MODERNER STM-V + P Stormer Viscometer with printer, testing paints and Miscellaneous Coating viscosity expressed in KU

MODERNER STM-V + P Stormer Viscometer is a digital display Stormer Viscometer for Coating viscosity testing, STM-V + P Viscometer LCD display KU value, with printer.

Moderner

Moderner-

FANGRUI STM-2T Stormer Viscometer Viscosity Range 40.2~ 141.0KU

$ 649.00 -

PUSHEN STM-IV Stormer Viscometer KU/G

$ 581.00 -

STM-IV Digital Stormer Viscometer YONGLIDA 40.2KU~ 141.0KU Viscosity Range

$ 771.00 -

TQC Sheen DV2300 Krebs Viscometer Stormer Viscometer Coating KU Viscometer

$ 7538.00 -

PUSHEN STM-IVB Stormer Viscometer KU/G/CP

$ 609.00

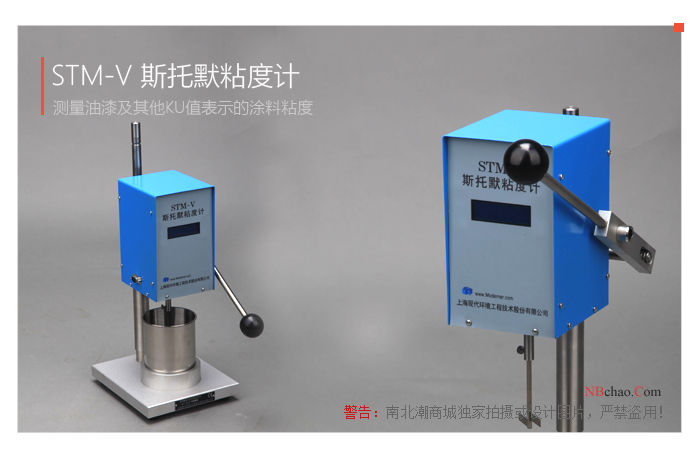

Introduction to STM-V Stormer Viscometer

MODERNER STM-V Stormer viscometer is a digital display Stormer viscometer. The control head is a blue metal shell with a handle on the side. The lower part of the control head is connected to a stirring paddle. The viscosity measurement is achieved by computer-controlled rotation of the stirring paddle. , and a display screen displays the measured viscosity value.The measuring viscosity range of the STM-V Stormer viscometer is 40.2KU~141.0KU.

The STM-V Stormer Viscometer is a testing instrument used to measure the viscosity of paints and other coatings with a KU value. The LCD simultaneously displays the KU value of the sample being tested and the load value (unit: g) and reference viscosity value (unit: cP) associated with the KU value.

The Stormer viscometer is microcomputer controlled and has a serial print port. The operator only needs to immerse the stirring blade into the sample to be measured to the specified depth, and the KU value and associated load value of the sample can be read directly from the STM-V Stormer viscometer . Stormer viscometer is designed based on the GB9269 standard

Stormer Viscometer Product Picture

Usage environment of STM-V Stormer viscometer

(1) MODERNER STM-V Stormer viscometer should be placed on a solid and flat table away from strong air flow, strong magnetic field, strong electric field, and strong electromagnetic pulse interference.

(2) The temperature in the laboratory should be 25℃±2℃, and the Relative Humidity should not be greater than 75%.

(3) The sample temperature should be 25℃±0.2℃.

