RUNJIE RJTS800S digital Ultrasonic Flaw Detector, Speed of sound 1000~9999m/s

High-precision quantitative positioning, Automatic calibration, free switching of three kinds of rulers, with gain compensation, oil-proof, waterproof and dustproof functions; built-in gate sound and light alarm, support screen freezing and thawing.

RunJie

RunJie-

RUNJIE CDX-3 Magnetic Particle Flaw Detector Portable nondestructive testing instrument

$ 639.00 -

LEEB leeb610 Magnetic Particle Flaw Detector Magnetization Pole Distance 0~220mm

$ 390.00 -

WENTAI HY-30 Ultrasonic Flaw Detector DAC Linear dispersion automatically generates 6 meters range

$ 2106.00 -

KAIRDA NDT650 Ultrasonic Flaw Detector high gain 130dB intelligent calibrating

$ 1563.00 -

WENTAI WT-9HS Portable eddy current Flaw Detector Metal crazing detection 64Hz-2MHz

$ 10242.00

Introduction

The RJTS800S digital ultrasonic flaw Detector can detect, locate, evaluate and diagnose various internal defects such as cracks, welds, pores, sand holes, inclusions, folds, etc. quickly, conveniently, without damage, and accurately. It is widely used in electric power, petrochemical, Boiler pressure vessel, steel structure, military industry, aerospace, railway transportation, automobile, machinery and other fields. It is the required instrument for the non-destructive testing industry.

The main function

● High-precision quantification and positioning, meeting the requirements of short-term and long-distance flaw detection;

● The near-field blind zone is small, which meets the requirements for flaw detection of small-diameter and thin-walled pipes;

● Automatic calibration: one-button automatic calibration, very convenient operation, automatic testing of the "zero point", "K value", "leading edge" of the probe and the "sound velocity" of the material;

● Automatically display defect echo position (depth d, level p, distance s, amplitude, equivalent dB, aperture ф value);

● Freely switch between three scales (depth d, level p, distance s);

● Automatic gain, echo envelope, and peak memory functions improve the efficiency of flaw detection;

● φ value calculation: Forging flaw detection with straight probe, find the highest defect wave and automatically convert the aperture φ value, and automatically calculate the large flat bottom;

● 15 independent flaw detection channels (expandable), free to input and store flaw detection standards of any industry, no need to carry test blocks for on-site flaw detection;

● Free storage and playback of 50 A-scan waveforms and data;

● DAC and AVG are automatically generated and can be produced in sections, and the sampling points are not limited, and can be corrected and compensated;

● 3 built-in flaw detection standards can be called out;

● Can freely input any industry standard;

● The emission pulse width and intensity are adjustable;

● 260,000-color true color screen with super bright display and adjustable brightness, suitable for Operating Environments with strong light and low light;

● Powered by high-performance, safe and environment-friendly lithium battery, it can work continuously for 8 hours.

● Real-time clock record: real-time flaw detection date and time tracking record and storage;

● Power-down protection, the stored data will not be lost;

● Flaw detection parameters can be automatically tested or preset;

● Digital suppression, does not affect gain and linearity;

● Gain compensation: Db attenuation caused by factors such as surface roughness, curved surface, and long-distance flaw detection of thick workpieces can be corrected;

● It has three anti-water, oil-proof and dust-proof functions, and its service life is extended, which is several times that of conventional flaw Detectors.

Important Accessibility

● Two input methods of angle and K value;

● Analysis of echo times;

● Power status indication;

● Gate sound and light alarm;

● DAC sound and light alarm;

● Freezing and unfreezing of the screen;

● Clock display.

Optional

1. PC ultrasonic flaw Detector communication software

2. Standard test block

3. Coupling agent

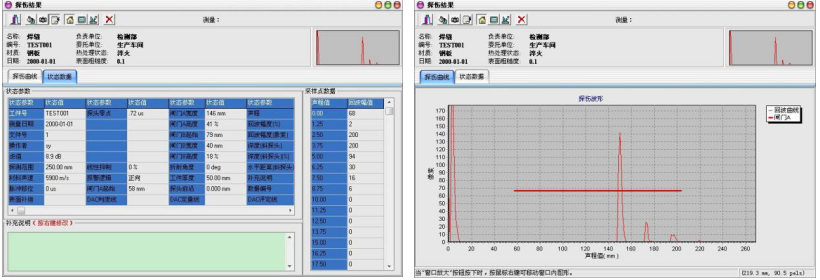

Software display diagram

RunJie RJTS800S Digital Ultrasonic Flaw DetectorSpecifications

| LIST | VALUE |

|---|---|

| screen display | monochrome |

| Scanning range | 0~6000mm steel longitudinal wave |

| operating frequency | 0.4MHz15MHz |

| Vertical linearity error | ≤4% |

| Horizontal linearity error | ≤0.2% |

| Gain | 110dB |

| Sensitivity margin | > 60dB (deep 200mm Φ2 flat bottom hole) |

| resolution | >32dB(5N20) |

| dynamic range | ≥30dB |

| channel | 100 groups |

| storage | 500 pairs of A sweeps |

| DAC/AVG Linear dispersion | Yes. |

| TCG Linear dispersion | without |

| B-scan | without |

| PC communication | Yes. |

| flaw detection video | Yes. |

| Pulse/Emission Intensity | Iradjustable |

| Noise level: | <8% |

| Sexual repeability emission frequency | 100~1000HZ |

| Sound speed range | 1000~9999m/s |

| Operating Mode | Straight Probe, Oblique Probe, Dual Crystal, Penetration |

| digital suppression | (0~80) %, does not affect linearity and gain |

| Operating Time | Continuous work for more than 8 hours (lithium battery) |

| Environment temperature | (-20~70) ℃ (reference value) |

| Relative Humidity | (20~95)% RH |

| Three-proof function | Yes. |

| Appearance size | 265 × 160 × 53mm (host) |

| Weight | 1150g |

| Standard configuration | Host, power adapter, straight probe, oblique probe, probe cable |

| Optional accessories | Communication software, data cable, flaw detection test block, computer |

RunJie RJTS800S Digital Ultrasonic Flaw Detector Packing list

Host x1, straight probe x1, oblique probe x1, 9V power adapter x1, probe cable x1, product Encasement box x1, instruction manual x1, certificate x1, packing card x1, warranty card x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What is an ultrasonic flaw Detector?

- The role and application of ultrasonic flaw Detector

- Ultrasonic Flaw Detectors: the right-hand man for nondestructive detection

- Application of Ultrasonic Flaw Detector

RJTS800S

RJTS800S