpump | SC-550V no oil pump |

| Set data | Unlimited sets of data, 15 revolutions per set (std.) |

| Program every time | 0~10000s |

| Store data | Unlimited set of data |

| Data Protection | Default with power-down protection function |

| AC Power port of glue leveler | AC100-250V |

| Vacuumpump Power interface | AC220V (std.) |

| Gluer power | 650W |

| Vacuumpump power | 350W |

| Vacuumpump pumping rate | ≥60L/min |

| Volume of homogenizer | 340*500*250mm |

| Gluer Weight | 18KG |

| Pump Weight | 9KG |

| Environment temperature | 0~40℃ |

| Relative Humidity | <85% |

Setcas KW-4E-I Glue leveler Packing list

complete-built unit X1, manual X1, certificate of conformity X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What are the special requirements for spin-coated nanoparticles?

- Spin Coater selection and classification: a one-stop guide

- What are the common problems of spin coating experiment?

- Spin coatings spin coaters: principles, applications, functions and maintenance

- Common Problems and Maintenance Measures of Spin Coater of Gluer

- Three small suggestions for improving the effect of spin coating

- Detailed operation steps schematic diagram of the glue leveler

- Four key stages of spin coating

- Common defects in spin coating of homogenizer

- What is spin coating and how does it work?

KW-4E-I

KW-4E-I

KW-4E-II

KW-4E-II

KW-4E

KW-4E