MITECH MUT550B Digital Ultrasonic Flaw Detector with multiple Probe types

MITECH MUT550B digital Ultrasonic Flaw Detector adopts true color LCD screen, large range 0-9999mm, MUT550B is suitable for manufacturing, iron and steel industry, metal processing industry, chemical industry and other conventional defect detection needs

mitech

mitech-

IPRE UF180 Ultrasonic Flaw Detector nondestructive flaw detection machine 0~9999mm

$ 1658.00 -

RUNJIE RJTS800S digital Ultrasonic Flaw Detector, Speed of sound 1000~9999m/s

$ 1605.00 -

LEEB leeb610A Portable Yoke Flaw Detector Magnetization Pole Distance 0~220mm

$ 571.00 -

RUNJIE CDX-3 Magnetic Particle Flaw Detector Portable nondestructive testing instrument

$ 635.00 -

MITECH CDX-ⅲ Magnetic Particle Flaw Detector Multifunctional Magnetic Particle Flaw Detector Defect Detection

$ 416.00

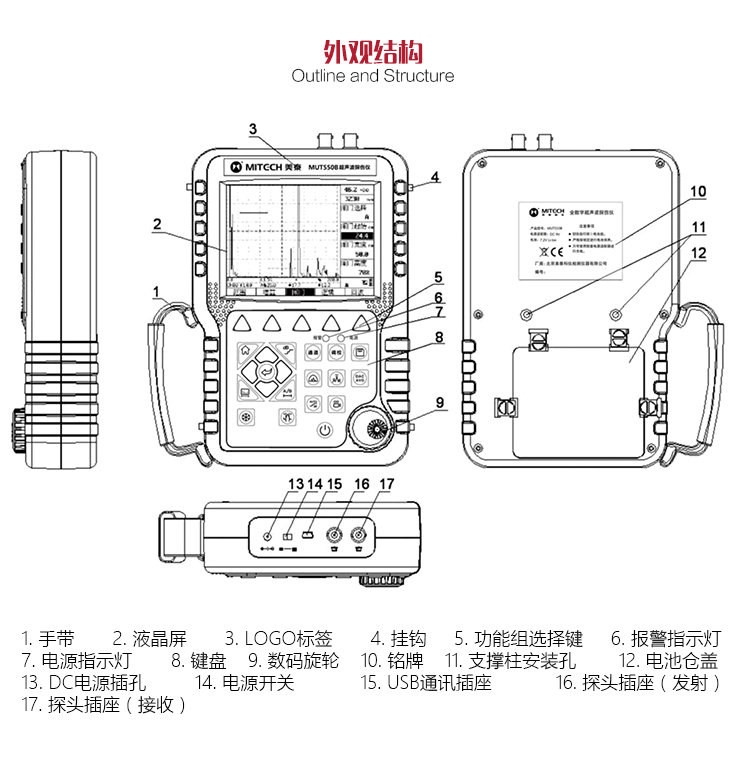

Overview

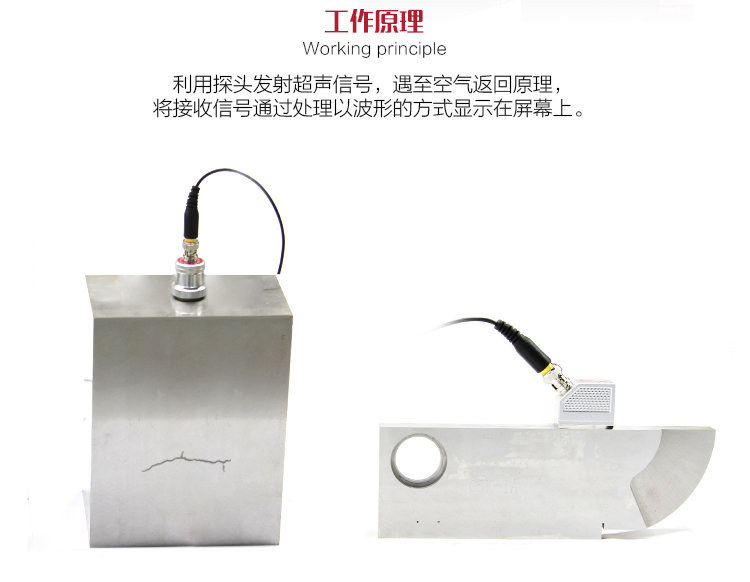

Mattel Instruments MUT550B digital ultrasonic flaw Detector is based on the principle of ultrasonic propagation, which can accurately and sensitively detect, locate, evaluate and diagnose a variety of defects (cracks, inclusions, porosity, etc.) inside the workpiece. The all-digital TFT640×480 true color LCD display can present clear defects for you in dim light and strong sunlight environments; The large range of 0-9999mm can meet the conventional defect detection needs of manufacturing, iron and steel metallurgy, metal processing