Pushen ISO-50um stainless steel double-channel Fineness Meter 0-50μm

Pushen ISO-50um stainless steel double-channel Fineness Meter is prepared with a wet film thickness of 0 to 50 microns. ISO-50um is made of stainless steel (40Cr13 forging), which has good wear resistance and is used to detect the fineness of particles such as Coating inks pigment.

Pushen

Pushen-

MODERNER QXD-25 small double-channel qxd Fineness gauge 25 micron particle Fineness gauge

Login -

TRUIT TR 1201/015 single-channe Coating Fineness gauge 0~15μm

$ 165.00 -

INKS Fineness gauge MODERNER QXD-100

Login -

QXD0-150 single-channe Fineness Gauge YONGLIDA 0-150μm detection range Cr12 molybdenum vanadium material

$ 125.00 -

TQC VF2123 wide-channel Grindometer Range 0-100µm with calibrated certificate

$ 1193.00

Introduction

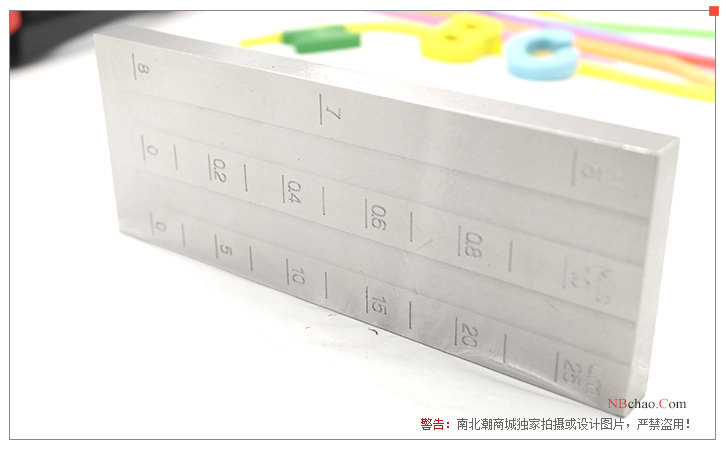

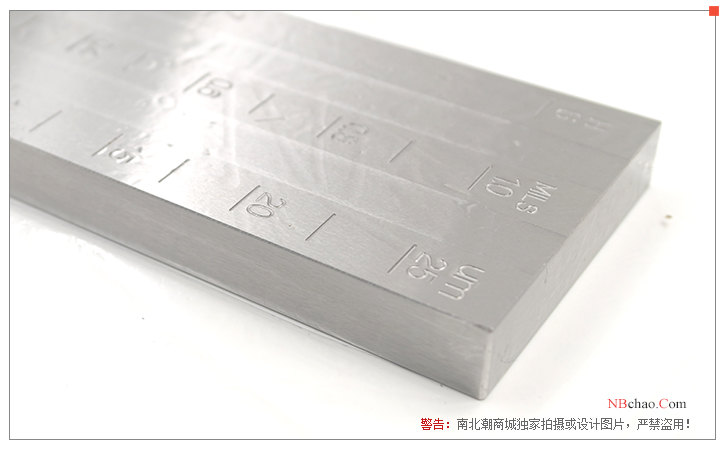

The double-channel Fineness gauge is a two-channel Fineness gauge, and the surface is represented by a scale of microns, Hegemann, and mils, and the brand name and product number of Purschen are engraved on the side of the double-channel Fineness gauge. This double-groove fineness gauge is equipped with a scraper, and the outer box of a black hard plastic tool box is used, and the inner fineness plate is coated with rust oil and wrapped in plastic film, and the packaging is delicate.The front roughness of the double-groove fineness gauge plate is 0.1 and the scraper roughness is 0.05.

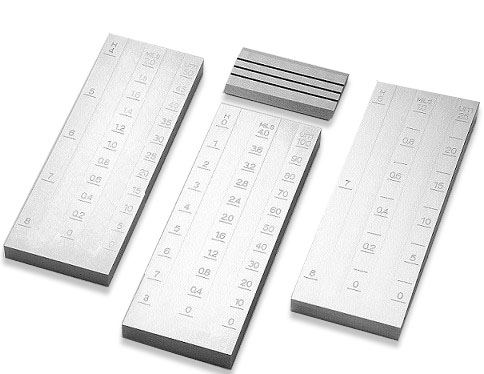

Pushen double-channel Fineness gauge has PU-2420,PU-2421、PU-2422 three models, the prepared wet film thickness is 0~25 microns respectively,0~50 microns, 0~100 microns, made of stainless steel (40Cr13 forging parts), good abrasion resistance, pushenDouble groove fineness gaugeIt is used to detect the fineness of particles such as paints, inks, pigments, etc.

Double groove fineness gaugeThe principle

The physical property of the dispersion is called "fineness", which depends not only on the actual size of the individual particles, but also on the degree to which they are dispersed. The ink Grindometer can be used to quickly measure the fineness of the paint.

Actual picture of the product

Application

Double groove fineness gaugeIn addition to the fineness of paints, it is also possible to determine the fineness of many materials such as coatings, pigments, raw materials, plastics, printing inks, etc. In the chocolate, ceramic, paper, food and other industries, the fineness of the product can also be tested with a coating double-groove Fineness Meter, and there are many other application areas.

Operating instructionsSuggested Reading:

![]() The operating instructions of the Pushen scraper Fineness Meter .pdf

The operating instructions of the Pushen scraper Fineness Meter .pdf

Pushen ISO-50um Double-channel Fineness of Ground GaugeSpecifications

| LIST | VALUE |

|---|---|

| Scraper type | double-channel |

| Number of grooves | 2 |

| range | 0 ~ 50µm |

| Scale unit | μm、Hegman、Mils |

| precision | ± 1.5µm |

| Scraper material | Stainless steel (40Cr13 forging) |

| Scraper size | 175*65*15mm |

| Applicable standard | GB/T 6753.1-2007 |

| Hardness | HRC50 ± 2 |

| Graduation | 5μm |

| Groove width | 12mm |

Pushen ISO-50um Double-channel Fineness of Ground Gauge Packing list

Scraper x1, doctor blade x1, instruction manual x1, plastic Encasement box x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Combined pencil Hardness Tester operating instructions

- Shanghai Pushen pushen film preparation instrument selection table [selection]

- Pushen KTQ Micrometer Film Applicator

- A good manual Ink Proofer from domestic (CN)

- IncomingGB/T 17001.3-2025

- ActiveHG/T 5173-2017

- ActiveWJ 2669-2005

- ActiveGB/T 42541-2023

- ActiveGB/T 17001.6-2022

- AbolishTB/T 2260-1991

- ActiveHG/T 5370-2018

- ActiveHG/T 5367.1-2018

- ActiveHG/T 5183-2017

- ActiveHG/T 5180-2017

- ActiveHG/T 5175-2017

- ActiveHG/T 3349-2003

- ActiveASTM D3794-2022

- ActiveJT/T 821.3-2011

- ActiveJT/T 821.1-2011

- ActiveASTM D1210-05-2022

- ActiveJB/T 9385-2017

- ActiveGB/T 1724-2019

- ActiveASTM D1316-2020

- ActiveGB/T 5211.17-1988

ISO-50um

ISO-50um

ISO-100um

ISO-100um

ISO-25um

ISO-25um