LEEB Leeb232 Coating Thickness Gauge magnetic Induction/eddy Current Range 0~1250μm

Magnetic Induction/eddy Current Thickness Measurement range 0~1250μm, thickness measurement accuracy +/- 3%, support single and continuous measurement.

Leeb

Leeb-

Defelsko FNTS thick coating probe 0~6mm/+/- 1%

$ 1328.00 -

LANDTEK Thickness Gauge probe 90 ° right angle iron based probe

$ 163.00 -

CHINA CTG-800-1500FN Paint Layer Thickness Gauge, Integrated dual-use Standard Type

$ 208.00 -

Defelsko PosiTector 6000 NAS3 Coating Thickness Gauge Aluminum oxide film

$ 1818.00 -

LANDTEK CM8826Fn paints Thickness Gauge, automatic substrate identification

$ 392.00

Overview

Using two measurement methods of magnetic and eddy current, the thickness of the non-magnetic covering layer on the magnetic metal substrate (such as aluminum, chromium, copper, zinc, tin, rubber, paint, etc.) can be detected, and the thickness of the non-conductive insulating covering layer on the non-magnetic metal substrate (such as aluminum, copper, zinc, rubber on tin, plastic, paint, oxide film, etc.).

Coating Thickness Gauges are used in electroplating, anti-corrosion, aerospace, aviation, chemical industry, automobile, shipbuilding, light industry, commodity inspection and other testing fields. It can be used in both laboratories and engineering sites. Equipped with different probes, it is suitable for different occasions. It is an essential instrument in the testing industry.

Main function

● There are two measurement methods: continuous measurement and single measurement method;

● There are two Operating Modes: direct and group mode;

● With automatic statistics function: average value (MEAN), maximum value (MAX), minimum value (MIN), number of tests (NO.), standard deviation (S. DEV);

● The instrument can be calibrated by two methods: single-point calibration and two-point calibration, and the systematic error of the probe can be corrected by the basic calibration method;

● Storage function: 4 correction workpieces can be stored. 26 groups of each type, 15 in each group, with a total of 1560 measured values;

● Delete function: delete a single suspicious data that appears in the measurement, and also delete the data in the storage area for new measurements;

● Set the limit: the measured value outside the limit can be automatically alarmed;

● With power underVoltage indication function, there is a beep prompt during operation, and the automatic shutdown mode.

● Metal shell: The fuselage material is aviation aluminum metal shell, which has low anti-interference and wear.

Meet the standard

1. GB/T 4956 ─ 1985 Measurement of thickness of non-magnetic coating on magnetic metal substrate, magnetic method

2. GB/T 4957 ─ 1985 Measurement of thickness of non-conductive coating on non-magnetic metal substrate, eddy current method

3. JB/T 8393 ─ 1996 Magnetic and eddy flow coating thickness measuring instrument

4. JJG 889 ─ 95 "Magnetoresistive Thickness Gauge"

5. JJG 818 ─ 93 "Eddy Current Thickness Gauge"

Measurement principle

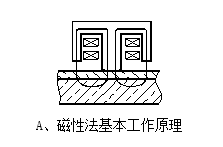

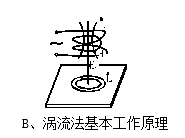

This instrument adopts the thickness measurement method of magnetic principle, which can measure the thickness of non-magnetic coating layer (such as aluminum, chromium, copper, enamel, rubber, paint, etc.) on magnetic metal matrix (such as iron, cobalt, nickel). The measurement principle of eddy current is also used to measure the thickness of non-conductive coating layer (such as enamel, rubber, paint, plastic, etc.) on non-magnetic metal matrix (such as copper, aluminum, zinc, tin, etc.).

A. Magnetic method (F-type probe): When the probe is in contact with the cover layer, the probe and the magnetic metal substrate form a closed magnetic circuit. Due to the existence of the non-magnetic cover layer, the magnetic circuit magnetoresistance changes. The thickness of the cover layer can be measured by the amount of change.

B. Eddy current method (N-type probe): use high-frequency alternating current to generate an electromagnetic field in the coil. When the probe is in contact with the cover layer, an eddy current is generated on the metal substrate, and the coil in the probe is generated. Feedback effect, the thickness of the covering layer can be derived by measuring the magnitude of the feedback effect.

Leeb Leeb232 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Probe Type | F1/N1 |

| Working Principle | Magnetic Induction/eddy Current |

| Measurement range | 0~1250μm |

| Low resolution | 0.1μm |

| A little indication of calibrating error | ±(3%H+1) |

| Two-point indication of calibrating error | ±[(1~3%)H+1] |

| Minimum radius of curvature | Convex 1.5mm, Concave 9mm |

| Minimum area diameter | Φ7mm |

| Basic critical thickness | 0.5mm |

| temperature | 0~40℃ |

| Humidity | 20%~90% |

| Power | AA type alkaline battery 1.5V two |

| Dimensions | 130 × 70 × 25Mm (host) |

| Weight | 350g |

| Shell material | Metal shell |

| optional | Standard test piece, probe, pc communication |

Leeb Leeb232 Coating Thickness Gauge Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application, Principle Introduction and Precautions for Selection of Pipeline Thickness Gauges

- Principle and Application Analysis of Silver Plating Thickness Gauge

- Basic principle and application scenario of steel Coating Thickness Gauge

- Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- Principle, application and selection of stainless steel paints Coating Thickness Gauge

- Principle, application and selection of traffic coatings Coating Thickness Gauge

Leeb232

Leeb232

Leeb231

Leeb231