Falling ball impact test instrument, Dutch TQC SP1891 standard ISO 6272-1 and ASTM D2794

The TQC drop ball impact test instrument SP1891 is an imported drop ball impact test instrument that meets ISO and ASTM international standards. The standard drop ball diameter of the SP1891 Impact instrument is 15.9mm.

TQC sheen

TQC sheen-

JINGKELIAN QCJ-40 Wood Impact Machine 40cm/500g GB/T 4893.9

$ 198.00 -

JINHE XJL-300B-1 Touch Screen Pipe Drop Hammer Impact Tester Double Pipe Guide Structure

$ 3545.00 -

JINGKELIAN QCJ-120 film impact test 120cm/1000g GB/T 1732

$ 362.00 -

PUSHEN ZCJ-II Heavy Impact film impact resistance testing machine

$ 1051.00 -

YONGLIDA QCJ-120 Film Impact Device 120cm/1000g GB/T1732

$ 340.00

Falling Ball Impact Tester SP1891 Overview

The Dutch TQC falling ball impact Tester SP1891 is an imported falling ball impact Tester designed and manufactured in accordance with the international standards ISO 6272-1 and ASTM D2974. It is suitable for testing the impact resistance of paint films, paint coatings, etc. The base of the falling ball impact Tester SP1980 has a built-in bubble level to ensure that the impact Tester is placed in the correct position. Dual scales on the catheter. The falling ball impact Tester SP1891 is approved for testing by Qualicoat, QIB and GSB laboratories.

Falling ball impact Tester SP1891 application standard

Comply with international standards: ISO 6272:1993, EN 12206-1:2004, AAMA 2605-05, Qualicoat 2006, Qualisteelcoat 2008, etc.

* The standards that meet the requirements depend on the type of impact testing machine, and other standards can be applied by changing the device combination.

Falling ball impact Tester SP1891 installation method

â Place on a level surface

â There must be at least 2.2 meters of free height on the work surface

â The temperature and humidity of the test environment must meet the standards

â Specific steps for installing the falling ball impact Tester SP1981

1) Choose the appropriate weight for experimental testing

2) Place the punch on the bracket on the floor plate

3) Put the height limit ring on the pipe

4) Push the height limit ring and weight to the bottom, turn the height limit ring lever to block the weight

5) Tighten the fixing button to fix the height limit ring

6) Install the conduit with the height limit ring and weights on the assembly base

7) Hold the weight, turn the lever to loosen the height limit ring, and raise the height limit ring to the starting height required for the test test

8) Press the red button, raise the punch and place the test board on the base

9) Hold the catheter while turning the handle to release the catheter. Move the catheter until the weight line and the 0 scale line of the catheter are on a horizontal line

10) At this time, the installation of the falling ball impact Tester SP1981 is completed.

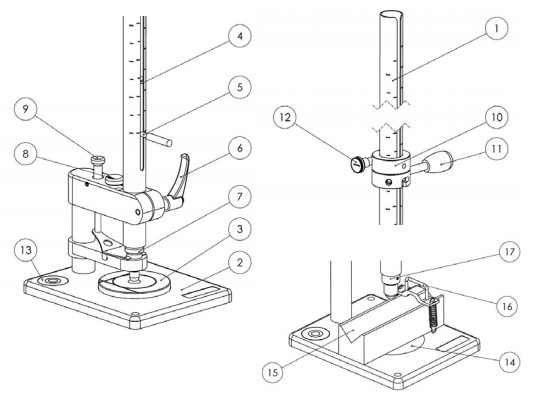

Display diagram of falling ball impact Tester SP1981

Differences in functional structure diagram of TQC series impact Tester

| serial number | Part Name | SP1880 | SP1890 | SP1891 | SP1895 |

| 1 | catheter | â | â | â | â |

| 2, 6, 13 | Base with built-in bubble level | â | â | â | â |

| 3 | 16.3mm die | â | â | ||

| 3 | 27.0mm die | â | â | ||

| 4 | 1kg weight | â | â | ||

| 5 | Heavy hammer | â | â | â | â |

| 7 | 15.9mm diameter punch | â | â | â | |

| 8 | 12.7mm diameter punch | â | |||

| 9 | lift release punch | â | |||

| 10,11,12 | height limit ring | â | â | â | â |

| 14,15,16 | V-notch vise with spring clamp | ||||

| 17 | weight | â | â |

Impact Tester functional structure diagram

TQC sheen SP1891 Impact test instrumentSpecifications

| LIST | VALUE |

|---|---|

| Drop Weight Mass | 900g、1000g |

| Striker Diameter | Φ15.9mm、Φ20mm |

| die base aperture | Φ16.3mm、Φ27mm |

| Standards | ISO 6272:1993、EN 12206-1:2004、AAMA 2605-05、Qualicoat 2006、Qualisteelcoat 2008Ω. |

| Height limit ring | Yes. |

| Bubble level | Built-in base |

TQC sheen SP1891 Impact test instrument Packing list

Base (including level) x1, duct x1, height limit ring x1, punch (20mm) x1, punch (15.9mm) x1, die (diameter 27mm) x1, die (diameter 16.3mm) x1, falling body (1KG) x1, falling body (0.9KG) x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- General Impact Test for Paints and Coatings - ASTM D2794

- Discussion on Impact Strength of Paint Film and Its Influencing Factors

- ActiveJJF 002-2015

- ActiveSH/T 3022-2019

- Active 10302-2023

- ActiveASTM

- ActiveJT/T 821.1-2011

- ActiveDL/T 2308-2021

- ActiveJG/T 224-2007

- ActiveHG/T 5060-2016

- ActiveHG/T 4338-2012

- Active 0025-2018

- ActiveHG/T 5176-2017

- ActiveHG/T 5059-2016

- ActiveDB 44/T 1106-2012

- ActiveDB 44/T 1024-2012

- ActiveHG/T 5368-2018

- ActiveHG/T 4568-2013

- ActiveHG/T 4770-2014

- Active 2421-2022

- Active 2422-2022

- ActiveHG/T 4336-2012

SP1891

SP1891

SP1895

SP1895

SP1890

SP1890

SP1880

SP1880