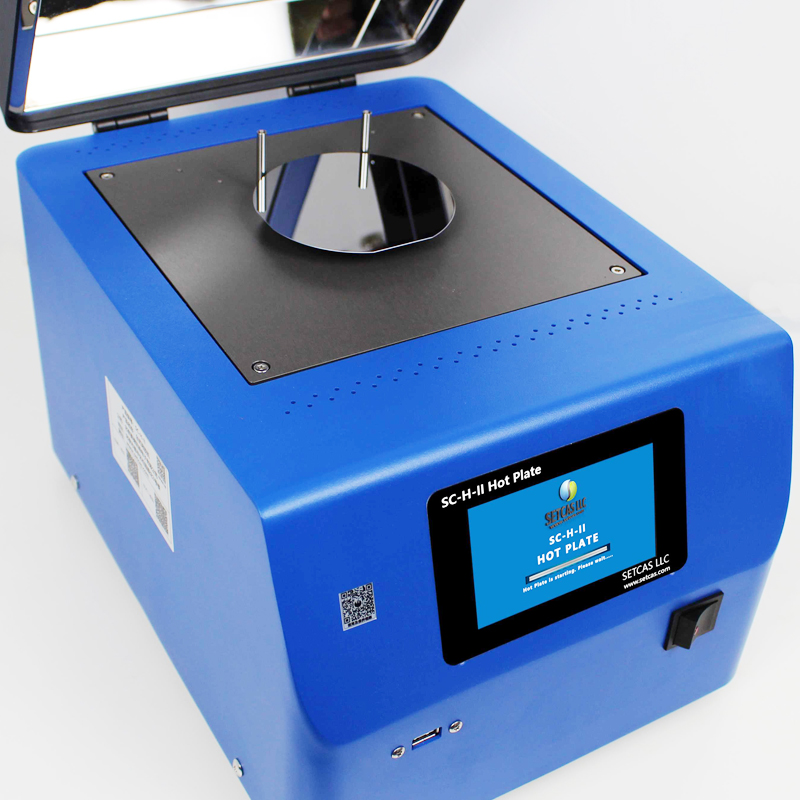

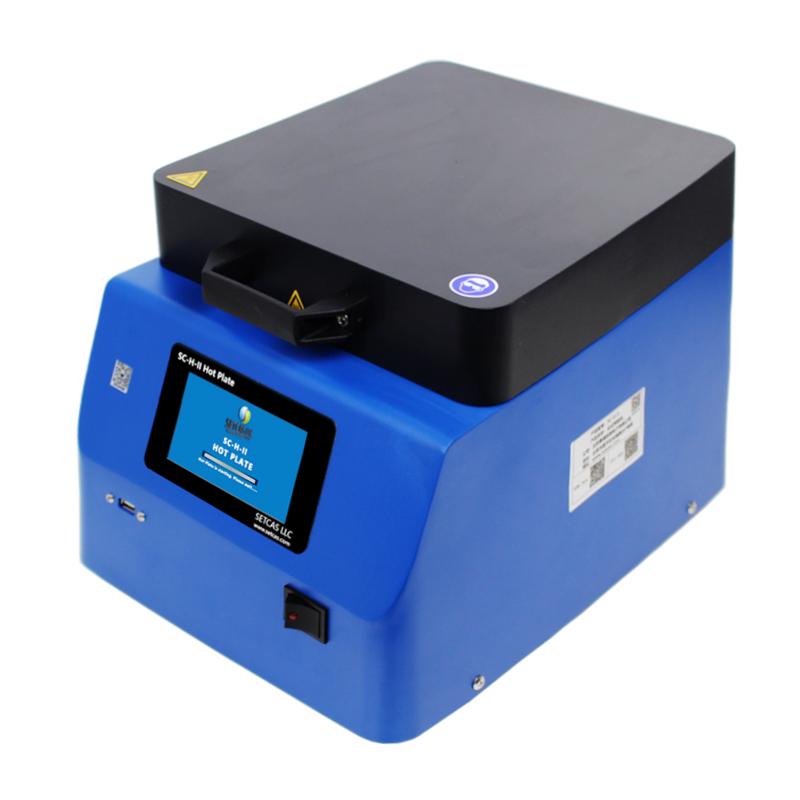

SETCAS SC-H-II Nitrogen Filling Roasting Machine (with jacking) Room Temperature -450 ℃

Temperature range RT+ -450 ℃, temperature control continuously adjustable, Heating Plate size 200 × 200mm, with jacking, can pass nitrogen, can be vacuumed, can be set to rise Linear dispersion.

Setcas

Setcas-

Chengyue CY-SPC4-PTFE spinning Coater miniaturized design 10000 rpm, program-controlled homogenizer

$ 2045.00 -

CHINA 12Az laboratory Spin Coater, four-stage speed, LCD screen

$ 1114.00 -

SETCAS KW-4L-I automatic glue dispenser, high-end

Login -

SETCAS SC-CD-I homogenizer, automatic glue coating machine

Login -

CHINA 12E spin coating machine, touch screen, test spin coating machine

$ 1461.00

Introduction

The SC-H-II glue baking machine is equipped with a jack, can pass nitrogen, can be evacuated, and can be set to a rising curve. It is suitable for semiconductor silicon wafers, glass slides , wafers, substrates, ITO conductive glass and other processes. After the surface of the plate is coated, the film is dried and solidified. The Hot Plate has high temperature stability and good repeatability. Used for production, scientific research and teaching in industrial and mining enterprises, scientific research, education and other units.

Product main features

1. The stability performance is very good, and the temperature stability can reach ±0.5℃.

2. Wide temperature adjustment range: room temperature -450℃.

2. Adopt closed-loop control and heat up quickly.

3. With timing function. It also has a countdown display function.

4. Use digital buttons to control temperature and time, making temperature and time settings more accurate.

5. The body is all made of stainless steel, which is acid, alkali and corrosion resistant.

6. Provide Heating Plate customization services according to the size of the customer's substrate.

Setcas SC-H-II Glue BakerSpecifications

| LIST | VALUE |

|---|---|

| Formulation can be set | 10-Stage, N-group formula |

| Peripherals | The formula can be exported, and an external mouse and keyboard can be connected. |

| Thermostatic fluctuation | ±0.5℃ |

| Temperature Uniformity | +/- 1% (Temperature Uniformity throughout the table at maximum temperature) |

| jacking range | 0-30Mm, can be positioned arbitrarily |

| nitrogen pressure | 0.2-0.8MPA |

| Heating plate size | 200×200mm |

| Instrument size | 210×220×160mm |

| Weight | 6.5KG |

Setcas SC-H-II Glue Baker Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Common Problems and Maintenance Measures of Spin Coater of Gluer

- What are the common problems of spin coating experiment?

- Two different spin coating methods: dynamic dispensing and static dispensing

- Detailed operation steps schematic diagram of the glue leveler

- What are the special requirements for spin-coated nanoparticles?

- Common defects in spin coating of homogenizer

- What is spin coating?

- Spin-on cleaning and specific cleaning steps

- How does the automatic glue dispenser carry out liquid injection to the dripping point and the specific operation method?

- Four key stages of spin coating

SC-H-II

SC-H-II