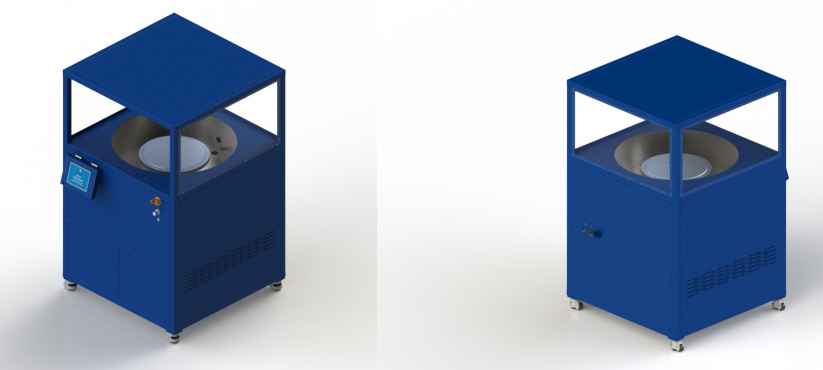

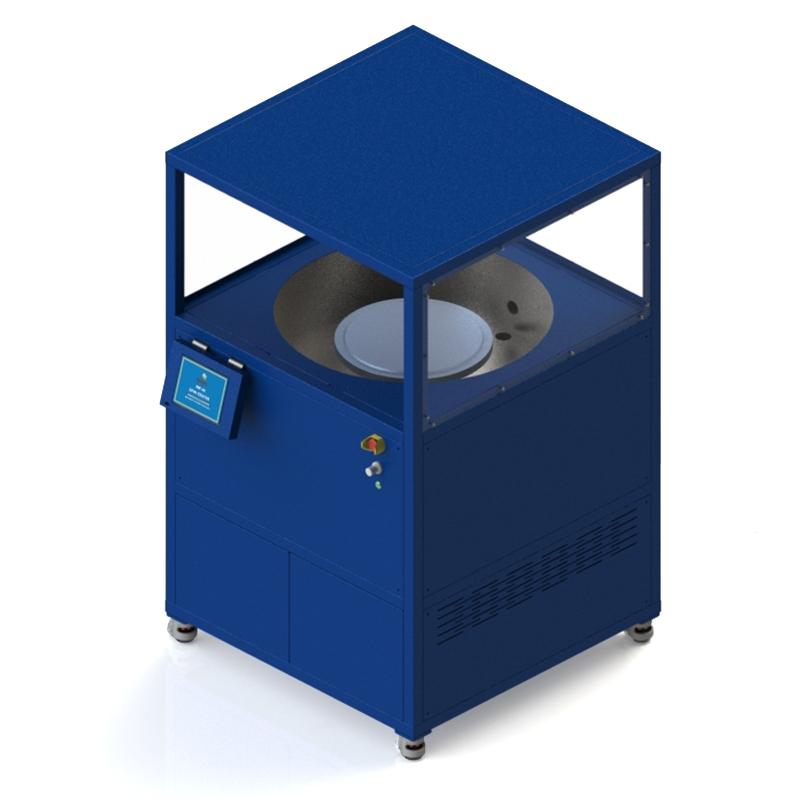

SETCAS KW-4K experimental homogenizer with support for 18-inch substrates

Maximum support 18 inches, touch screen with program control, with foot switch, with communication interface, formula with power-down protection function, maximum speed 3000rpm, distribution center alignment tool

Setcas

Setcas-

CHINA 12AC touch screen homogenizer, fixed Acceleration Spin Coater

$ 1145.00 -

SETCAS KW-4L Spin Coater

Login -

Chengyue CY-SPC4-PMMA Spinning Coater Spin Coater 10000 rpm programmable homogenizer

$ 1429.00 -

HuiNuo HN-SPC8-SS heated Spinning Coater stainless steel cavity

$ 6071.00 -

CHINA 16Ez small uniform glue machine, touch screen Spin Coater Power 150W

$ 1429.00

Features

1. With glue protection and alarm;

2. Insufficient adsorption alarm and interlock;

3. The motor can be reversed;

4. With communication interface;

5. Mouse and keyboard can be connected;

6. Formula with power-down protection function;

7. With foot switch.

Setcas KW-4K Glue levelerSpecifications

| LIST | VALUE |

|---|---|

| Suitable substrate | 200~450mm/200~600mm (custom) |

| Speed range | 1~3000rpm |

| Speed Accuracy | 1rpm |

| Speed stability | ±0.1% |

| Acceleration range | 1~1000rpm/s |

| glue uniformity | ±1% |

| Human Machine Interface | 8 inch touch screen |

| Communication interface | USB (std.)/RS485 (std.)/Bluetooth (optional) |

| stylus | BAMBOO Resistance Pen (std.) |

| Vacuumpump | AP-550V no oil pump/FY oil pump |

| formula | Unlimited sets of data, each set of 15 speed (std.) or no speed (optional) |

| Every time | 0~10000s |

| Store data | Unlimited set of data |

| Data Protection | Default with power-down protection function |

| Swirl/spin direction | Can be reversed |

| AC Power port of glue leveler | AC100-250V |

| Vacuumpump Power interface | AC220V (std.) AC110V (optional) |

| Gluer power | 5KW |

| Vacuumpump power | 350W |

| Vacuumpump pumping rate | ≥60L/min |

| Volume of homogenizer | 1000*1000*1650mm |

| Gluer Weight | 200KG |

| Pump Weight | 9KG |

| Environment temperature | 0~40℃ |

| Relative Humidity | <85% |

Setcas KW-4K Glue leveler Packing list

complete-built unit X1, manual X1, certificate of conformity X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Three small suggestions for improving the effect of spin coating

- What are the special requirements for spin-coated nanoparticles?

- Detailed operation steps schematic diagram of the glue leveler

- Two different spin coating methods: dynamic dispensing and static dispensing

- Spin coatings spin coaters: principles, applications, functions and maintenance

- What is spin coating and how does it work?

- Spin-on cleaning and specific cleaning steps

- What is spin coating?

- What are the common problems of spin coating experiment?

- Common defects in spin coating of homogenizer

KW-4K

KW-4K