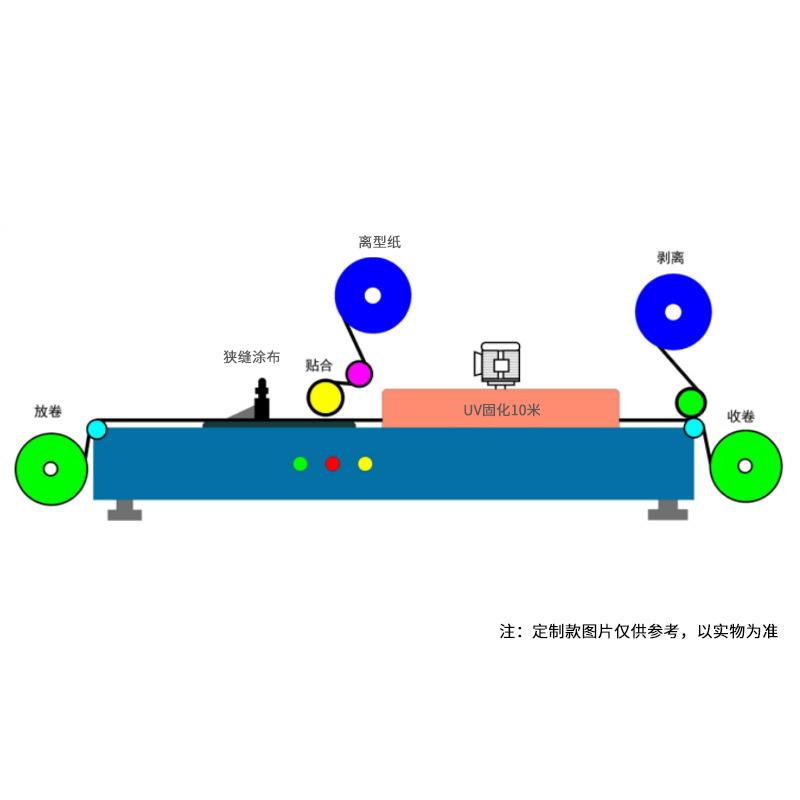

Rxf-10/1600UV Pilot Coil Automatic Film Applicator Scratch + Lamination + UV curing + disbonding

Spreader process unwinding → scraping → bonding → UV curing → disbonding → winding, film accuracy +/- 10%, Coating speed 50~80 m/min, effective application width φ 100~1600mm, unwinding diameter φ 600mm, winding diameter φ 600mm, winding method Release paper/film winding.

Factory

Factory-

Factory Direct Rva - 0.5/300 Pro Roll to Roll Micro Concave Film Applicator Desktop Precision Spreader Test Line

$ 23752.00 -

CHINA Rgd-01/400TS Double-sided Coil Film Applicator Double roller painting cloth, effective application width 400mm belt correction device

Login -

Oven coil composite Coater with unwinding + scraping + drying + covering + winding function

$ 15859.00 -

Automatic Film Applicator with rolling + scraping + drying + winding function application width 800mm

Login -

Pilot-scale coil automatic film laminating machine, with unwinding + scraping + drying + film laminating + deviation correction + winding function application width 750mm

$ 23752.00

Rxf-10/1600UV automatic coating machine for medium test rolls, integrating unwinding, scraping, laminating, UV curing, peeling, and winding, to achieve efficient automatic coating.

Core Benefits:

Adjustable width for precise application

The effective coating width Φ100 - 1600mm can be adjusted to meet the needs of different sizes; The coating film accuracy ± 10% to ensure a uniform coating.

High-speed, stable, efficient production

Coating rates of 50 - 80 m/min, with a minimum of 50 m/min, increase productivity.

Slit coating, precise control

Slit coating with adjustable coating weights from 20 to 100 g/m² to meet different process requirements.

Intelligent control, easy to operate

Equipped with automatic tension and deviation correction control, PLC control system and touch screen operation interface, it realizes intelligent operation and reduces labor costs.

Widely applicable and multi-application

It can handle a variety of coils such as plastic films and coating solutions such as water-based paints, and is suitable for a wide range of fields such as packaging, printing, and electronics.

Factory Rxf-10/1600UV Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Spreader process | Unwinding → scraping → bonding → UV curing → disbonding → winding |

| Effective application width | φ 100~1600mm (adjustable) |

| Film Accuracy | ±10% |

| Coating speed | 50 to 80 m/min (minimum guaranteed 50 m/min) |

| Coating method | Slot-die Spreader |

| Spreader Range | 20~100 g/m² |

| Fitting method | Roll fit |

| Fitting speed | 1~10m/min |

| Fitting Accuracy | 0.5mm |

| Fitting pressure | 0.1~ 0.5 MPa (adjustable) |

| Fit width | φ 100~1600mm adjustable |

| Roll surface length | 1600mm |

| unwinding method | Release paper/film unwinding, double station automatic paper connection |

| substrate unwinding | Single station, equipped with automatic correction system |

| maximum discharge | Φ1600mm |

| unwinding diameter | Φ600mm |

| winding diameter | Φ600mm |

| winding method | Release paper/film winding, finished product winding, independent winding |

| UV Lamp Power | Spreader speed and material curing requirements |

| UV light source | LED |

| Outer diameter of winding air expansion shaft | 3-Inch expansion shaft, load-bearing 50KG |

| tension control | automatic control |

| Correction control | automatic control |

| Control system | PLC control, Touch screen Operating interface |

| thickness control | manual control |

| gas source | 0.5~ 0.8MPa compressed air |

| Emergency stop button | √ |

| Warning sign | √ |

| Applicable coil type | Plastic film, metal foil, paper, non-woven fabric, etc |

| Spreader type | Water-based paints, solar-based paints, UV coatings, etc |

| Environmental temperature | 10℃ ~ 40℃ |

| Environmental humidity | ≤70% RH |

| power requirements | 380V, 50Hz, three-phase five-wire system |

| Machine Weight | 2 tons (subject to actual customization) |

| Dimension | 13000mm*2000mm*1800mm (subject to actual customization) |

Factory Rxf-10/1600UV Automatic Film Applicator Packing list

Host x1, Manual x1, Encasement List x1, Certificate of Conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

Rxf-10/1600UV

Rxf-10/1600UV