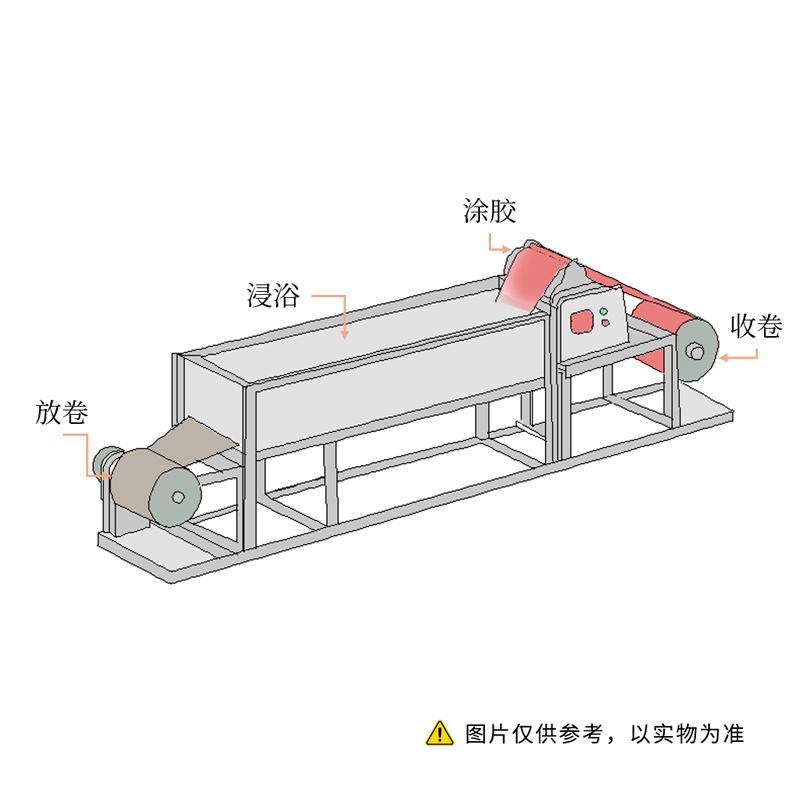

Coil Glue Coater Rgd-00/350TSDC Double Sided Coil Film Applicator Soaking + Double top coating cloth

Spreader process unwinding → soaking → double-sided extrusion Spreader → transverse slitting, Spreader method double top coating cloth, film accuracy +/- 5%, Graduation 0.001mm, Coating speed adjustable 0~20m/min, effective application width ≤ 350mm

Factory

Factory-

Oven coil composite Coater with unwinding + scraping + drying + covering + winding function

$ 15859.00 -

Factory Direct Rjy-00/1000 immersion type Coater dip coating double roll extrusion equipment, effective width 1000mm

$ 31646.00 -

Automatic Film Applicator RDH-12/650cl film width 650mm unwinding + comma scraping + infrared drying + comma scraping + infrared Drying Oven + air-cooled + winding

$ 50590.00 -

CHINA NBC-XF500 pet slot die roll to roll Film Applicator Spreader Width 500mm

$ 60062.00 -

CHINA Micro Coil Automatic Spraying and Coating Machine TBJ-JCPT-DJ1 Customized

$ 19016.00

Structure of double-sided coil coating machine

The machine is composed of a body, a gluing width adjustment device, a discharging rack, a gluing roller group, a thickness adjustment dial gauge, a transmission platform, a traction roller group, and a transmission mechanism.

Introduction to the structure and composition functions

Body:The body of the equipment is all aluminum alloy + stainless steel plate.

Gluing width adjustment device:The width adjustment device consists of food-grade plastic and a movable brace.

Unwinding rack:The machine is equipped with two unloading racks, when the two materials do not deviate from the material pair in the laminating process, the deviation correction device automatically adjusts the material rack to move left and right to achieve the effect of aligning the two materials.

Transmission platform:The transmission platform is made of stainless steel, and its main function is to connect the substrate after gluing to the next process.

Traction roller set:The substrate is pulled by hand between the upper and lower rollers of the traction roller, the handwheel on the frame is tightened to make the traction roller, and the rubber ring of the upper roller is in contact with the lower roller, and the traction roller group is drawn over to the substrate by power transmission to make the coating work complete.

Factory Rgd-00/350TSDC Double Sided Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Spreader process | Unwinding → Soaking → Double Sided Extrusion Spreader → Transverse Slitting |

| Coating method | Double top coating cloth |

| Thickness range | 0.001-3mm |

| Film Accuracy | ±5% |

| Graduation | 0.001mm |

| percentile | digital display |

| Coating speed | 0~20M/min adjustable |

| Effective application width | ≤350mm |

| Roll surface length | 350mm |

| Unwinding outer diameter | Max. Ф350mm |

| winding outer diameter | Max. Ф350mm |

| Outer diameter of winding air expansion shaft | 3-Inch expansion shaft, load-bearing 50KG |

| Winding outer diameter range | ≤350mm |

| Bath size | 500*400*500mm |

| gas source | 0.5~ 0.8MPa compressed air |

| tension control | Max.60N |

| Control mode | automatic |

| Correction Accuracy | ±1mm |

| Slitting blade | straight knife slitting |

| cutting direction | transverse slitting |

| slitting length | Cut the coil into sheets according to the preset length |

| Edge trimming | Cut off the irregular part of the edge of the roll |

| Applicable coil type | Plastic film, metal foil, paper, non-woven fabric, etc |

| Spreader type | Water-based paints, solar-based paints, UV coatings, etc |

| Environmental temperature | 10℃ ~ 40℃ |

| Environmental humidity | ≤70% RH |

| Host Power Supply | 380V/2KW |

| Dimension | 2280 * 680 * 1600mm (subject to actual customization) |

| Weight | 1 ton (subject to actual customization) |

Factory Rgd-00/350TSDC Double Sided Film Applicator Packing list

Film Applicator x1, film device x1, slitting device x1, unwinding device x1, deviation correction device x1, immersion tank x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rgd-00/350TSDC

Rgd-00/350TSDC