industry, chemical industry, etc.; The low-power design is equipped with a large-capacity and high-performance lithium-ion battery module, which can work continuously for more than 10 hours; The full Chinese master-slave menu, focusing on user experience, integrates three operation modes: shortcut buttons, digital shuttle rotary wheel, and cross menu, and can be operated freely by different usage habits; It is equipped with a comprehensive performance index self-test function, which can automatically generate test reports and support multiple languages. This product has a high price-performance ratio and is a smart choice for practical and economical ultrasonic testing instruments.

Functional use

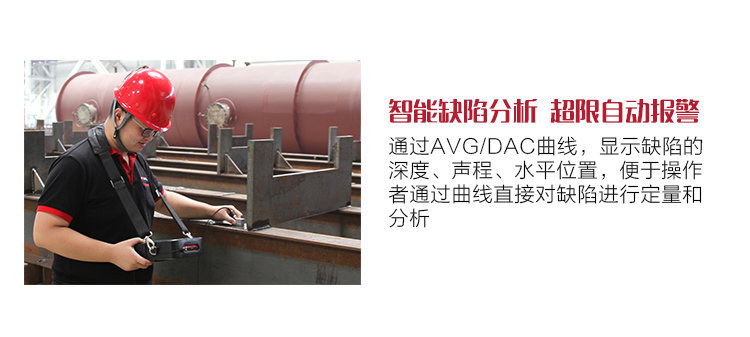

MUT550B digital ultrasonic flaw DetectorIt can be widely used in manufacturing, iron and steel metallurgy, metal processing industry, chemical industry and other fields that require defect detection and quality control, and is also widely used in aerospace, railway transportation, boiler and pressure vessel and other fields of in-service safety inspection and life assessment.

Features

1. MUT550B digital ultrasonic flaw DetectorDesigned for harsh field environments and rugged. The sealed design allows it to withstand moisture, wind, sand and dust in harsh environments from the ocean to the desert.Oil and other pollution. Unique spill-proof design, waterproof and oil-proof, can work in rainy days. The unique swivel stand is easy to use.