Operation and use of STM-V Stormer viscometer

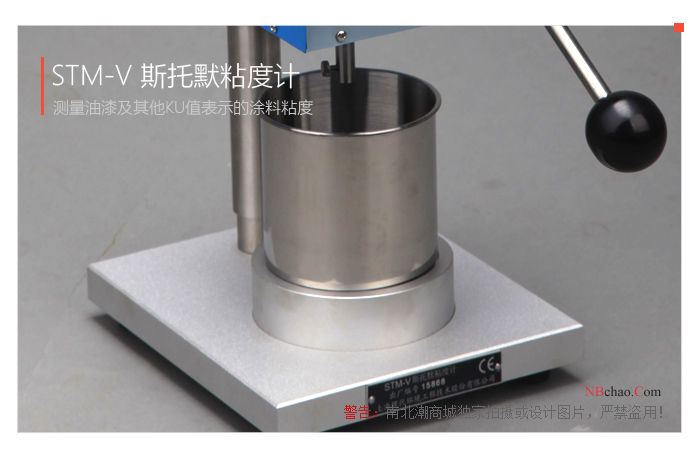

(1) Take the STM-V Stormer viscometer out of the packaging box and place it on the workbench.

(2) Take out the lifting handle from the packaging box, screw its threaded part into the screw hole on the connection block on the right side of the Modern Environment STM-V Stormer Viscometer , and tighten it firmly.

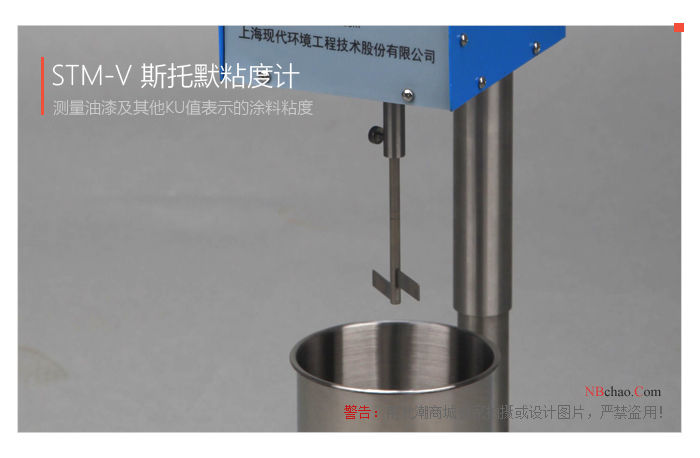

(3) Take out the mixing blade from the packaging box, insert it into the sleeve of the rotating shaft according to the outline diagram, and fix it with a set screw. Note that the set screw should be against the flat mouth of the mixing blade.

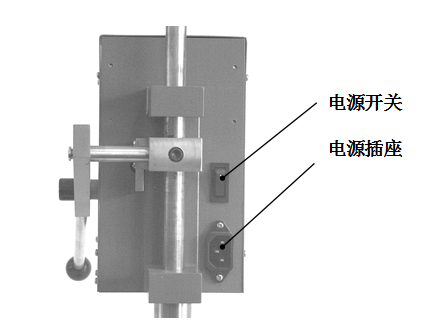

(4) Plug in the power plug and turn on the power switch located at the rear of the instrument (refer to the rear panel diagram). The STM-V Stormer viscometer starts self-test. The name of the production company, website, instrument model name, and instrument sequence appear first. No. and factory date and other startup-related company information, and then "The motor has not rotated yet, please press the handle!" appears, indicating that the instrument is working normally. The next step is to immerse the paddle in the liquid to be measured.

(5) Place the sample to be measured into the container that comes with the STM-V Stormer viscometer . Note that the distance between the liquid level of the sample to be measured and the mouth of the container is about 19mm. The liquid level cannot be too shallow, otherwise the liquid level will not reach the scale line of the blade, which will increase the measurement error.

(6) Place the container containing the sample to be tested on the container holder, press the lifting handle, and immerse the stirring blade into the sample to be tested. The mark on the stirring blade shaft is flush with the liquid level. At this time, the blades rotate immediately, and the words "Data is being processed, please wait...9s" appear on the display screen. Every second, 9s will automatically decrease by 1 until 0 seconds. After the data processing is completed, the "KU value" (first line) of the sample under test and the measured values ââ"load value" and "cP value" will be displayed on the display. "(second line).

