SANYAN SYSC-150A high-precision Spinning Coater 8000rpm swirl/spin speed

sanyan

sanyan-

Chengyue CY-SPC8-F polytetrafluoride material cavity Spinning Coater + heating baking glue

$ 5475.00 -

SETCAS KW-4A Spinning Coater Manual

$ 1264.00 -

HuiNuo NBC-12TV2 (150 ℃) heating uniform Spinning Coating Machine, high temperature Spinning Coater

$ 5792.00 -

SETCAS KW-4C-I intelligent program-controlled Spin Coater, cover opening protection, adjustable acceleration

$ 6253.00 -

Chengyue CY-SPC4-PP Spinning Coater aluminum alloy structure 10000 rpm, program-controlled homogenization

$ 1582.00

SYSC-150 series high-precision programmable blender (Spin Coater) is a new generation of rotary coating equipment. Driven by precision high-speed servo motor, the speed is up to 12000rpm, and the speed is accurate. The maximum rotational acceleration is up to 60,000 rpm/s (true acceleration with load). Fully automatic program control. Super corrosion resistant, 304 stainless steel body, cavity made of NPP material, rotary table made of PEEK material. Safety protection function, vacuum suction detection, cavity closure detection. It is mainly used in microelectronics, semiconductors, plate making, and new energy

1. Product application

SYSC-150 series high-precision programmable Spin Coater has a maximum speed of 12,000rpm and a maximum rotational acceleration of 60,000rpm (real acceleration under load conditions). It has the characteristics of high speed accuracy, stable speed, excellent acceleration, active speed control, and multi-stage program control of the homogenizing process. Used for the preparation of various high-precision nano-functional coatings in the fields of microelectronics, semiconductors, optoelectronic devices, new energy, biomaterials, optical devices and other fields.

2. Product features

1. The rotary motor adopts a precision high-speed servo motor specially designed for the homogenizer, which has high precision, high stability and high reliability.

2. Excellent rotational acceleration performance, the maximum rotational acceleration can reach 60000rpm/s (real acceleration with load).

3. Two safety interlock functions:

(1) The homogenizing cavity has the detection function of opening and closing, so as to ensure that the cavity can be started only after it is closed, so as to prevent personal injury caused by flyers during the homogenization process;

(2) The vacuum suction sheet has a vacuum detection function, and if a vacuum leak occurs and the substrate cannot be firmly adsorbed, the operation will be stopped immediately.

4. The shell is made of SUS304 stainless steel, which is anti-corrosion, rust-free and easy to clean.

5. The homogenizing cavity is made of German Röchling NPP material, which is molded by CNC integrated processing. Pick up and store the glue that is detached from the substrate to avoid entering the vacuum line and the inside of the equipment. Corrosion-resistant and easy to clean.

6. The rotary suction table is made of German Röchling PEEK material, which is processed by CNC integration. High temperature resistance, corrosion resistance, no deformation.

7. Fully automatic segmentation program control of the homogenizing process. The whole homogenization process can be divided into up to ten stages, and the acceleration time, rotation speed and homogenization time of each section can be precisely controlled and continuously adjusted. 50 sets of process programs can be stored and recalled at any time.

8. 7-inch LCD touch screen makes the control more convenient, and the running status and various parameters are displayed in real time, so that the process of homogenization can be understood more intuitively.

9. The opening and closing of the Vacuum Pump are automatically programmed, no manual operation is required.

10. Add a pre-suction step before rotation, and the "pre-suction time" is up to 99s, to ensure that the substrate is firmly adsorbed on the rotating table before rotating the coating. After the homogenization is completed, the desorption sheet step is added, and the "desorption tablet time" is up to 99s, so as to ensure that the vacuum is cut off after the safe stop, and the substrate is released to prevent the substrate from slipping off after the coating film and causing damage to the film layer.

11. Standard oil-free Vacuum Pump, low noise. The high suction force adheres the substrate tightly to the rotary table, preventing flyers.

3. Technical parameters

Device model Technical parameters | SYSC-150A | SYSC-150B | SYSC-150C |

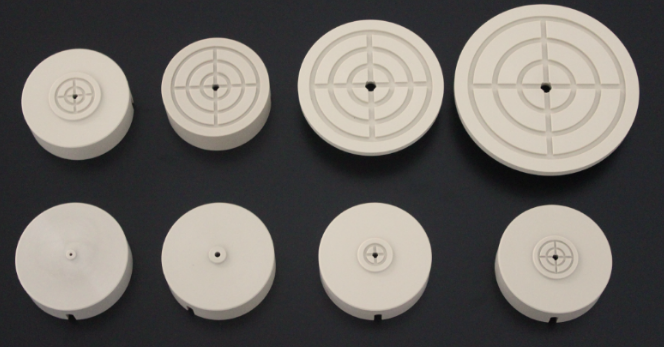

Coated substrate size | Ø10~150mm | Ø10~150mm | Ø10~150mm |

Rotation speed | 10~8000rpm | 10~10000rpm | 10~12000rpm |

RPM resolution | 1rpm | 1rpm | 1rpm |

Speed accuracy | <0.02% | <0.02% | <0.02% |

Spin coating acceleration* | 0~40000rpm/s | 0~50000rpm/s | 0~60000rpm/s |

Acceleration time for each segment | 999.9s | 999.9s | 999.9s |

Spin coating time per period | 9999.9s | 9999.9s | 9999.9s |

Temporal resolution | 0.1s | 0.1s | 0.1s |

Pre-aspiration tablet time | 99s | 99s | 99s |

Deabsorption tablet time | 99s | 99s | 99s |

* The maximum spin coating acceleration is the actual acceleration under load (using ≤ Ø80mm substrate).

sanyan SYSC-150A High-precision Spinning coaterSpecifications

| LIST | VALUE |

|---|

sanyan SYSC-150A High-precision Spinning coater Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.