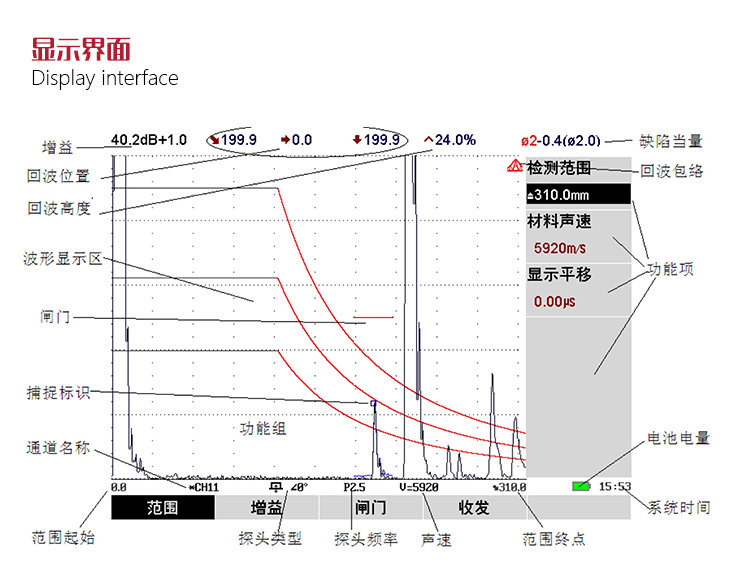

2. The defect echo parameters (distance, horizontal, vertical, amplitude, dB equivalent value, flat bottom hole equivalent value) are displayed in real time, the flaw detection information is clear at a glance, and the flat bottom hole conversion of defect quantification can be automatically completed.

3. Square wave pulse, emission Voltage, filter frequency band, and probe damping are adjustable, which is suitable for flaw detection of various workpieces.

4. Full Chinese display, master-slave menu, and designed with shortcut buttons and digital shuttle rotary wheel, easy to operate, professional technology.

5. Using TFT all-digital true color LCD display, the resolution of the LCD is 640X480 The screen brightness is clear, the background color can be selected according to the environment, and the LCD brightness can be set freely, so that it can adapt to different operating environments.

6. The high-performance security battery module is easy to disassemble and assemble, so that the continuous working time of the instrument can reach more than eight hours.

mitech MUT550B Ultrasonic Flaw DetectorSpecifications

| LIST | VALUE |

|---|---|

| Scanning range | 0~9999mm |

| Frequency range | 0.2~20MHz |

| Speed of sound | 300~20000m/s |

| Dynamic range | ≥36dB |

| Vertical Linearity | ≤2% |

| Horizontal Linearity | ≤0.1% |

| Display | 640X480 true color LCD screen |

| resolution | >40dB(5P14) |

| Blind spot | 5MM |

| digital suppression | (0~80) %, does not affect linearity and gain |

| video duration | More than 10 hours |

| electrical noise level | ≤8% |

| Probe type | Straight probe, oblique probe, dual crystal probe, penetration probe |

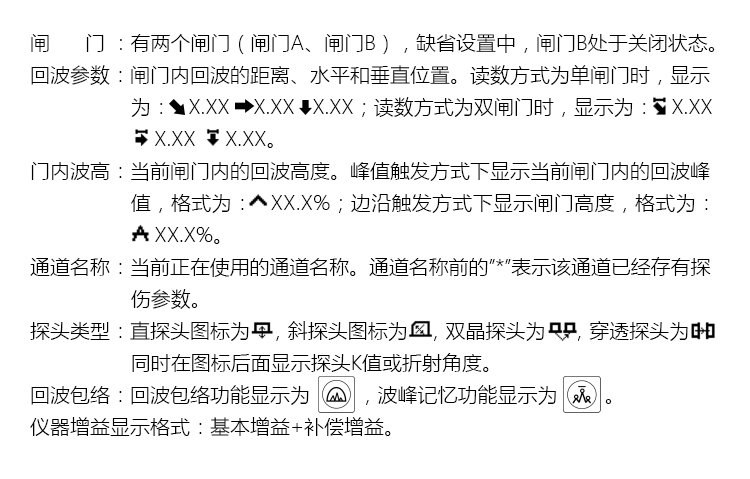

| gate | Inlet gate, loss gate; single gate reading, double gate reading |

| Alarm function | Beep alarm, LED light alarm |

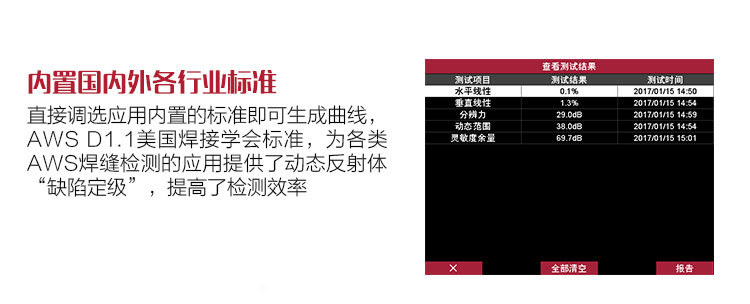

| flaw detection standard | Built-in common flaw detection standards in various industries, directly calling, convenient and fast |