(7) After the measurement, lift the lifting handle to a high place. There is a limit device near the highest position to keep the instrument in this position. The STM-V Stormer Viscometer stops rotating and re-enters standby mode.

(8) If the viscosity of the sample being measured (such as pure water) is lower than the measurement range of this STM-V Stormer Viscometer , that is, less than 40.2KU (equivalent to a 32g load value), the STM-V Stormer Viscometer "Your sample does not reach the measurement range of this instrument" will be displayed, followed by "000.0KU (first line) 0000g 0000cP (second line),"; when the viscosity of the sample being measured exceeds the measurement range of this instrument, the viscosity Greater than 141.0KU (equivalent to 1099g load value), the STM-V Stormer viscometer will display "Your sample has exceeded the measurement range of this instrument", and then display "888.8KU (first line) 8888g 8888cP (second line) OK)". Once this happens, the handle should be lifted immediately to stop the motor, otherwise the hairspring will be damaged for a long time.

Calculation formula

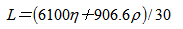

ããConversion of viscosity value and load value: Use the following formula to convert the viscosity value expressed in Pa·s into a load value expressed in grams, thus obtaining a load value of 200r/min for each oil.

In the formula: - viscosity of oil, Pa·s;

ââThe density of oil;

ã ââThe load value that produces a rotation speed of 200r/min, g.

Precautions

(1) This STM-V Stormer viscometer has precision measurement components inside the case, which should be handled with care when handling.

(2) This STM-V Stormer Viscometer is a special instrument. If you are not a professional, please do not disassemble the instrument case yourself to avoid affecting the measurement accuracy of the STM-V Stormer Viscometer .

(3) When the instrument is not in use temporarily, the lifting handle of the STM-V Stormer Viscometer should be kept on the high-position limiter and should not be placed in a lower position, otherwise the lift may become inflexible.

(4) The viscosity value of the coating being measured changes very sensitively with temperature. Therefore, when repeatedly measuring the viscosity value of the same sample, it is necessary to ensure that the sample temperature difference during each measurement is less than 0.2℃, and the height error of the blade immersed in the liquid surface each time is less than 0.5mm.

(5) It should be calibrated regularly once a year.

Print operation

(1) This STM-V Stormer viscometer is optionally equipped with a printer, which needs to be ordered separately.

(2) Connect the printer-related connections, turn on the power, and press the handle. After the STM-V Stormer viscometer displays that the parameters are stable, you can see "LPT" on the LCD to indicate that the printer has been connected. At this time If you lift the handle, you can print the relevant data.

(3) The printing paper is thermal printing paper, printing on plain paper is invalid.

(4) Printer power supply 220V 50Hz

Moderner STM-V+P Stormer ViscoMeterSpecifications

| LIST | VALUE |

|---|---|

| Display mode | digital display |

| Measurement range | 40.2~141.0KU,32~1099g,27~5274cP |

| Unit display | KU/g/cP |

| Reproducibility | ±1%F.S |

| Accuracy | ±5%F.S |

| Power | 220V/50Hz |

| Interface | serial print port |

| Applicable standards | GB/T 9269 |

| Dimensions | 210*180*500mm |

| Instrument Weight | 10kg |

| Swirl/spin speed | 200rpm |

| Container size | 500ml |

| Sample temperature | 25℃±0.2℃ |

| Working Relative Humidity | ≤75% |

| Lifting method | Lever lift |

Moderner STM-V+P Stormer ViscoMeter Packing list

host x1, stainless steel cup x1, manual x1, certificate x1, warranty card x1, printer x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 5776-2020

- ActiveHG/T 3951-2007

- ActiveASTM D562-01-2023

- ActiveASTM D 562-2018

- AbolishGB/T 9269-1988

- ActiveGB/T 9268-2008

- AbolishGB/T 9268-1988

- ActiveGB/T 9269-2009

STM-V+P

STM-V+P