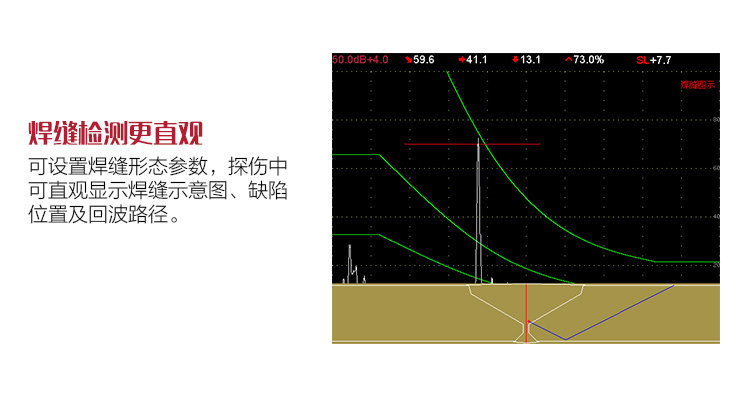

| Weld diagram | The weld shape parameters can be set, and the weld pattern and the position of defects in the weld can be visually displayed during flaw detection |

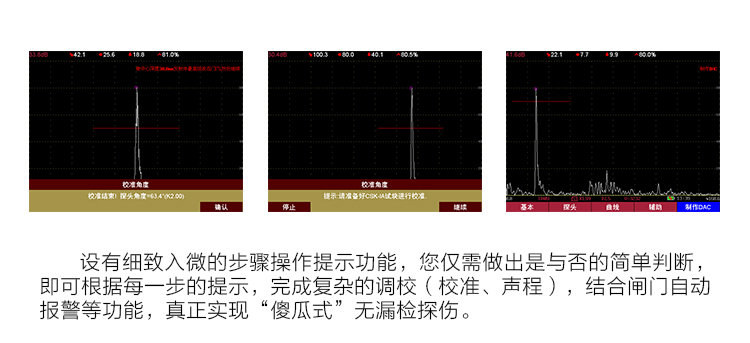

| Automatic calibration | Probe zero and probe angle (K value) Automatic calibration function; Speed of sound automatic measurement function |

| Memory | Real-time retrieval of the highest defect wave and recording of the peak defect echo |

| positioning | Real-time display of defect horizontal, depth (vertical), sound path position |

| defect quantification | Real-time display of defect equivalent dB value |

| defect characterization | Through the echo envelope waveform, it is convenient for manual experience to judge |

| surface correction | For flaw detection of curved workpieces, it can display the circumferential position and depth of defects in real time |

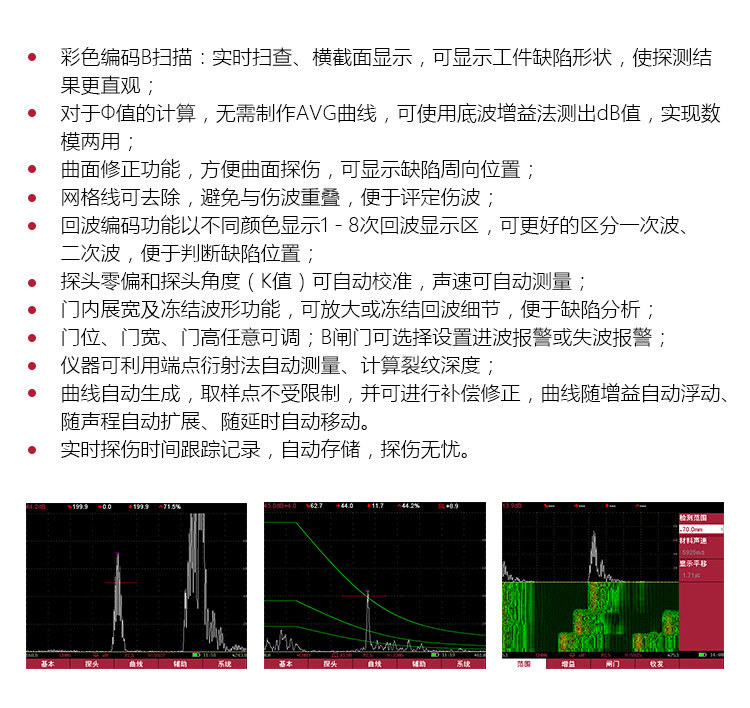

| DAC/AVG | Linear dispersion is automatically generated, with unlimited sampling points, and can be compensated and corrected. Linear dispersion automatically floats with gain, automatically expands with sound path, and automatically moves with delay. AVG Linear dispersion can display any aperture |

| AWS D1.1 | American Welding Society standard, provides a dynamic reflection "defect rating" for various AWS weld inspection applications. Avoids manual calculations and improves inspection efficiency. (optional) |

| Crazing bathymetry | Automatic measurement and calculation of crazing depth using diffraction waves |

| Door widening | Amplify echo details for easy echo analysis |

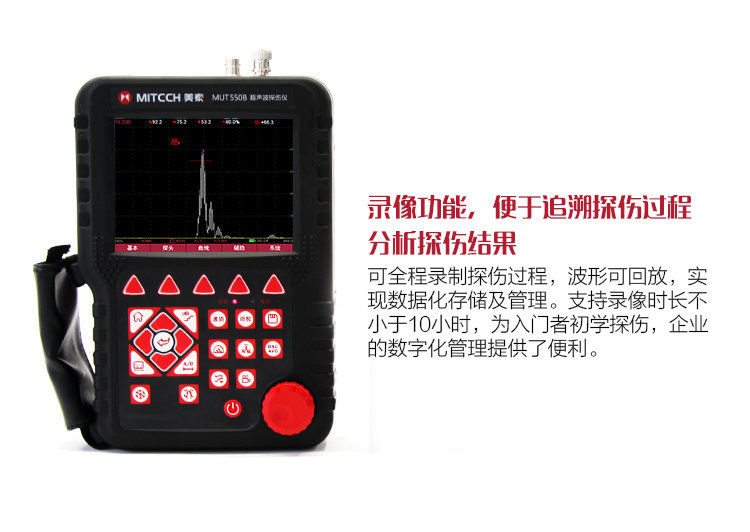

| continuous recording | Real-time waveform recording, storage, playback |

| waveform freezing | Freeze the waveform displayed on the screen for easy defect analysis |

| echo coding | Display 1 to 6 echo display areas in different Colors, better distinguish between primary and secondary waves, and facilitate the determination of defect locations |

| B-scan | (Color-coded B-scan) Real-time scanning and cross-sectional display make detection results more intuitive |

| Environmental temperature | (-10~50)℃ |

| Relative Humidity | (20~95)%RH |

| Power Supply | Direct current (DC) 9V; lithium battery works continuously for more than 10 hours |

| Power saving method | Low power design |

| Working time | More than 10 hours |

| Protection level | IP64 |

| Communication interface | USB2.0 high-speed communication transmission interface |

| PC software | Yes. |

| Operating language | Chinese |

| Dimension | 263*170*61mm |

| Machine Weight | 5.2KG |

mitech MUT550B Ultrasonic Flaw Detector Packing list

Host x1, power adapter x1, probe x1, software x1, instrument case x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

MUT550B

MUT550B